6 308573

Installation

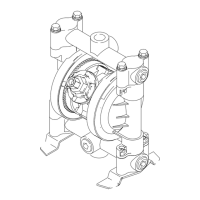

Example of a Gear Oil Receiver Evacuation System

Fig. 2

Fig. 3

9249A

H

A

C

D

G

J

L

Y

F

B

E

J

J

J

J

J

J

K

K

K

KEY

A Pump air regulator

B Air line quick coupler (required)

C Fluid drain valve (required)

D Control valve

E Suction wand

F Suction hose

G Fluid quick coupler

H Husky 716 pump

J Electrically conductive, bonded air

supply line

K Electrically conductive, bonded fluid

line to pump

L Electrically conductive, bonded

wasteoil linetostorage tank

Y Ground wire (required; See page 4

for installation instructions. Pump

must be properly grounded and

entire system electrically bonded.)

Bay 1

Bay 2

Bay 3

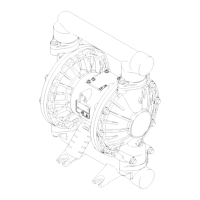

9250A

Example of a Waste Oil Evacuation

System, or General Fluid Transfer

Application

Shown with fluid inlet and outlet ports facing

forward (see page 8).

NOTE: Air inlet restrictor may be removed

for higher flow capabilities.

KEY

A Pump air regulator

B Air line quick coupler (required)

C Fluid drain valve (required)

D Wall-mount bracket (Part No. 224835)

F Electrically conductive suction hose

G Fluid quick coupler

H Husky 716 pump

J Electrically conductive, bonded air supply line

L Electrically conductive, bonded waste oil line to storage

tank M Waste oil receiver

S 90° Elbow (required for wall mount applications)

Y Ground wire (required; See page 4 for installation

instructions. Pump must be properly grounded and

entire system electrically bonded.)

Loading...

Loading...