G36

Oxygen Analyzer

Version 2.11 - March 2022 15

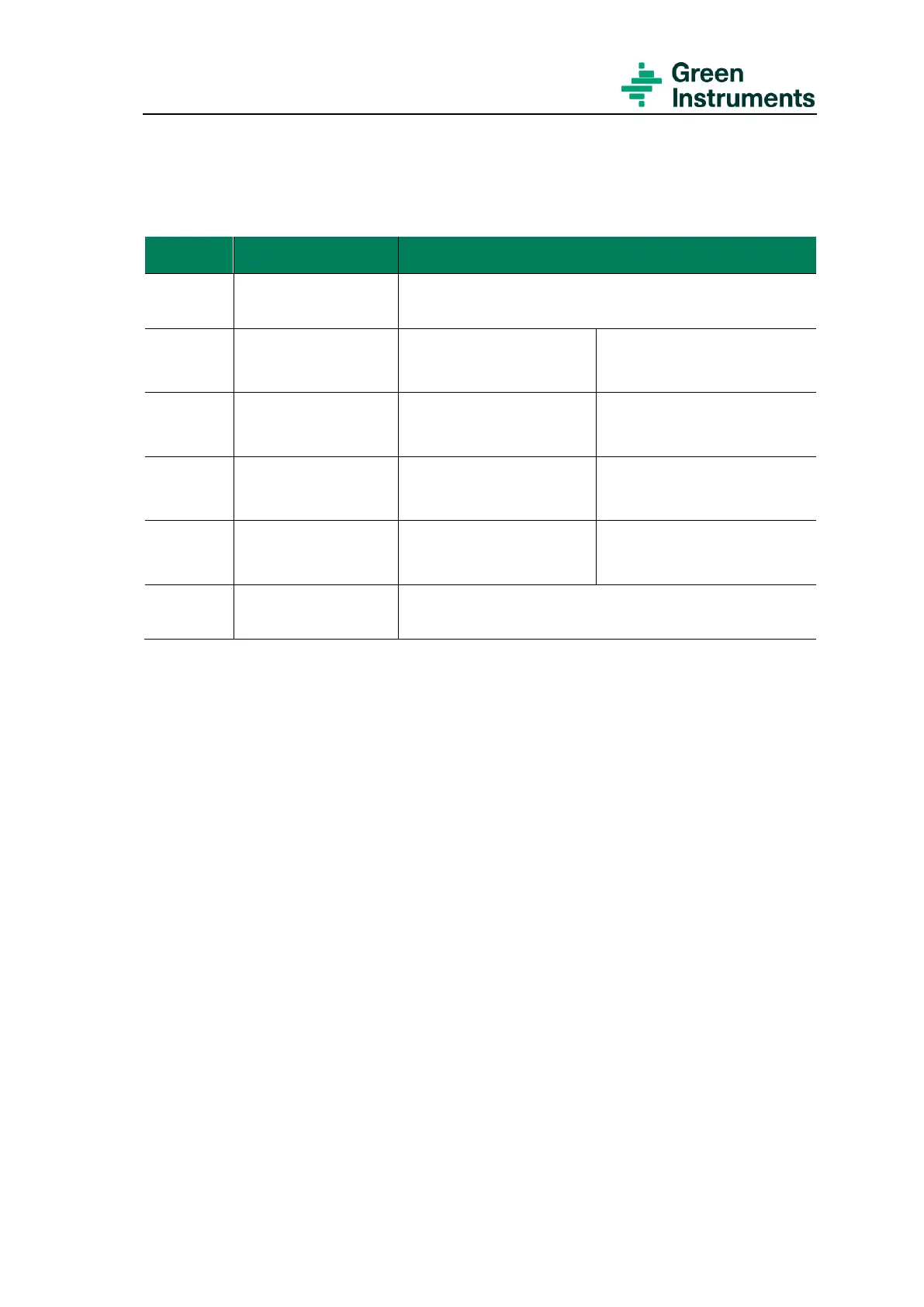

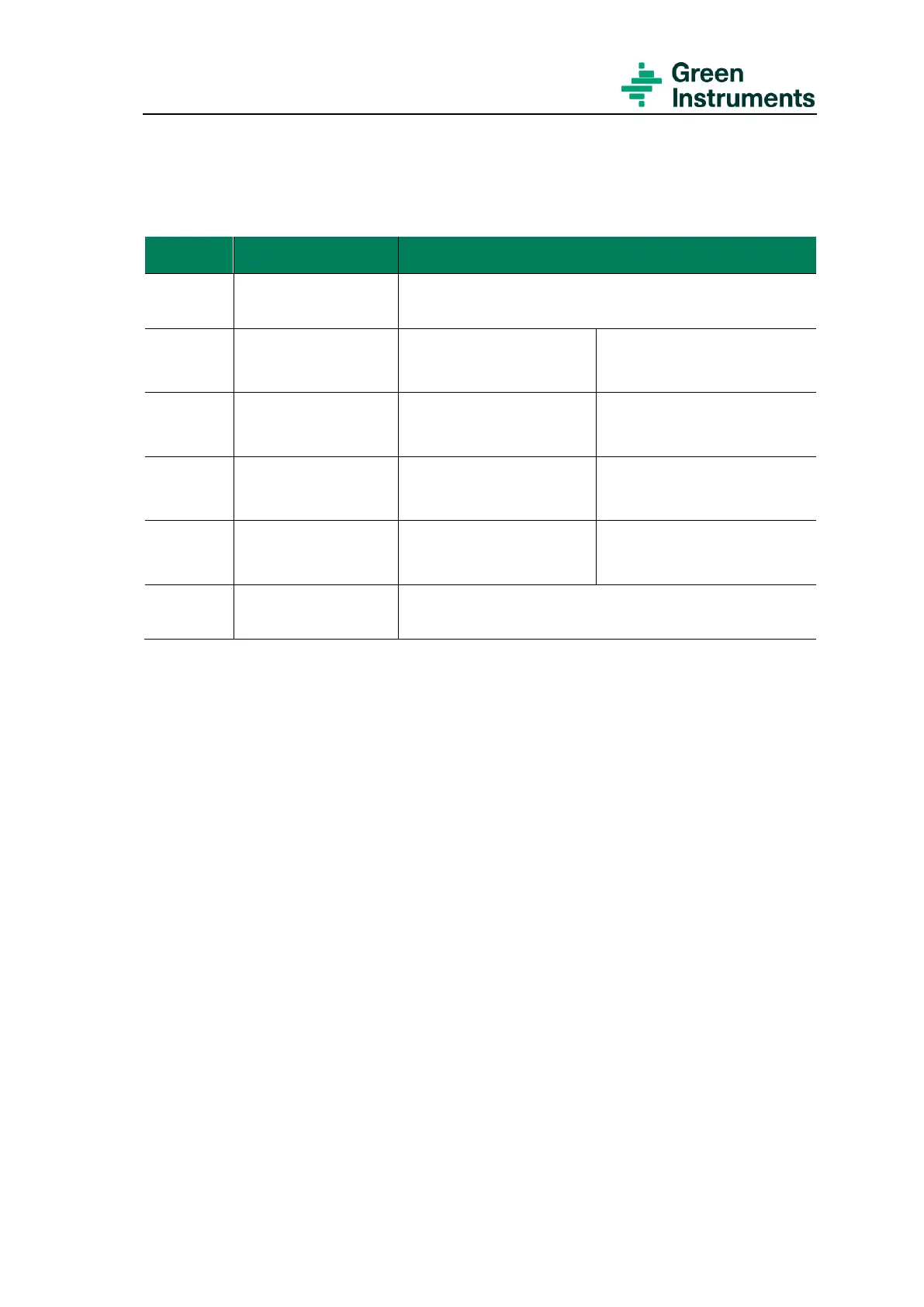

For the Stack Gas Oxygen Analyzer and the EGR Oxygen Analyzer relay functions and

connections are as follows:

Alarms

The values for three O2 level alarms (Low, High, and High-High) can be set following

instruction in section 7.2.

The system failure alarm includes a sensor alarm and alarm for open loop of the analog

outputs. If the G36 Oxygen Analyzer is configured with a digital flow switch, the system

failure alarm will also include the flow alarm.

Normally energized

Normally energized means that the relay is energized in the alarm free condition during

operation. The relay will be de-energized when there is an alarm or when the supply volt-

age disappears from the analyzer. Thus, the normally energized relays will give a fault

signal in the event of failure of power to the analyzer.

Normally de-energized

Normally de-energized means that the relay is de-energized in the normal operating con-

dition. For the Inert Gas Oxygen Analyzer, relay 4 (normally de-energized) will be ener-

gized in span calibration condition. For the Stack Gas Oxygen Analyzer or the EGR Ox-

ygen Analyzer, relay 3 or 4 respectively will be energized when the analyzer is back-

flushing or auto calibrating.

Loading...

Loading...