Operation

332245G 13

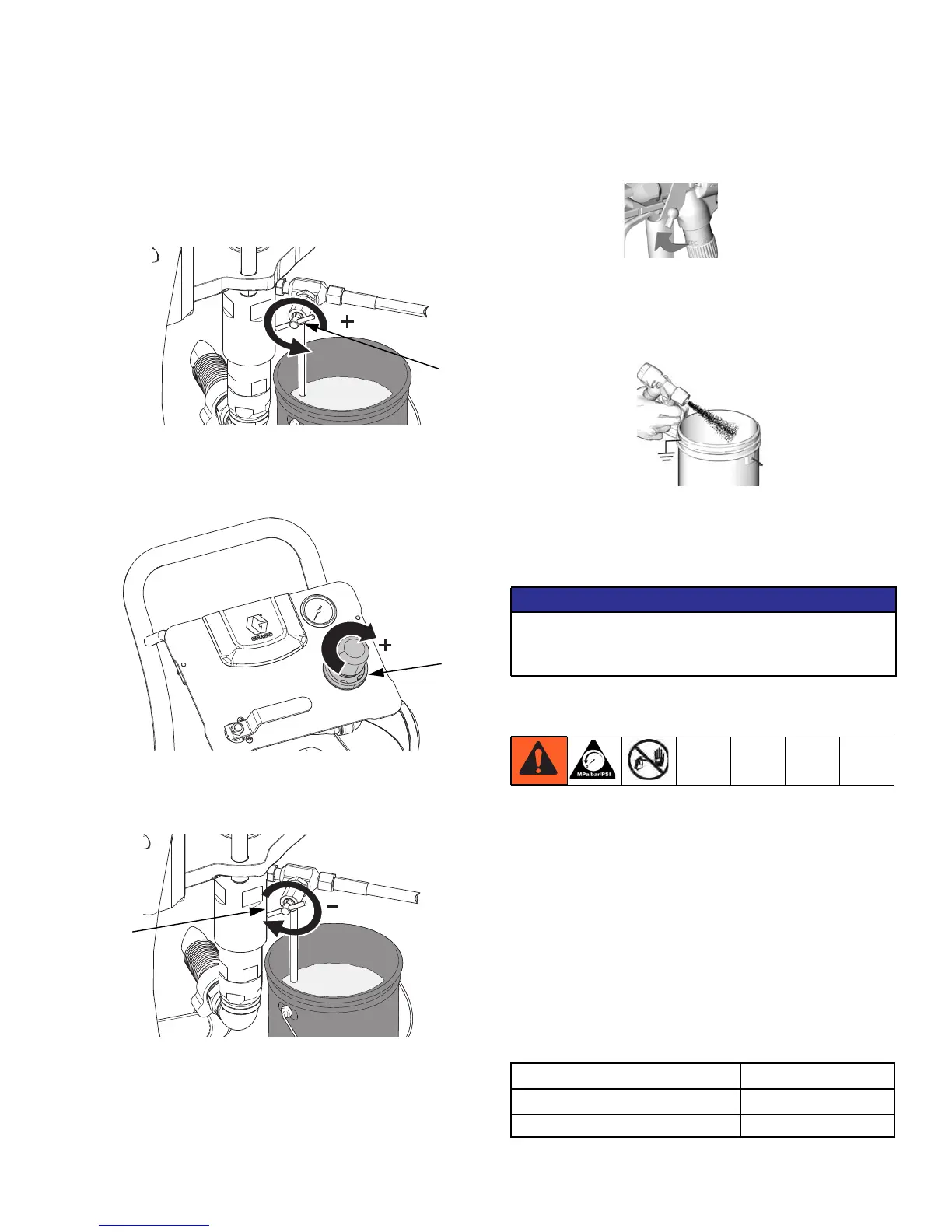

6. Prime through drain valve, if necessary (usually for

one component, high viscosity materials):

a. Place drain tube in a grounded waste pail.

Open drain/purge valve (S) slightly by rotating

counterclockwise.

