Important Isocyanate (ISO) Information

3A1570L 11

E01: High fluid temperature

Causes of E01 Errors

• Thermocouple A or B (361) senses a fluid tempera-

ture above 230°F (110°C).

• Fluid temperature sensor (FTS) senses a fluid tem-

perature above 230°F (110°C).

• Overtemperature switch (359) senses a fluid tem-

perature above 230°F (110°C) and opens. At 190°F

(87°C) the switch closes again.

• Thermocouple A or B (361) fails, is damaged, is not

touching the heater element (358), or has a poor

connection to the temperature control module.

• Overtemperature switch (359) fails in the open posi-

tion.

• The temperature control module fails to turn off any

heat zone.

• Zone power wires or thermocouples are switched

from one zone to another.

• Failed heater element where thermocouple is

installed.

• Loose wire

• Jumper wire covered in heat shrink in the wiring har-

ness near the single over temperature switch con-

nectors on the heater, is loose or incorrectly wired

Checks

Check which zone is displaying the E01 error.

1. Check that connector B is firmly plugged into tem-

perature control module (see F

IG. 6, page 27).

2. Clean and re-plug connections.

3. Check connections between the temperature con-

trol module and over-temperature switch (359), and

between temperature control module and thermo-

couples A and B (361) or FTS (21) [depending on

which zone is displaying E01]. See Table 2, page

27. Ensure that all wires are securely connected to

connector B.

4. Remove connector B from temperature control mod-

ule, and check continuity of overtemperature switch,

thermocouples A and B, or FTS by measuring resis-

tance across the pins on the plug end; see Table 1.

Before doing the following checks, note which zone (A,

B, FTS, or all) has high fluid temperature.

5. Verify fluid temperature, using an external tempera-

ture sensing device.

• If temperature is too high (sensor reading is

229°F [109°C] or above):

6. Check if thermocouples A and B are damaged, or

not contacting the heater element, page 31.

7. To test that temperature control module turns off

when equipment reaches temperature setpoint:

a. Set temperature setpoints far below displayed

temperature.

b. Turn zone on. If temperature rises steadily,

power module is failing.

c. Verify by swapping with another power module.

See Replacing Temperature Control Assem-

Troubleshooting this equipment requires access to

parts that may cause electric shock or other serious

injury if work is not performed properly. Have a quali-

fied electrician perform all electrical troubleshooting.

Be sure to shut off all power to the equipment before

repairing.

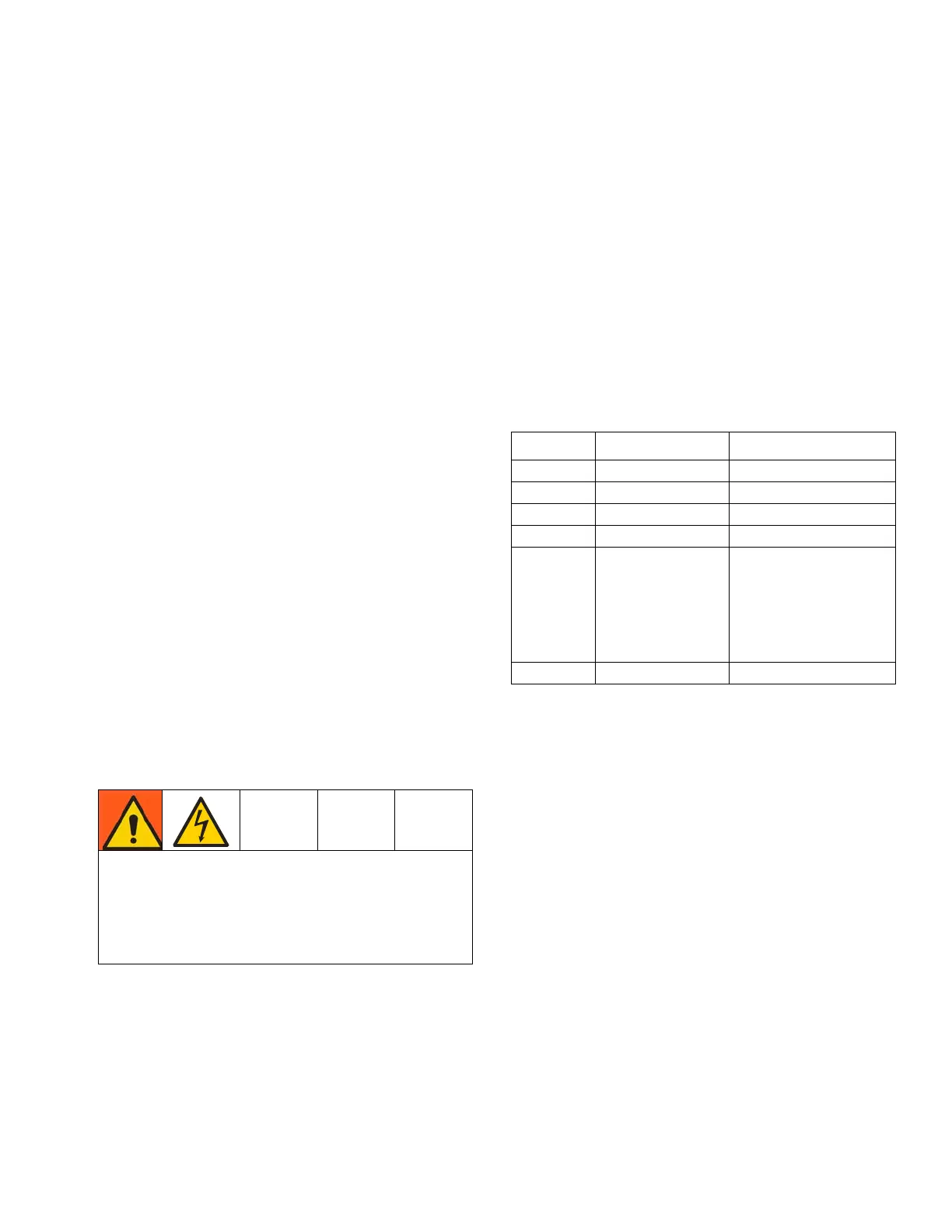

Table 1: Sensor Connector Continuity

Checks

Pins Description Reading

1 & 2 OT switch nearly 0 ohms

3 & 4 Jumpered nearly 0 ohms

5 & 6 Thermocouple A 4-6 ohms

8 & 9 Thermocouple B 4-6 ohms

11 & 12 FTS approximately 35

ohms per 50 ft (15.2

m) of hose, plus

approximately 10

ohms for FTS at 70°F

(21°C)

10 & 12 FTS open

Loading...

Loading...