Hydraulic Motor Replacement

3A3394E Repair - Parts 23

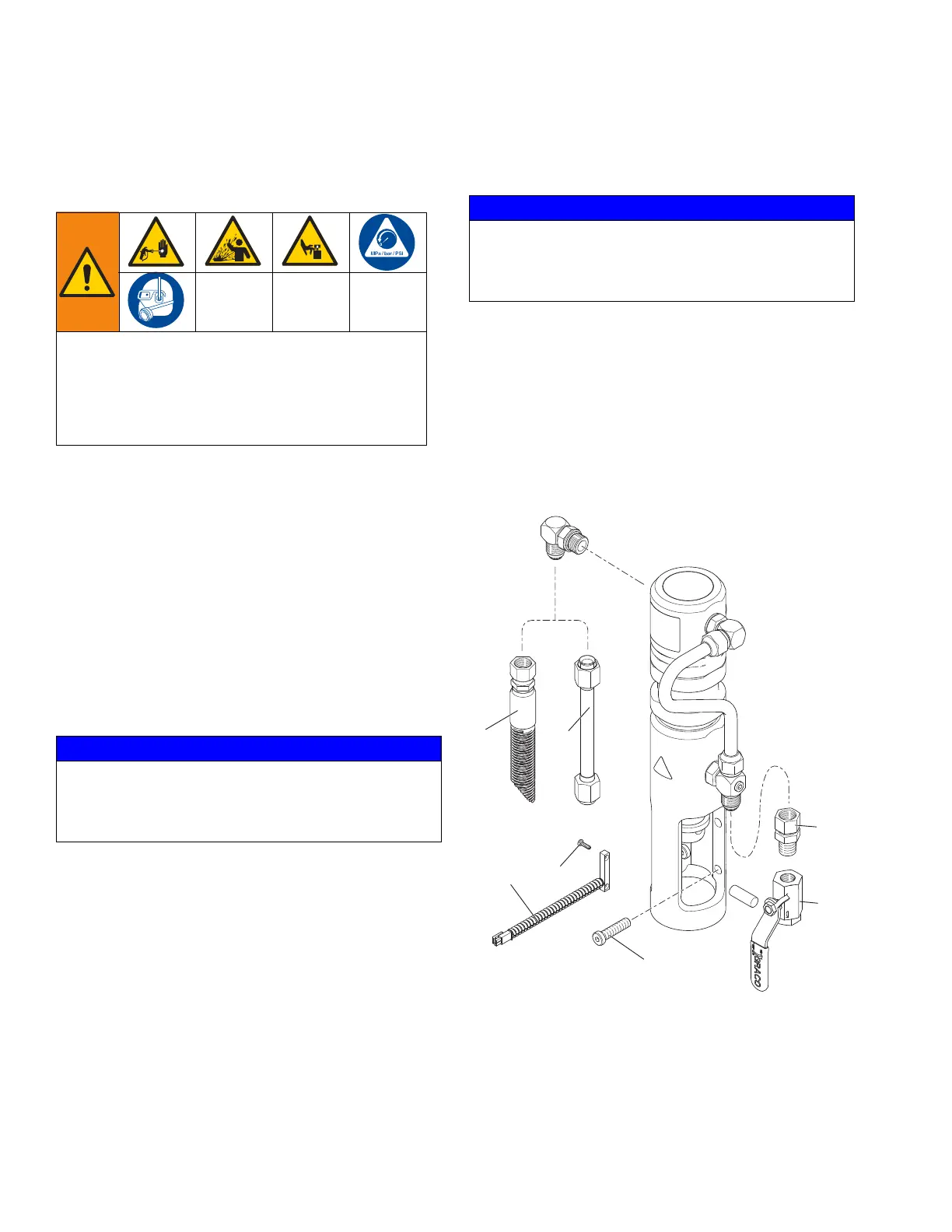

Hydraulic Motor

Replacement

Removal

1. Perform Pressure Relief Procedure, page 10.

2. Remove paint pump, see Paint Pump Replace-

ment, page 22.

3. Disconnect fitting (108) above ball valve (109).

NOTE: Oil will spill out of hoses. Have rags and

waste pail nearby.

4. Disconnect hose (74) for pump 1 or tube (98) for

pump 2.

5. Disconnect pump counter (112) with 2 screws (113).

6. Remove four mounting bolts (116) from hydraulic

motor and remove motor from sprayer.

Installation

1. Install hydraulic motor with four mounting bolts (116).

2. Install pump counter (112) with two screws (113).

3. Connect hose (74) or tube (98) to fitting.

4. Connect fitting (108) above ball valve (109).

5. Install paint pump, see Paint Pump Replacement,

page 22.

6. Purge hydraulic system, see Hydraulic System

Purging, page 13.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

NOTICE

Use a screwdriver to lift pump piston up to gain access

to mounting bolts and avoid contact with piston. Con-

tact with pump mounting bolts can scratch and damage

the pump piston.

NOTICE

Use a screwdriver to lift pump piston up to gain access

to mounting bolts and avoid contact with piston. Con-

tact with pump mounting bolts can scratch and damage

the pump piston.

74

109

Loading...

Loading...