Troubleshooting

4.Checkfunctionalityofthedirectionalvalve(207).

a.Conrmthatthedirectionalvalvecable

isconnectedproperlyfromHCMport15

tothedirectionalvalvebody(207)and

isnotdamaged.Inspectwiringinside

thecoverofthedirectionalvalve.See

ElectricalSchematics,page102.

b.Duringoperation,thedirectionindicatorlights

onthedirectionalvalvebody(207)should

switchonbasedonthevalvethatisopen.

c.Turnonthemotorandstallthepumpsatthe

lowestpressuresetting(compensatorknob

turnedfullycounter-clockwise).Thepump

willtravelineithertheAorBdirectionuntil

thepressuresettingisreached.

d.Identifythesolenoidthatisoperatingby

viewingthedirectionindicatorlightsonthe

coverofthedirectionalvalve(207).Measure

voltageacrosstheassociatedterminalsto

determineifpropervoltageisreachingthe

valve(approximately200to240VAC).See

ElectricalSchematics,page102,andthe

tablebelow,toidentifytheproperterminals

tomeasureacross.

e.Triggereachproximityswitch(211)with

theshaftofascrewdriver,conrmingeach

solenoidwithinthedirectionalvalve(207)

operatesasdescribedintablebelow.

f.Ifoneorbothsidesarenotoperating

properly,accordingtothetable,rst

reconrmwiringtodirectionalvalve(207)

perElectricalSchematics,page102,then

replacedirectionalvalve(207).

For For

For

given given

given

pump pump

pump

movement movement

movement

direction: direction:

direction:

Pump Pump

Pump

driving driving

driving

left left

left

(toward (toward

(toward

park park

park

position) position)

position)

Pump Pump

Pump

driving driving

driving

right right

right

(away (away

(away

from from

from

park park

park

position) position)

position)

