Greenlee Textron / Subsidiary of Textron Inc.

8

4455 Boeing Dr., Rockford, IL 61109-2988 815/397-7070

555 Electric Bender

1/2" - 2" Rigid Conduit, Schedule 40 Pipe

and 1/2" - 1-1/4" EMT

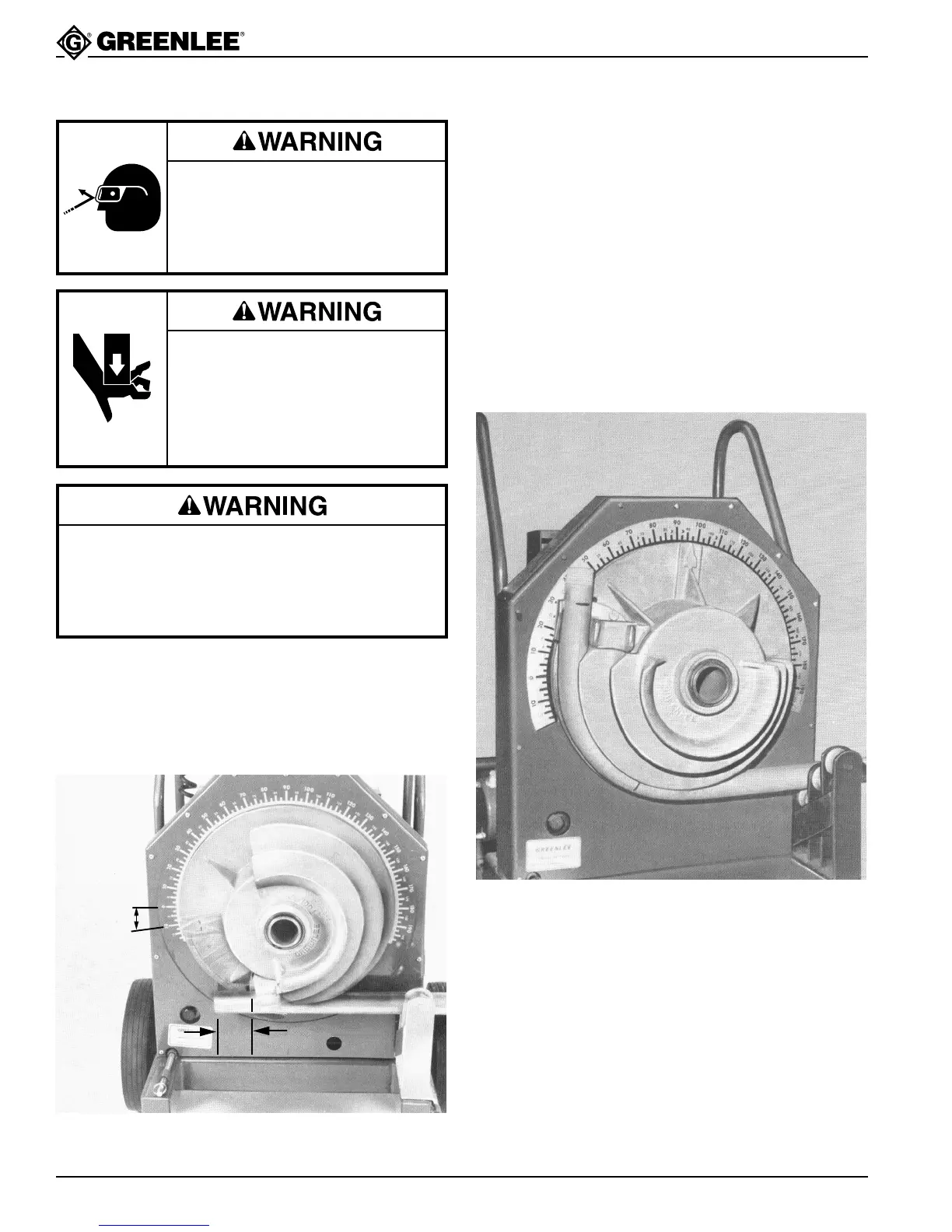

Refer to Setup for mounting selected shoe and support

unit. Mark pipe to desired stub-up length. Note 2" min.