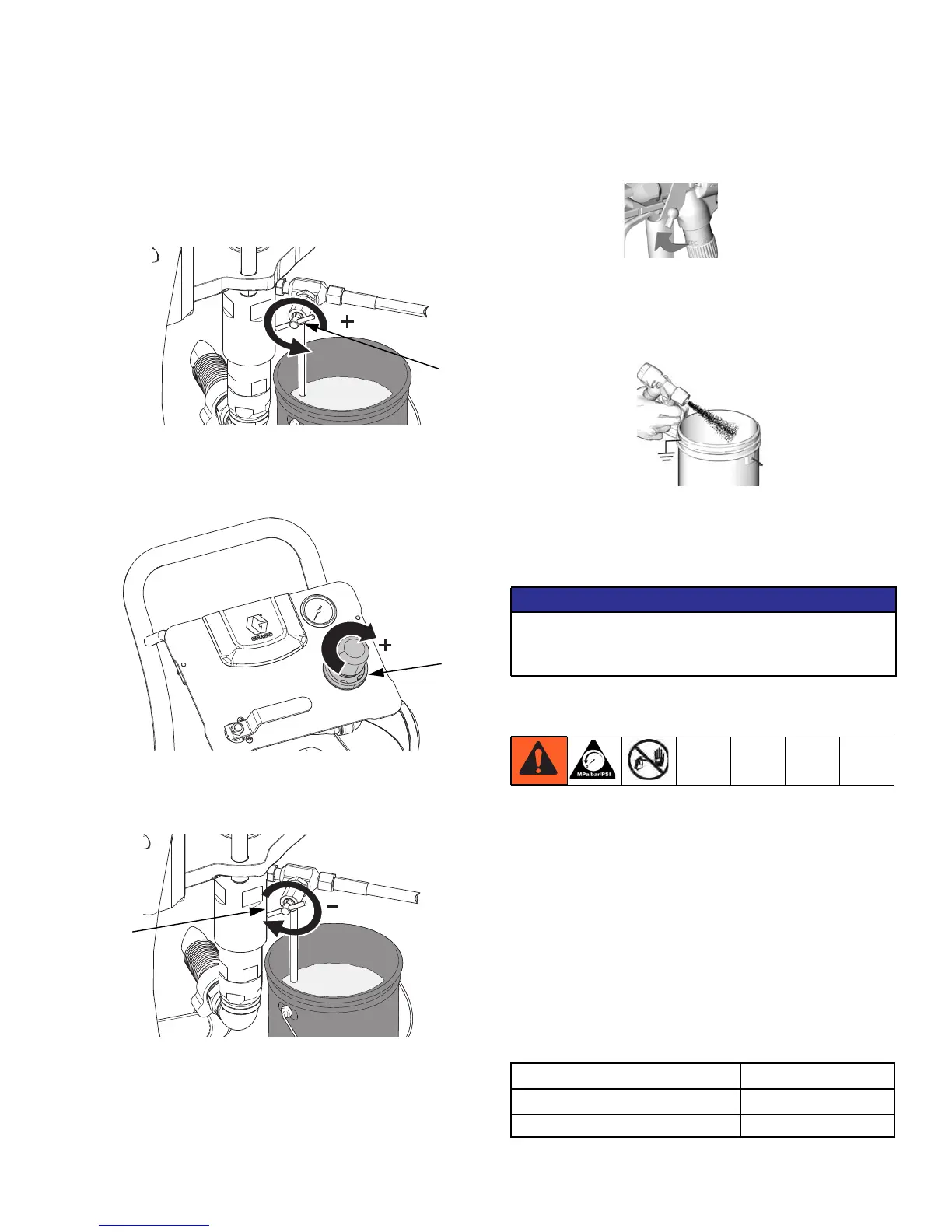

b. Start the pump by rotating the air regulator

adjustment knob (E) clockwise until pump

begins to move.

c. When clean material flows from drain tube close

drain/purge valve (S) by rotating clockwise.

Pump will stall.

7. Prime hose and gun:

a. Disengage gun trigger lock.

b. Trigger gun slowly open regulator adjustment

knob (E) until pump begins to cycle. Trigger gun

into grounded pail until a steady stream comes

from gun.

c. Engage trigger lock.

8. Equipment is now ready to spray; go to Spray, page

14.

Install the Spray Tip

Follow Pressure Relief Procedure, page 10. Install the

spray tip and tip guard as explained in your separate

gun manual, supplied.

The fluid output and pattern width depend on the size of

the spray tip, the fluid viscosity, and the fluid pressure.

Use the Spray Tip Selection Chart in your gun instruc-

tion manual as a guide for selecting an appropriate

spray tip for your application.

Maximum Tip Size

Larger tips can be used with less viscous material.

S

ti21107a

E

ti21108a

S

ti21109a

NOTICE

Do not prime pump through drain valve using two

component materials. Mixed two component materi-

als will harden in valve and result in clogging.

Model Maximum Tip Size

Merkur X72 0.021

Merkur X48

0.025

TI5048a

TI8727a

Loading...

Loading...