10

Oil Storage &

Supply System

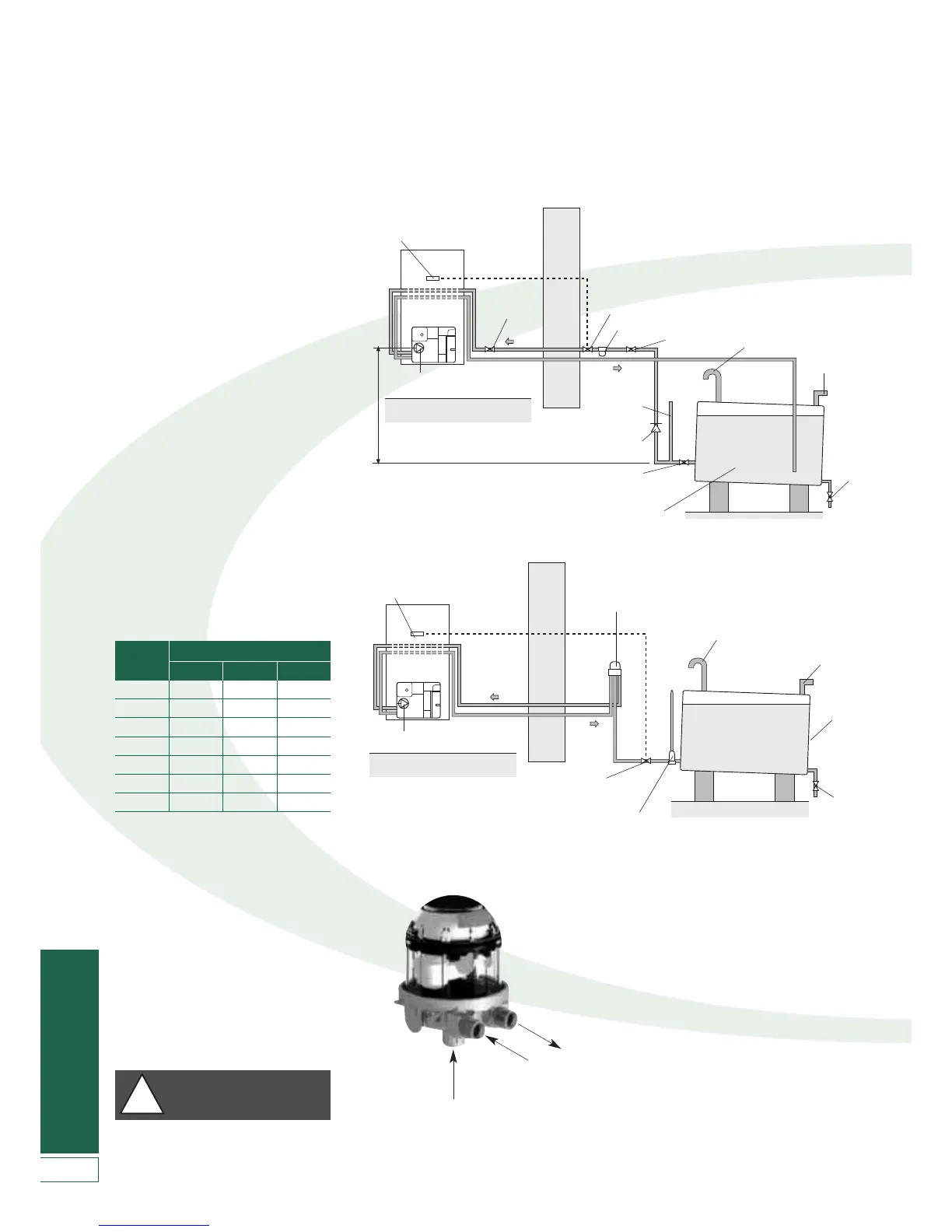

Two Pipe System - (See Figure 3-1)

With the storage tank outlet below the

burner, a two pipe system should be

used. The pipe runs should be as shown

in Figure 3-1. The return pipe should be at

the same level in the tank as the supply

pipe, both being 75 to 100mm above the

base of the tank. The pipe ends should

be a sufficient distance apart so as to

prevent any sediment disturbed by the

r

eturn entering the supply pipe.

Avoid the bottom of the tank being

more than 3m below the burner.

A non-return valve should be fitted in

the supply pipe together with the filter

and fire valve. A non-return valve should

be fitted in the return pipe if the top of

the tank is above the burner.

The pump vacuum should not exceed

0.4 bar.

Beyond this limit gas is released from

the oil.

For guidance on installation of top

outlet fuel tanks and suction oil supply

sizing, see OFTEC Technical Information

Book 3. Available from OFTEC.

