Spraying

Purge Purge

Purge

Air Air

Air

Procedure Procedure

Procedure

NOTE: NOTE:

NOTE:

Performthisprocedureanytimeairis

introducedintothesystem.

1.Relievepressure.See

PressureReliefProcedure,page62.

2.Installarecirculationkitorinstallbleedlines

betweentheoutletmanifoldrecirculationtting

andawastecontainer.

NOTICE NOTICE

NOTICE

Topreventequipmentdamage,donotcirculate

uidcontainingablowingagentwithout

consultingwithyourmaterialsupplierregarding

uidtemperaturelimits.

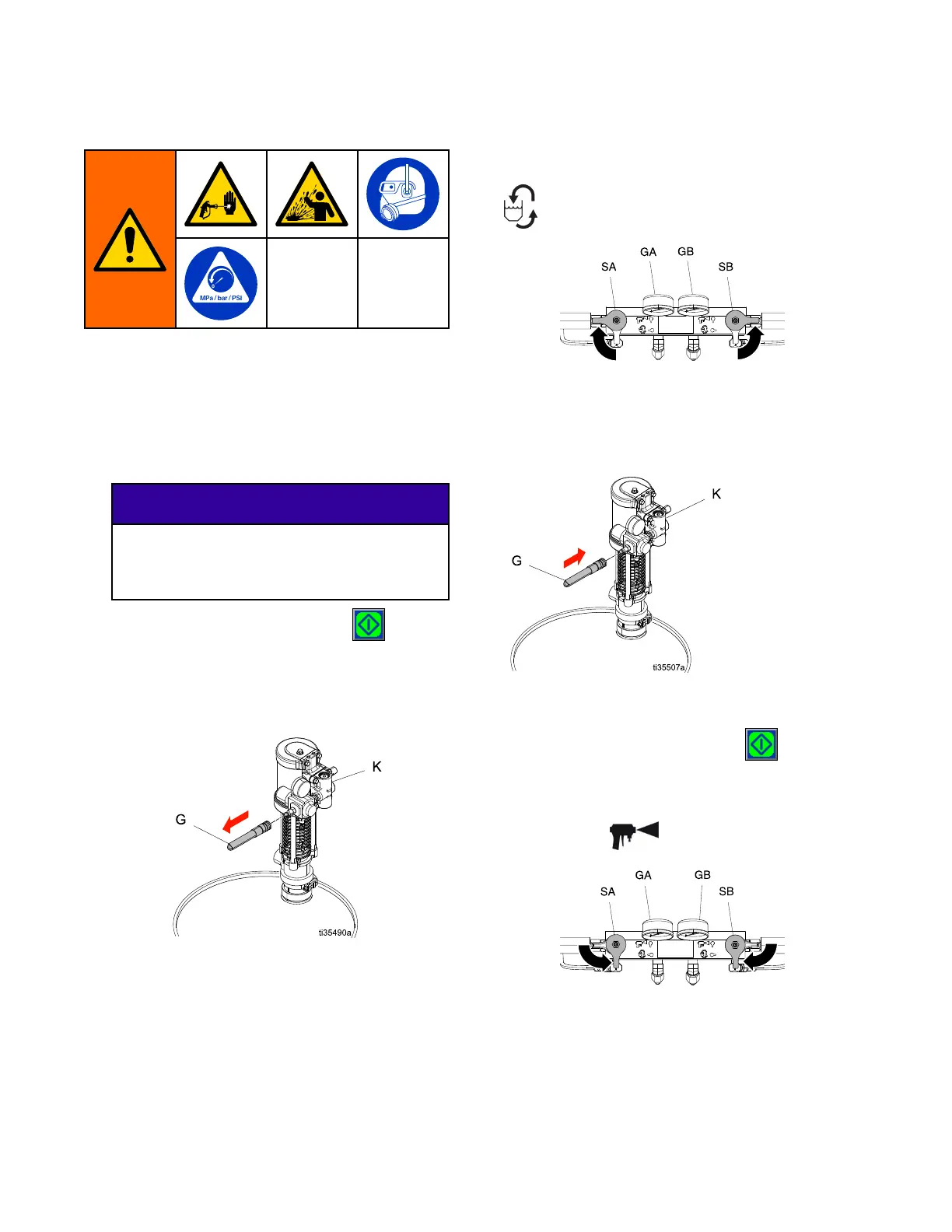

3.Presstheproportionerstopbuttontoturn

offthemotor.

