Why is my Graco Paint Sprayer hydraulic pump so noisy?

- SStephanie WangSep 3, 2025

If there is excessive hydraulic pump noise in your Graco Paint Sprayer, it may be due to: * A low hydraulic fluid level. Shut off the sprayer and add fluid.

Why is my Graco Paint Sprayer hydraulic pump so noisy?

If there is excessive hydraulic pump noise in your Graco Paint Sprayer, it may be due to: * A low hydraulic fluid level. Shut off the sprayer and add fluid.

What causes low stall pressure on Graco LineLazer IV 200HS?

If you observe low stall or run pressure shown on the display of your Graco Construction Equipment, it might be due to: * A new pump or new packings, where the pump break-in period takes up to 100 gallons of material. * A faulty transducer, so replace it.

What to do if the gallon counter on my Graco Paint Sprayer isn't working?

If the gallon counter on your Graco Paint Sprayer is not working, check these potential causes: * A broken or disconnected wire. Check the wires and connections, and replace any broken wires. * A bad sensor. Replace the sensor. * A missing or damaged magnet. Replace the magnet and locate it in the correct spot.

Why is the fluid delivery low on my Graco LineLazer IV 200HS Construction Equipment?

If your Graco Construction Equipment fluid delivery is low, consider the following: * Increase the pressure if the pressure setting is too low. * Clean the displacement pump outlet filter (if used) if it is dirty or clogged. * Tighten the intake line to the pump inlet if it is not tight. * Use a larger diameter or shorter hose if there is a large pressure drop in the fluid hose.

How to fix distance counter on Graco LineLazer IV 200HS Construction Equipment?

To fix the distance counter not operating properly on your Graco Construction Equipment: * Refer to “Spray icon does not show on display when fluid is sprayed” if the trigger sensor is not set correctly. * Check the connector and reconnect if there are bad wiring connections. * Adjust the space between the sensor and gear to .050 -/+ .020 in. if the distance sensor is not spaced correctly from the gear. * Remove the tire and press in or pull out the gear to align the sensor and gear if the distance sensor and gear are not aligned. * Replace the distance gear/wheel if gear teeth are missing or damaged. * Replace the sensor if the wire is cracked or broken.

What to do if displacement pump output is low on Graco Construction Equipment?

To address displacement pump operates, but output is low on upstroke on your Graco Construction Equipment, service the piston ball if it is not seating or replace the packings if piston packings are worn or damaged.

What to do if spray icon doesn't show on my Graco Paint Sprayer display?

If the spray icon does not show on the display when fluid is sprayed from your Graco Paint Sprayer, consider the following: * A connector may be loose. Check that the 5-pin connector and reed switch are properly connected. * The interrupter may be improperly positioned. Turn the screw counterclockwise until the spray icon synchronizes with fluid spray. * The reed switch assembly may be damaged. Replace the reed switch assembly. * The magnet on the assembly may be missing. Replace the reed switch assembly. * A connector on the wiring harness or on the reed switch may be damaged. Disconnect the reed switch and 5-pin connector from the back of the control board. Check continuity between pin 1 on the 2-pin connector and pin 1 on the 5-pin connector, and between pin 2 on the 2-pin co...

Why is the fluid delivery low on my Graco Paint Sprayer?

If the fluid delivery is low on your Graco Paint Sprayer, here are some possible causes and solutions: * The pressure setting may be too low. Increase the pressure. * The displacement pump outlet filter (if used) may be dirty or clogged. Clean the filter. * The intake line to the pump inlet may not be tight. Tighten it. * The hydraulic motor may be worn or damaged. Bring the sprayer to a Graco distributor for repair. * There may be a large pressure drop in the fluid hose. Use a larger diameter or shorter hose.

Why is there excessive paint leakage in my Graco Paint Sprayer?

If you notice excessive paint leakage into the throat packing nut of your Graco Paint Sprayer, check the following: * The throat packing nut may be loose. Remove the throat packing nut spacer and tighten the throat packing nut just enough to stop the leakage. * The throat packings may be worn or damaged. Replace the packings. * The displacement rod may be worn or damaged. Replace the rod.

How to prime a Graco Paint Sprayer if it's difficult?

If you're finding it difficult to prime the pump on your Graco Paint Sprayer, consider the following: * There may be air in the pump or hose. Check and tighten all fluid connections. Reduce engine speed and cycle pump as slowly as possible during priming. * The intake valve may be leaking. Clean the intake valve, ensuring the ball seat is not nicked or worn and that the ball seats well. Reassemble the valve. * The pump packings may be worn. * The paint may be too thick. Thin the paint according to the supplier’s recommendations. * The engine speed may be too high. Decrease the throttle setting before priming the pump.

Critical safety information regarding fire, health, and operational hazards.

Information on selecting and using spray tips for different materials.

Basic principles for equipment repair and grounding procedures.

Steps for pressure relief, periodic checks, and trigger lock usage.

Solutions for operational problems and caster wheel adjustments.

Procedures for adjusting the can actuator for optimal dot size.

Removal and installation of key electrical system components.

Steps for removing and installing the pressure control transducer.

Understanding display codes for system status and faults.

Guide for replacing the distance sensor on the sprayer.

Detailed steps for servicing the hydraulic pump.

Steps for replacing the fan belt.

Procedures for engine removal and installation.

Steps for rebuilding the hydraulic motor.

Steps for changing hydraulic oil and filters.

Procedures for removing and installing the gallon counter.

Procedures for removing and installing the displacement pump.

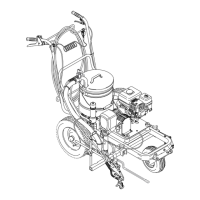

Visual guide to component locations and parts pages.

Comprehensive list of all parts with reference numbers and descriptions.

Electrical schematic for the Auto-Layout system components.

Key performance and physical specifications of the sprayer.

Manufacturer warranty details and contact information.

| Engine | Honda GX160 |

|---|---|

| Operating Pressure | 2000 PSI |

| Power Source | Gasoline |

| Material | Steel |

| Max Flow Rate | 0.54 GPM |

| Flow Rate | 0.54 GPM |

| Paint Capacity | 5 gal (19 l) |

| Hose Length | 50 feet |

| Max Operating Pressure | 3300 psi |

Loading...

Loading...