Boiler Installation

Information

15

Figure 4-8: Installing the back panel

Figure 4-9: Fixing the back panel

7. Locate the mounting bracket on to

the back panel, aligning the four

holes in the bracket with those in

the back panel. Ensure that the

mounting ‘hooks’ are pointing

upwards and secure using the

f

ixings supplied by Grant UK.

8. Lift the boiler shell and hang it on the

mounting bracket – ensuring that the

mounting plates on either side of the

shell are fully located in the vertical

slot of both mounting hooks.

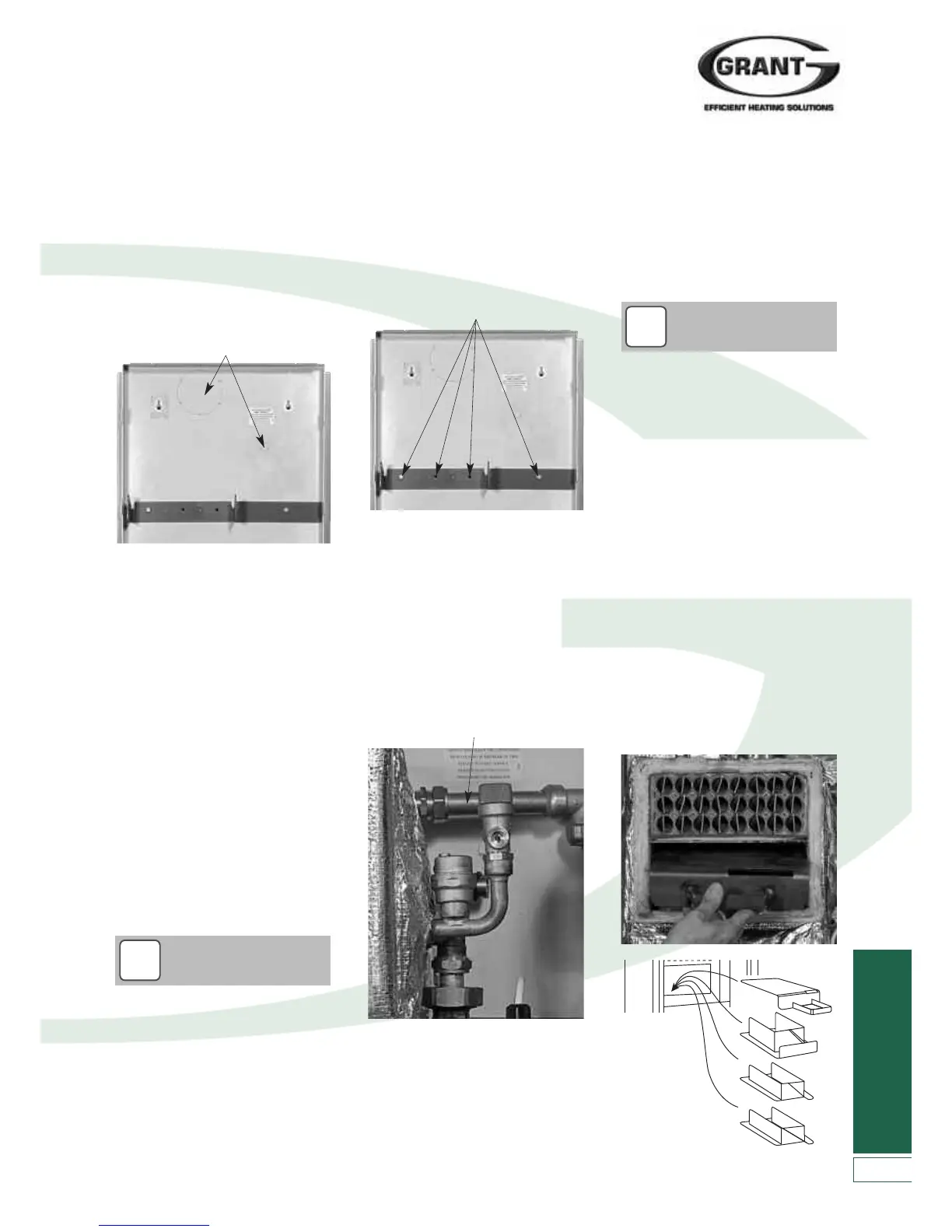

9. Re-fit the return pipe to top right

hand connection on boiler shell.

Pass return pipe from system

through hole in back panel (either at

top or bottom of panel, as required)

and connect to boiler return pipe.

11. Non-system model – Re-fit flow pipe

to compression connection on boiler

shell. Pass flow pipe from system

through hole in back panel (either at

top or bottom of panel, as required)

and connect to boiler flow pipe.

10. System model only - Re-fit pump

complete with flow pipe to upper

pump union on boiler shell. Ensure

that rubber pump union washer is

fitted. Pass flow pipe from system

through hole in back panel (either at

top or bottom of panel, as required)

and connect to boiler flow pipe.

Figure 4-10: Re-fitting flow & return pipe

Figure 4-11: Re-fitting baffles into

boiler shell

4

.5 Installing the Boiler

You are now ready to install the boiler.

The procedure is as follows:

1. If a back outlet flue system is to be

used, remove the large circular flue

knockout from back panel. If the rear

outlet PRV discharge is to be used,

remove the knockout from the back

panel (as shown in the figure below.

If side outlet flue is to be used (to

either left or right) then mark position

as it may be necessary to cut flue hole

BEFORE installing boiler on to wall.

6. Remove the back panel from the

wall. Drill the holes for the mounting

bracket fixings and fit the wall plugs

provided. Drill all other necessary

holes. If required, core drill the wall

for a back outlet flue and drill a hole

for the PRV discharge pipe.

Re-mount the back panel on the

two keyholes slots.

!

NOTE

I

t is recommended that the system

flow and return pipes are connected to

the boiler at this point in the

installation. Two 22mm isolating valves

are supplied for use with sealed

system models only. These must not

be used on an open vented system.

These boiler isolating valves should

be located adjacent to the boiler in a

convenient position.

12. Re-fit burner. First remove burner

securing nut, locate burner head

into hole in burner flange/boiler shell

and locate mounting screw through

hole on top of burner. Re-fit nut and

tighten to secure burner in place.

Connect flexible oil lines from oil

supply pipework to burner. It is

recommended that the copper oil

lines are installed at this stage while

the side panels are not in place.

13. Re-fit baffles into boiler shell –

ensuring they are in the correct

order (check marking on each baffle)

as shown below

!

NOTE

1

2

3

4

2. Locate and hold the back panel in the

required position on the wall. Check it

is level using a spirit level on the top

flange. Mark position of the holes for

the two keyhole slots. Remove the

back panel from the wall.

3. Drill and fit wall fixing plugs (not

supplied) in the two holes. Fit suitable

screws and mount the back panel on

the wall using the two keyhole slots.

Check again that the back panel is

level before proceeding.

4. Mark the position of the four

mounting bracket fixings on to the

wall from the back panel. Also mark

the positions of the flow and return

pipes, the cold mains (for filling

loop), the electrical power supply,

and the condensate discharge pipe.

5. If using a back outlet flue and/or

rear PRV outlet is to be used, also

mark these holes on to the wall.

Loading...

Loading...