12 308573

Maintenance

Lubrication

Do not lubricate the air line or air valve. Excessive

lubrication can cause the pump to malfunction.

Flushing and Storage

Flush the pump often enough to prevent the fluid you are

pumping from drying or freezing in the pump and

damaging it. Flush with a fluid that is compatible with the

fluid you are pumping and with the wetted parts in your

system. Check with your fluid manufacturer or supplier for

recommended flushing fluids and flushing frequency.

Always flush the pump and relieve the pressure before

storing it for any length of time.

Grounding Continuity Check

Check your system electrical continuity regularly to be

sure proper grounding is maintained.

Tightening Threaded Connections

Before each use, check all hoses for wear or damage, and

replace as necessary. Check to be sure all threaded

connections are tight and leak–free.

Check fasteners. Tighten or retorque as necessary.

Although pump use varies, a general guideline is to

retorque fasteners every two months. See Torque

Sequence, page 22.

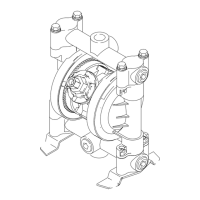

Tightening the Clamps

When tightening the clamps (109), apply thread lubricant

to the bolts and be sure to torque the nuts (110) to 80 to

90 in–lb (9 to 10 N•m). See Torque Sequence, page 22.

See Fig. 7.

Apply thread lube to bolts and torque nuts to 80 to 90 in–lb (9 to

10 N•m). See Torque Sequence, page 22.

Fig. 7

Preventive Maintenance Schedule

Establish a preventive maintenance schedule, based on

the pump’s service history. This is especially important for

prevention of spills or leakage due to diaphragm failure.

WARNING

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 10.

1

Loading...

Loading...