Maintenance

26 3A4702E

Maintenance

Routine maintenance is important to ensure proper operation of your sprayer.

Cleaning Outlet Valves

Dirt and debris in the outlet valve assemblies

may affect sprayer performance and require

cleaning. Perform these steps ONLY if the

sprayer is not working and other

troubleshooting measures have not

resolved the issue.

1. Perform Pressure Relief Procedure,

page 11.

2. Unplug the Power Cord.

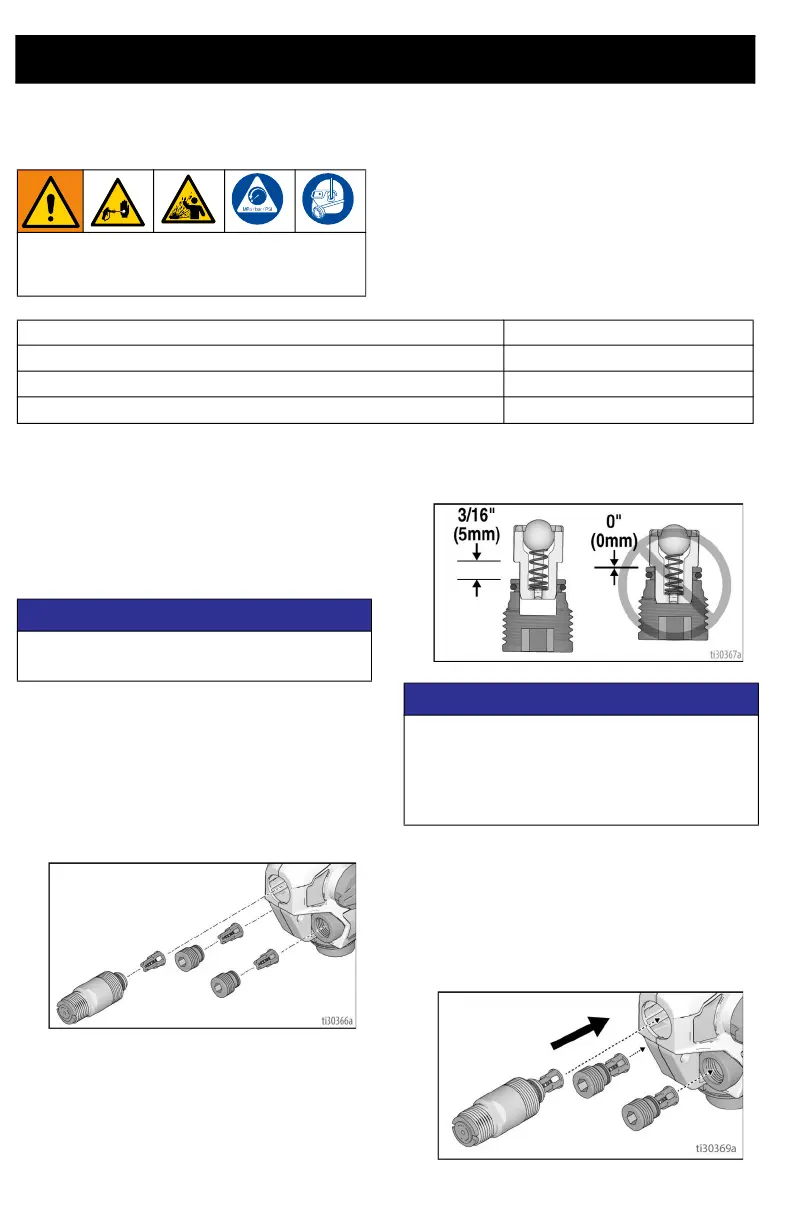

3. To clean the three outlet valves, remove

two pump plugs and front valve.

Remove pump plugs with 8mm or 5/16”

Allen wrench.

4. Clean outlet valve assemblies with

warm water or mineral spirits.

5. Check ball should move freely against

the spring in the retainer.