dimension is required as shown in Fig. 4. Other stub-up

Figure 4

Bending Instructions

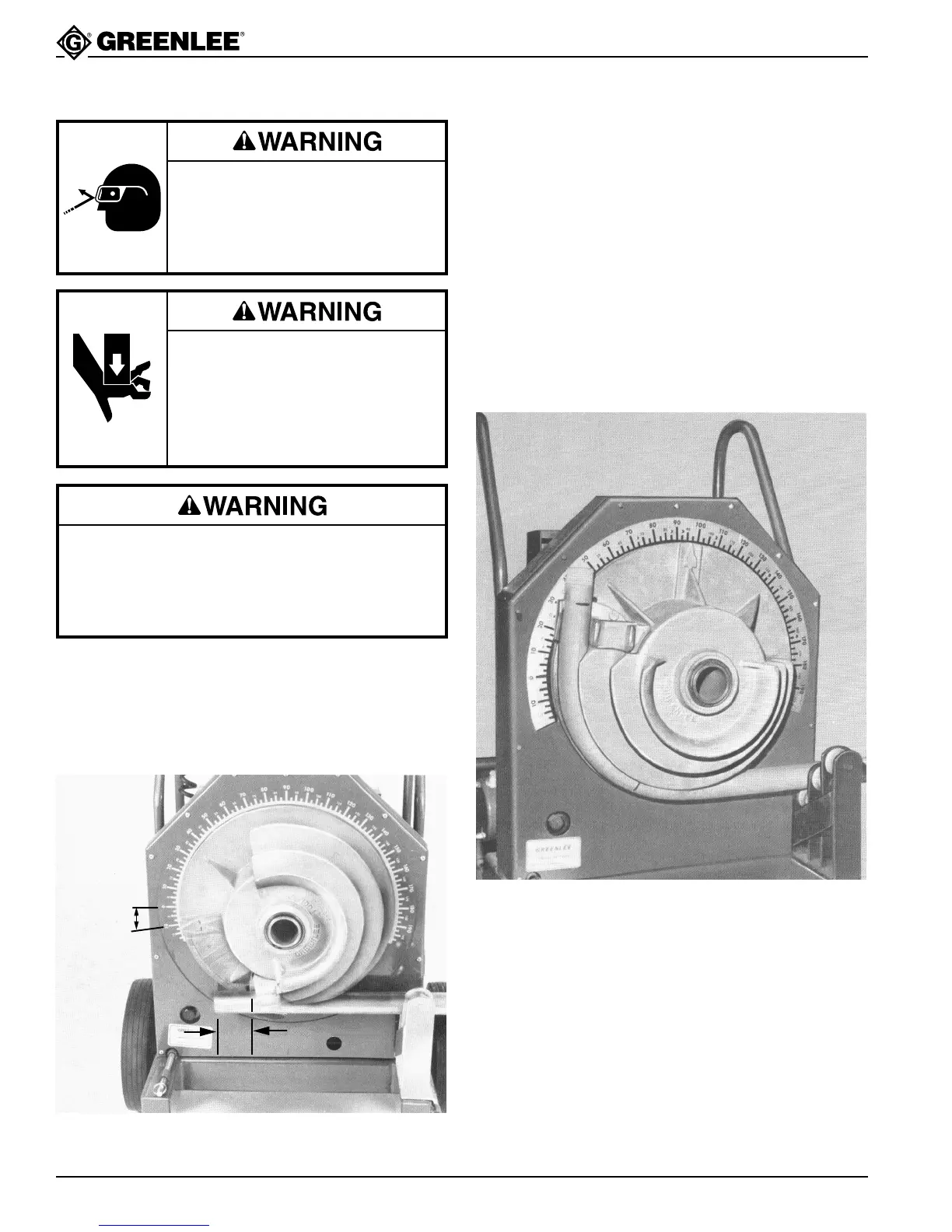

Figure 5

To release the pipe or conduit push the control switch

to the UNLOAD position. Allow shoe to rotate, drop

the unit support (see Fig. 6) and remove conduit

(see Figs. 7 & 8).

Wear eye protection when operating

or servicing this tool.

Failure to wear eye protection can

result in serious eye injury from

flying debris.

Pinch points:

Keep hands away from bending

shoe, rollers and conduit when

bender is in use.

Failure to observe this warning can

result in severe injury or death.

Do not operate the bender while wearing loose

clothing. Loose clothing can get caught in moving

parts.

Failure to observe this warning can result in severe

injury or death.

dimensions can be found in charts on pages 16-25 of

this manual or on the bender decals. At this point, make

sure the shoe is rotated to 5° to 10° before the 0°

setting. After marking the pipe or conduit, place it into

the bender unit as shown in Fig. 4. This requires sliding

the pipe or conduit over the correct size support unit

through the shoe groove and into the hook. Position

Mark 2 at front edge of hook (see Fig. 4).

Push the control switch to the BEND position; when the

pointer on the shoe reaches the required bend angle

(Chart B), release the control switch and the bender will

stop (see Fig. 5). Due to springback in pipe/conduit

some overbending is necessary to accomplish desired

bend angle. For this reason Chart B and/or decal on

bender show the required pointer position for desired

bend angle.

5 to 10°

2" minimum

Loading...

Loading...