307-615

14

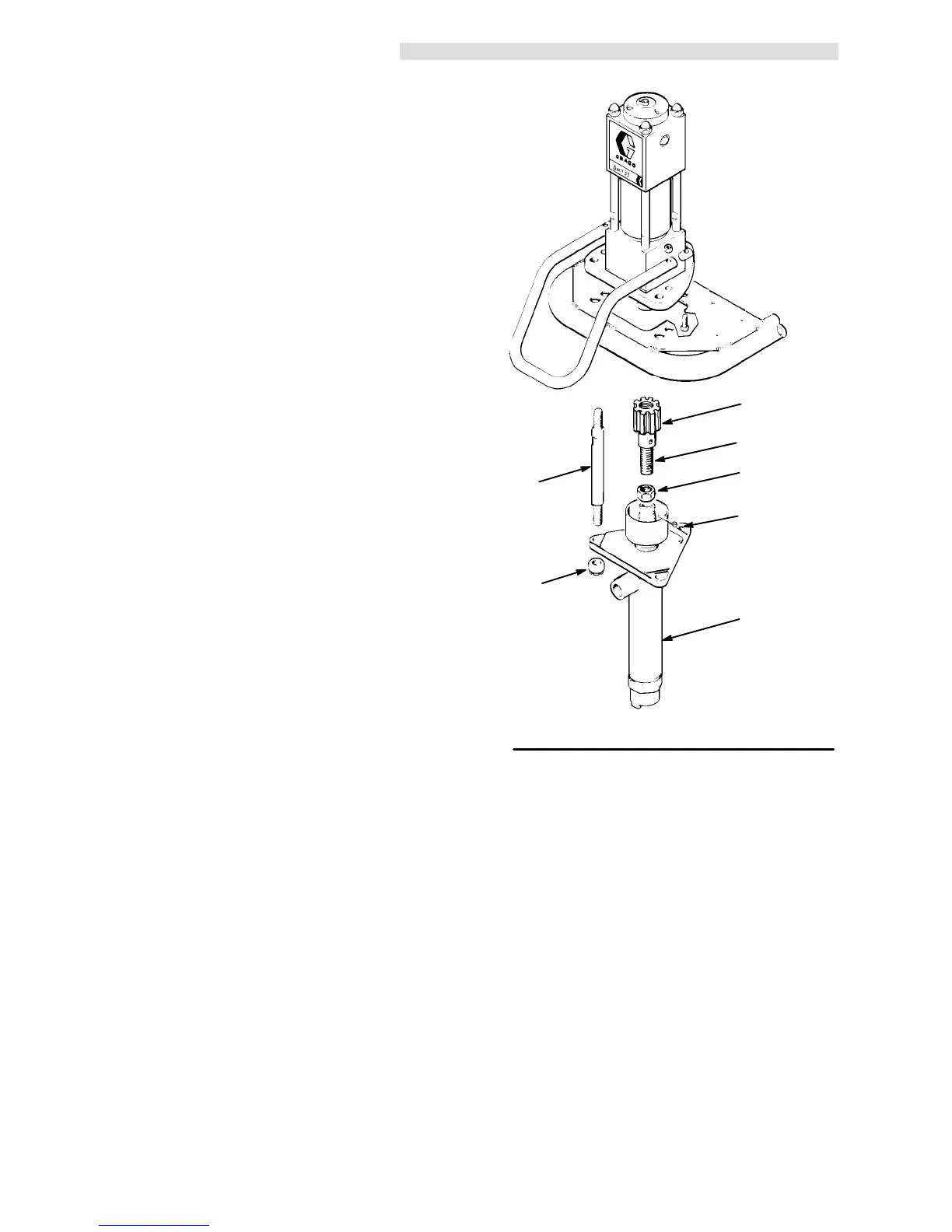

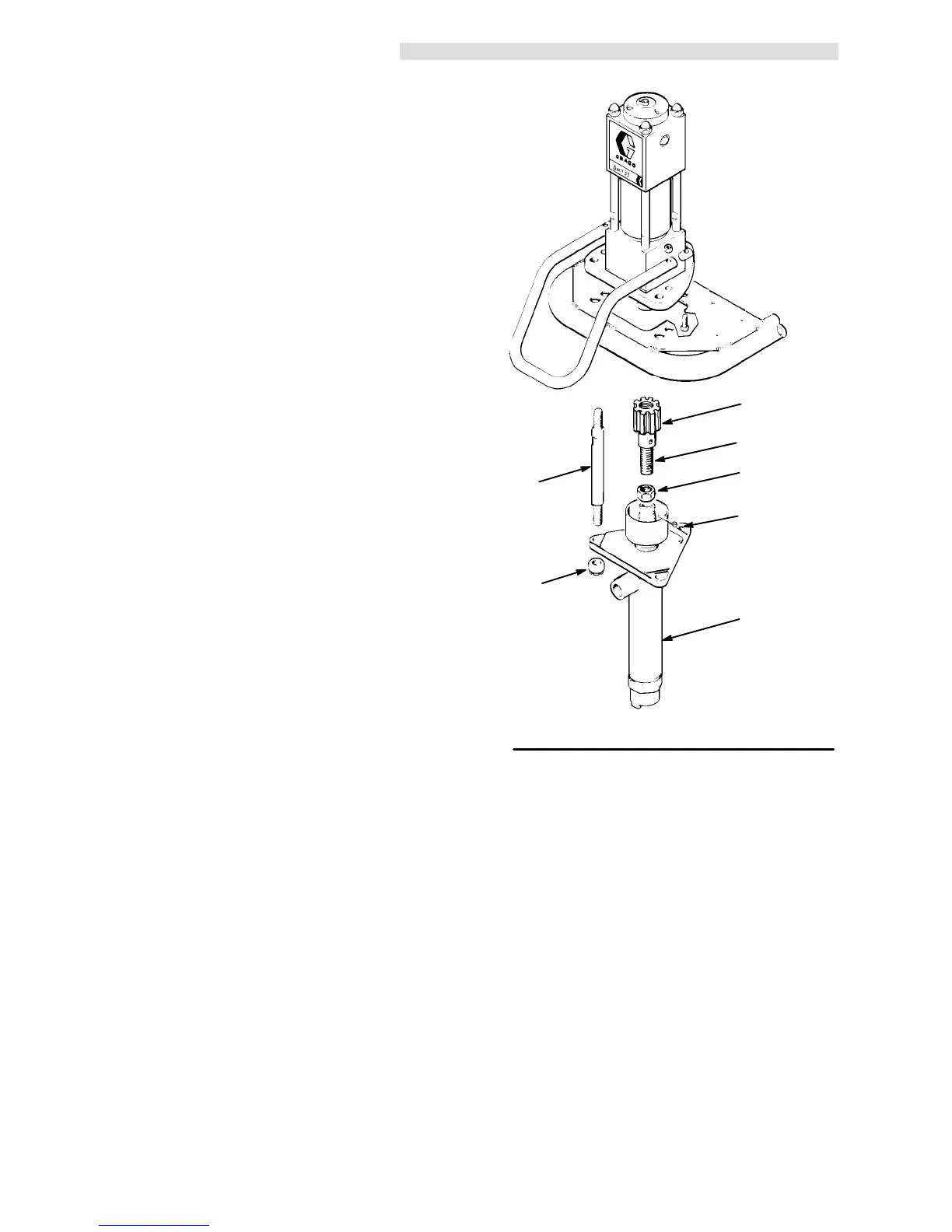

DISPLACEMENT PUMP SERVICE

Disconnect

the Displacement Pump

1. Flush the pump if possible. Stop the pump on the

down

stroke.

2. Follow

the

Pressure Relief Procedure W

arning

on

page

1

1.

3. Remove the suction tube and fluid hose from the

displacement

pump.

4. Unscrew

the three tie rod locknuts (48). See Fig

14.

5. Unscrew

the shouldered nut (35). Pull the displace

-

ment pump (46) of

f the tie rods (47).

6. Screw the jam nut (90) up onto the connecting rod

(91).

7. Remove the lower cotter pin (89) and unscrew the

connecting

rod (91) from the displacement rod (A).

8. Refer

to separate manual

307–862

for displacement

pump

repair instructions. Repair kit 206–735 is

avail

-

able.

Reconnecting

the Displacement Pump

1. Screw

the connecting rod (91) into the displacement

rod

(A) and replace the lower cotter pin (89). Screw

the jam nut (90) all the way down. See Fig 14.

2. Mount

the displacement pump (46) onto the tie rods

(47).

3. Screw the shouldered nut (35) onto the hydraulic

motor (29). Screw the tie rod locknuts (48) onto the

tie

rods (47) and torque to 35–50 ft-lb (47–68 N.m).

4.

Reattach the hoses to the displacement pump.

5. If the grounding wire was disconnected before

service,

be sure to reconnect it before operating the

sprayer.

6. Start

the pump and operate it slowly to check the tie

rods

for binding. Adjust the tie rod locknuts, if neces

-

sary

to eliminate binding.

Fig 14

47

48

35

91

90

89

46

TORQUE

T

O

35–50 ft-lb

(47–68 N.m)

Loading...

Loading...