Boiler Servicing

41

10. Replace the front cleaning door,

ensuring the seal is in good

condition and secure it in position

with the nuts and washers

previously removed. Tighten to form

a seal.

11. Remove the condensate trap and

check that it is not blocked and is

operating correctly, i.e. the float is free

to move. Clean the trap and float as

required. Refer to Section 6.8.

12. Check that the boiler condensate

outlet is unobstructed. Clean if

necessary.

!

NOTE

The condensate trap and condensate

outlet must be checked on every

service and cleaned as necessary.

11.4 Cleaning the Burner

The procedure is:

1. Combustion head - Loosen the two

screws securing the combustion

head and withdraw the head.

2. Clean the combustion head.

3. Inspect the ignition electrodes -

Loosen the electrode clamp screw

and withdraw the electrode

assembly. Wipe clean and check for

any cracks in the ceramic insulation.

Replace if necessary.

4. Nozzle - The nozzle should be

replaced on an annual service -

Check that the nozzle size and type

are correct, refer to table in Section

3.3 and boiler data label.

5. Do not attempt to clean the nozzle.

6. Remove the nozzle using a good

fitting spanner (16mm).

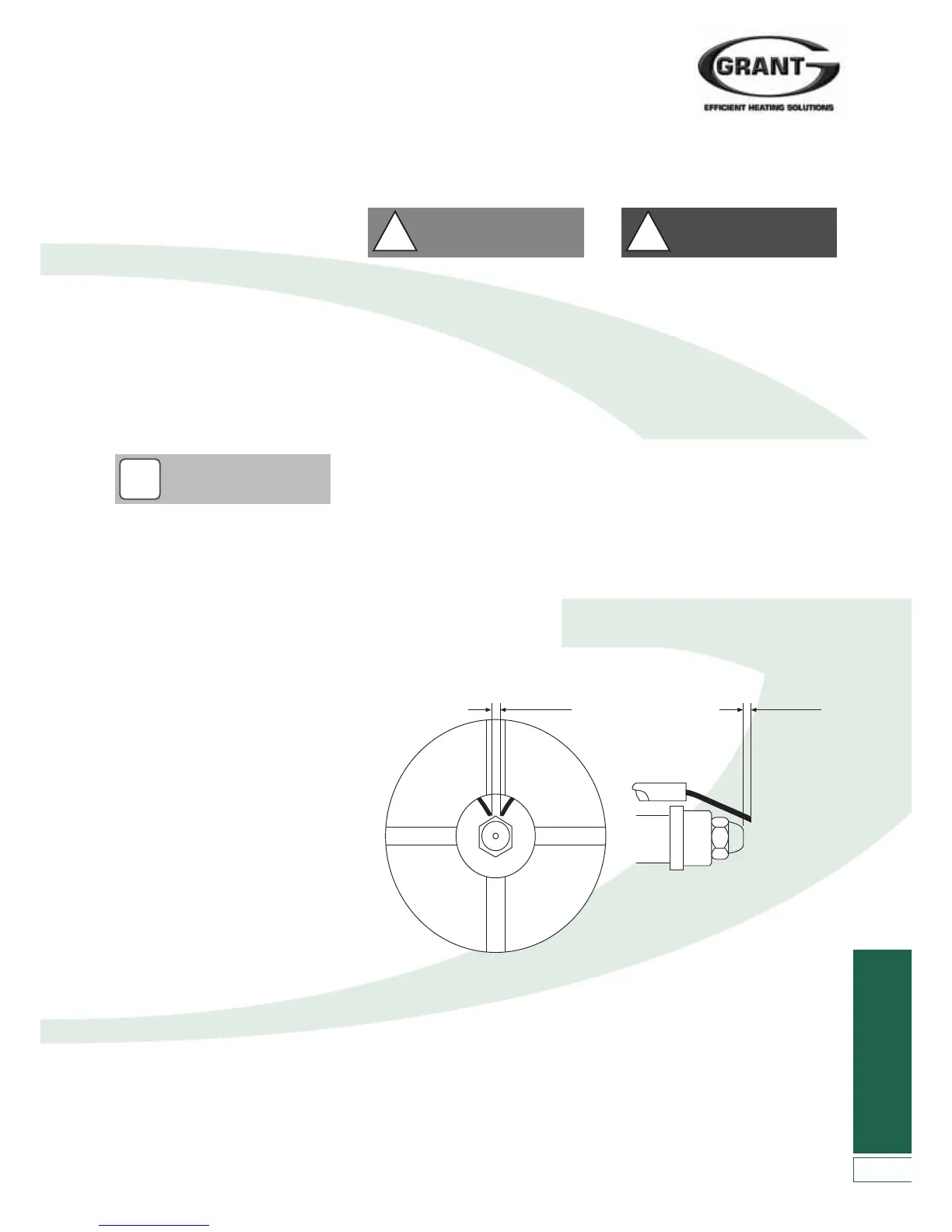

Figure 11-2: Electrodes showing setting

4mm

3mm

!

CAUTION

The use of an ill-fitting spanner will

d

amage the nozzle and could lead to

an incorrect flame pattern.

7. Always check the electrode settings

after replacing the nozzle, see Figure

11-2.

8. Re-connect the HT leads to the

electrodes and refit the combustion

head.

All models

Photocell - The photocell is a push-fit in

the burner body. Carefully pull out the

photocell to clean.

Burner fan – Remove the air intake from

the burner. Check, inspect and clean

the fan as required. Replace the cover.

Pump filter - Remove the four screws

securing the pump end cover. Remove

the filter and wash in kerosene. Replace

the filter and end cover, ensure the 'O'

ring is in position.

Re-assemble in reverse order.

To ensure safe and efficient operation

o

f the boiler it is important that re-

commissioning is carried out,

especially combustion checks (CO

2

level, flue gas temperature and

smoke number) after the boiler has

been serviced.

Refer to the Commissioning

instructions in Section 10.

!

WARNING

Loading...

Loading...