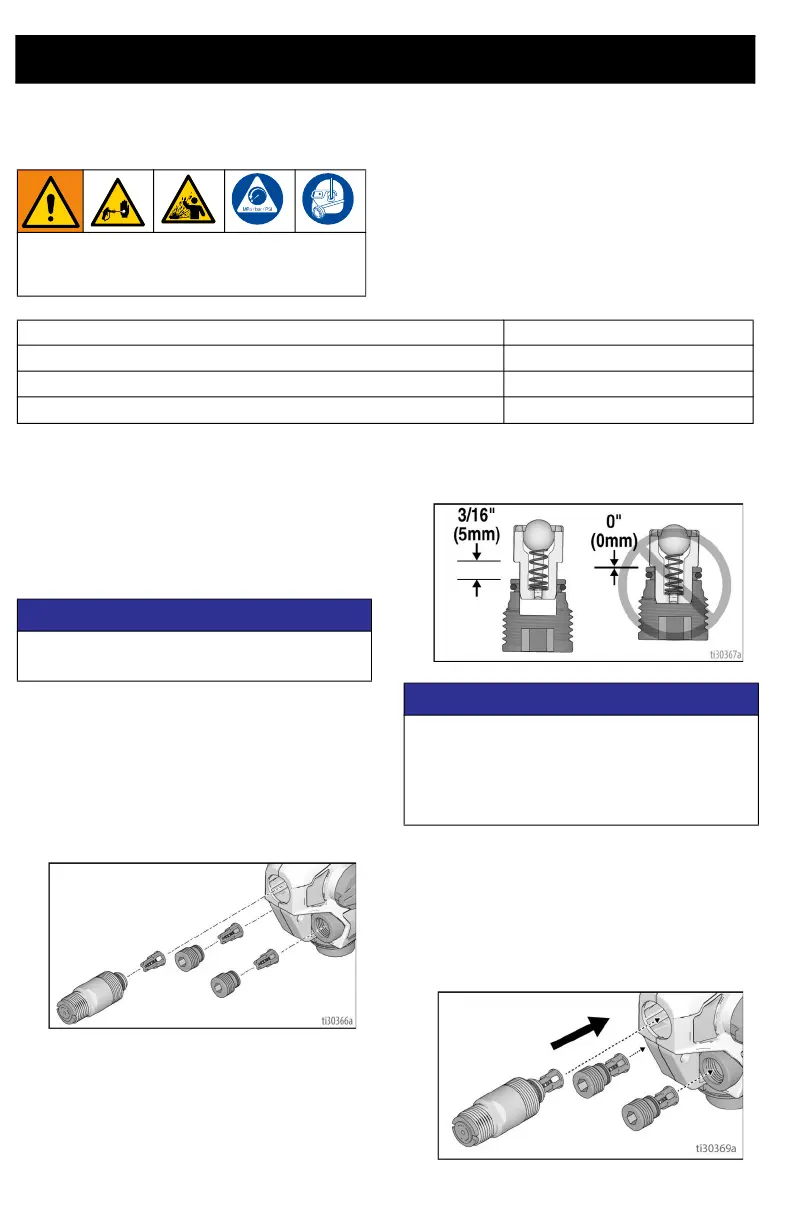

6. If outlet valve assembly was removed

from the valve plug, assemble as shown.

Leave a space between the end of the

plug or front valve and shoulder on the

outlet valve assembly.

a. Make certain o-rings are on the

valve plugs and front valve.

b. Install two pump plugs and front

valve. Install pump plugs with 8mm

or 5/16” Allen wrench. Torque

outlet valve and pump plugs, see

page 33 for torques.

Move sprayer to a well-ventilated area and

away from flammable or combustible

materials, including paints and solvents.

Activity Interval

Inspect Pump Filter. Daily or each time you spray

Inspect enclosure vents for blockage.

Daily or each time you spray

Inspect pump inlet holes located under Pump Filter for blockage.

Each time the sprayer is cleaned

NOTICE

Proper tools must be used to keep the

plugs/fittings from being stripped.

NOTICE

Do not push outlet valves all the way into

the valve plugs or front valve. If outlet

valves are pushed all the way into the valve

plugs or front valve the sprayer will spray

with reduced performance.

Loading...

Loading...