308685

Rev. J

INSTRUCTIONS–PARTS LIST

INSTRUCTIONS

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

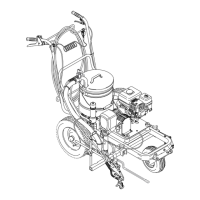

GM3000

GASOLINE-POWERED AIRLESS LINESTRIPER

LineLazer 3000

3000 psi (210 bar, 21 MPa)

Maximum Working Pressure

Model 232650, Series A

Model 233010, Series A

Patent Pending

CAUTION

Always use a minimum hose length of 25 foot

(7.5 m) 1/4 inch ID. An undersized hose may result

in poor equipment performance and damage to the

clutch.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1996, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

06941B