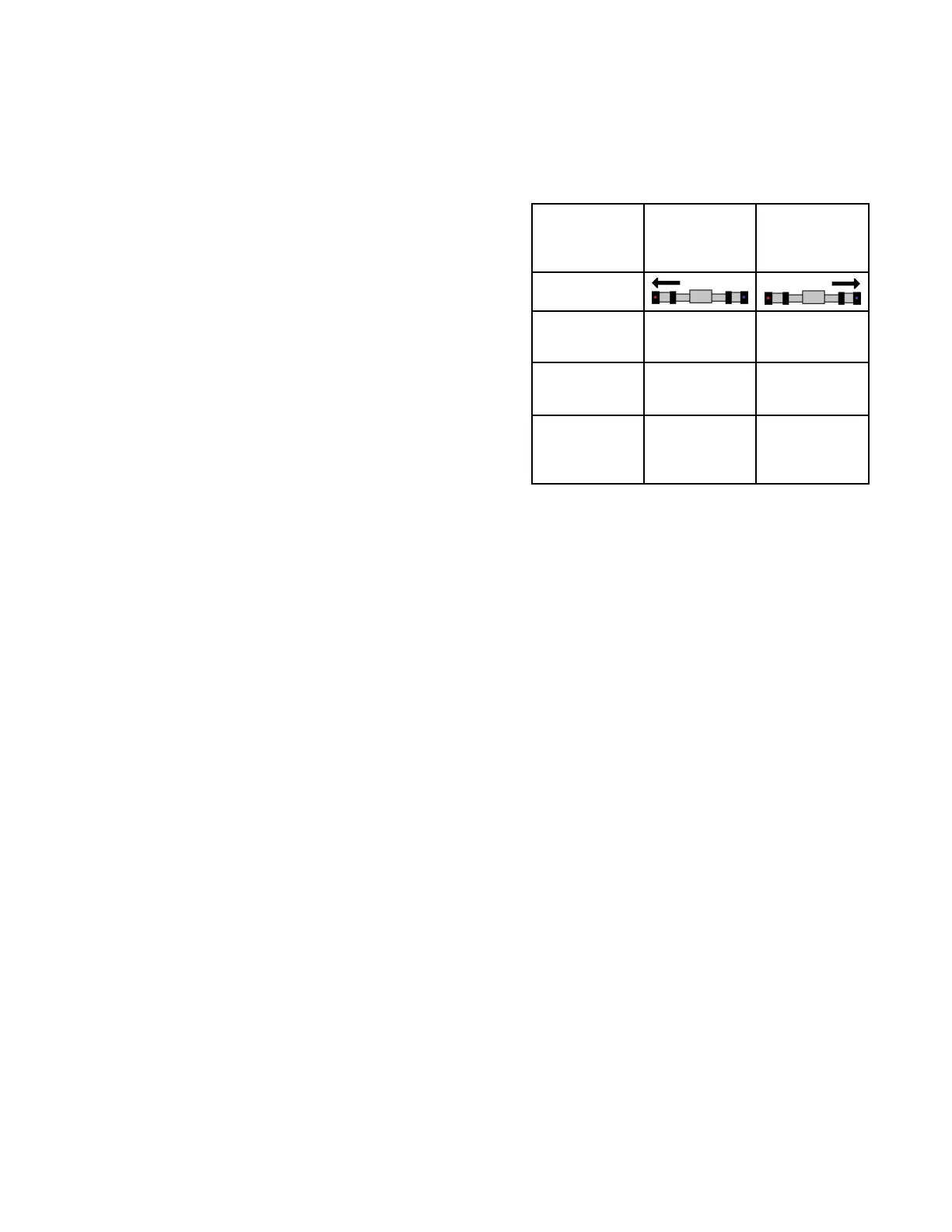

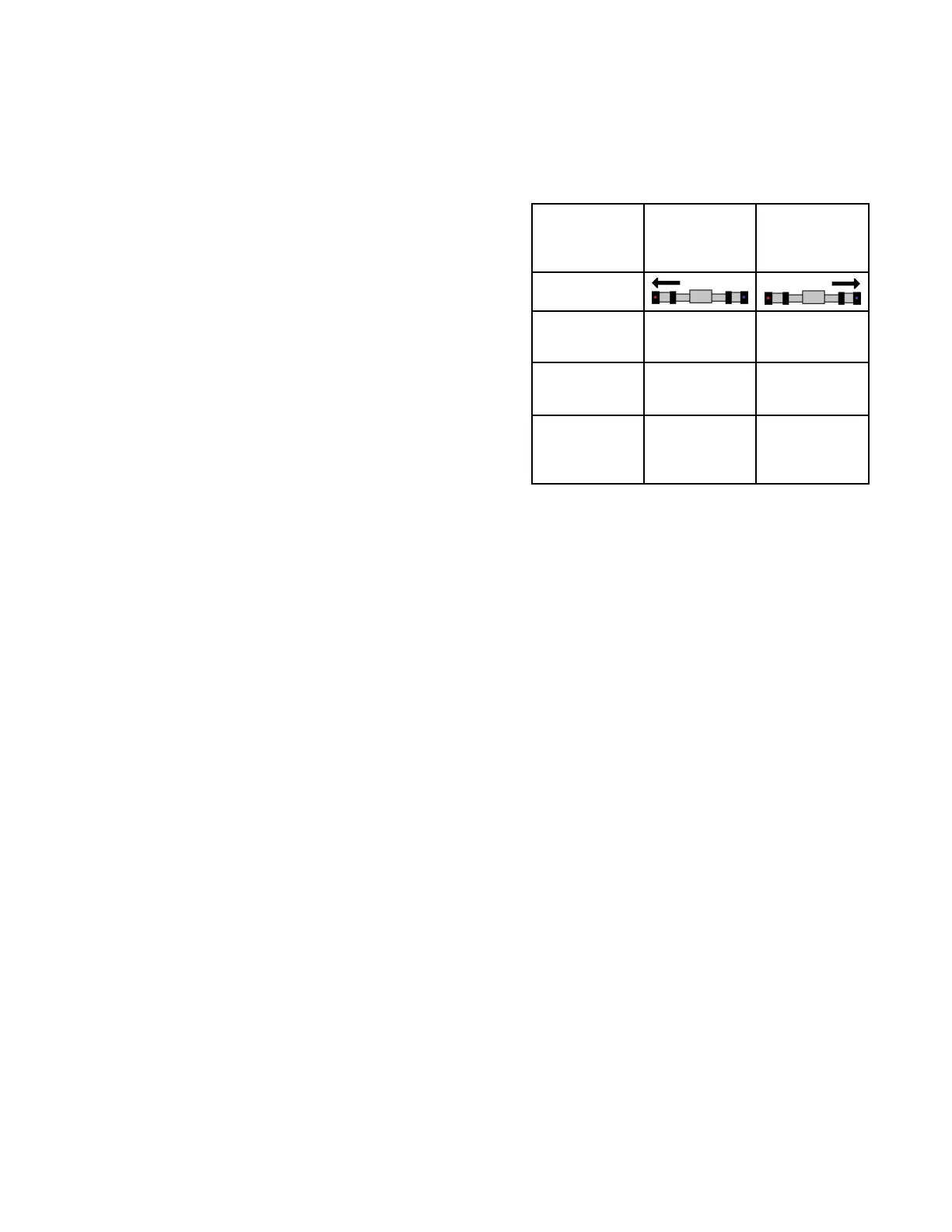

ADMindicates

Indicatorlight

ondirectional

valvecover

Leftarrow,

labeled“b”

Rightarrow,

labeled“a”

Lastproximity

switch

triggered

Rightside

proximity

switch

Leftside

proximity

switch

Terminalsin

directional

valve

energized

Terminals

associated

withredand

orangewires

Terminals

associated

withblackand

whitewires

NOTE: NOTE:

NOTE:

Fordiagnosticpurposes,itispossibleto

manuallyoverridethedirectionalvalvebyusing

asmallscrewdrivertodepressthebuttonin

thecenterofeitherdirectionalvalveendcap.

Depressingthebuttonintherightendcapshould

causethepumptotraveltotheright.Depressing

theleftbuttonshouldcausethepumptotravel

totheleft.

5.Ifyouhavedeterminedthatthecauseisnone

ofthepreviouspossiblecauses,checkfora

loosepistonpackingretainingbolt.Thiscauses

thepistontocontacttheinnerfaceofthepump

inletangebeforetheswitchingplateactivates

theproximityswitch.Shutdowntheunitand

disassembletheappropriatepumpforrepair.

Following Following

Following

step step

step

1, 1,

1,

if if

if

the the

the

proximity proximity

proximity

switch switch

switch

indicating indicating

indicating

lights lights

lights

do do

do

not not

not

light: light:

light:

6.Checkforlooseorfaultyproximityswitchcable

orconnections.Conrmtheconnectionstothe

proximityswitchesaretightandinternallyfree

fromoilandothercontaminates.

7.Swapthecablestotheproximityswitchestosee

iftheproblemfollowstheswitchorisinthecable.

Replaceeitherthefailedswitchorthecable.

8.ReplacetheHCM.SeeReplaceHCM,page70.

334946H

41

Loading...

Loading...