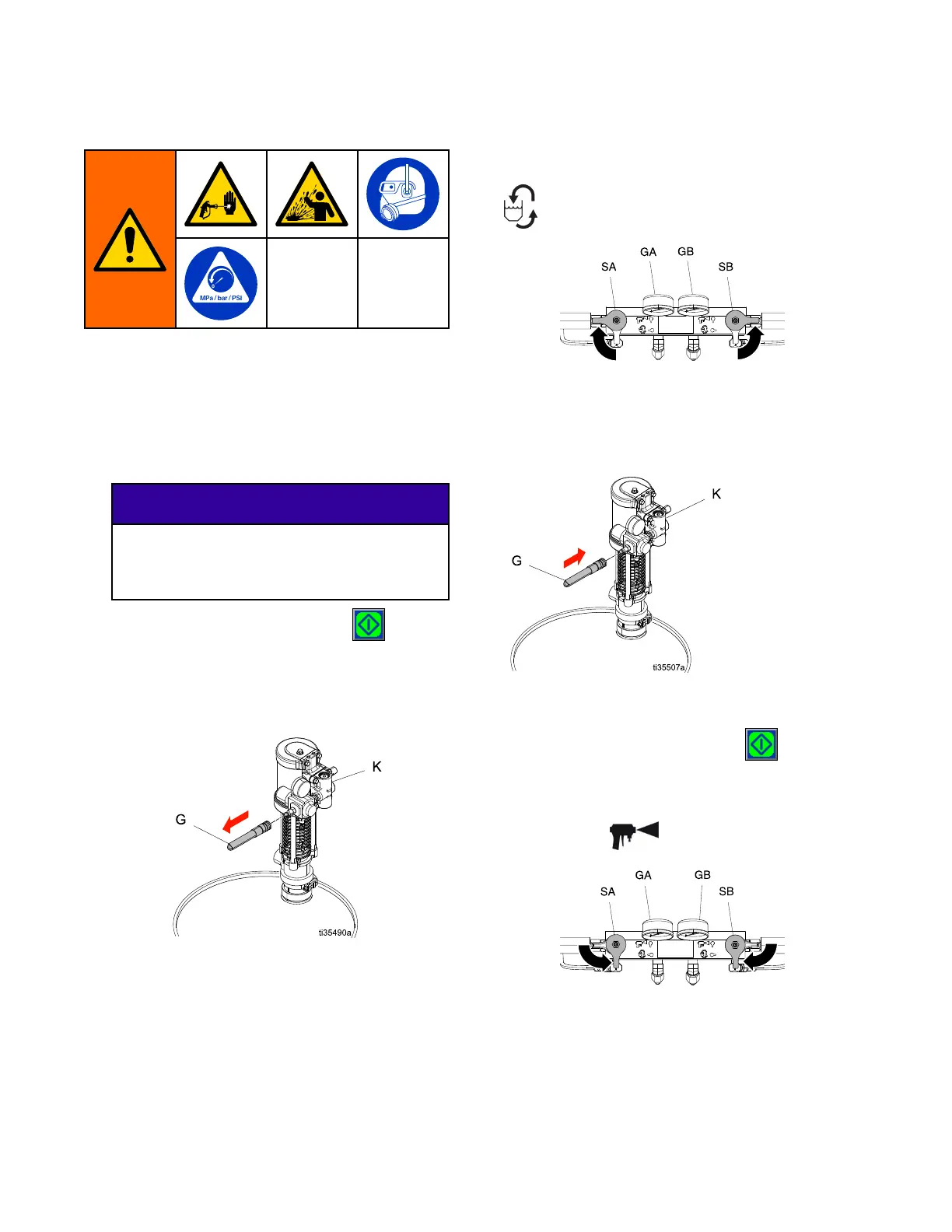

4.Torelieveairpressurefromthefeedpumps,

disconnecttheairsupplylines(G)fromthefeed

pumps(K).

5.SetthePRESSURERELIEF/SPRAYvalves

(SA,SB)toPRESSURERELIEF/CIRCULATION

.

6.Adjustthepressureinthefeedpumpairsupply

linesto100psi.

7.Topressurizethefeedpumps,connecttheair

supplylines(G)tothefeedpumps(K).

8.Adjusttheproportionerpressurecompensator

knobtolessthan500psi(3.4MPa,34Bar).

9.Presstheproportionerstartbutton

tostart

themotor.Run1gallon(3.8L)ofmaterial

throughthesystem.

10.SetthePRESSURERELIEF/SPRAYvalves(SA,

SB)toSPRAY

.

60 334945J

Loading...

Loading...