Filter

F

ire valve

Fire valve

S

hut-off valve

Shut-off valve

Supply

Supply

Return

Return

A

Fire valve sensor

Fire valve sensor

L

evel Gauge

N

on return valve

Shut-off valve

S

ee section 4.4

V

ent pipe

Vent pipe

Fill pipe

Fill pipe

Fuel storage tank

Sludge

valve

Sludge

valve

H Pipe Length (m)

(m) ø 6mm ø 8mm ø 10mm

0.5 19 60 100

1 21 66 100

1.5 23 72 100

2 25 79 100

2.5 27 85 100

3 29 91 100

3.5 31 98 100

Figure 3-1: Two pipe system

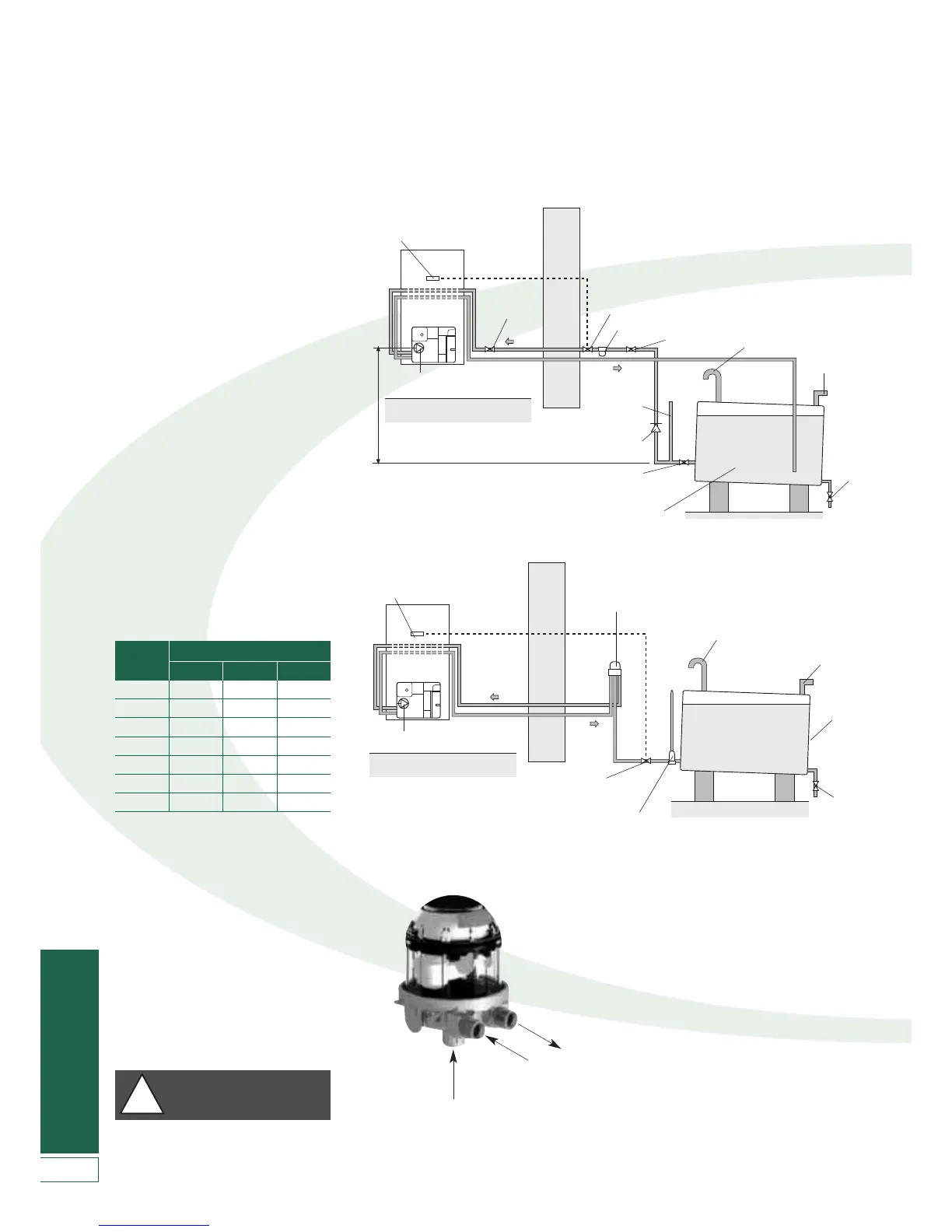

Tiger Loop System -

(See Figures 3-2 and 3-3)

When the storage tank outlet is below

the burner, an alternative to a two pipe

system can be achieved using a

'Tiger Loop' type oil de-aerator.

This effectively removes the air from

the oil supply on a single pipe lift.

The de-aerator is connected close to the

boiler as a two pipe system (omitting the

non-return valve) as shown in Figure 3-2.

Refer to the manufacturers instructions

supplied with the de-aerator.

The de-aerator must be mounted

vertically, Figure 3-2.

To prevent any possibility of fuel

fumes entering the building, the

de-aerator must be fitted outside in

accordance with BS 5410:1:1997.

!

WARNING

Tankmaster

Fuel

storage

tank

De-aeration device e.g

Tiger Loop see Figure 3-3

See section 4.4

Figure 3-2: De-aeration device system

Figure 3-3: Tiger loop de-aeration device

To burner

From burner

From tank

Loading...

Loading...