910FS Splicer

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

40

High Splice Loss Cause and Remedy (cont’d)

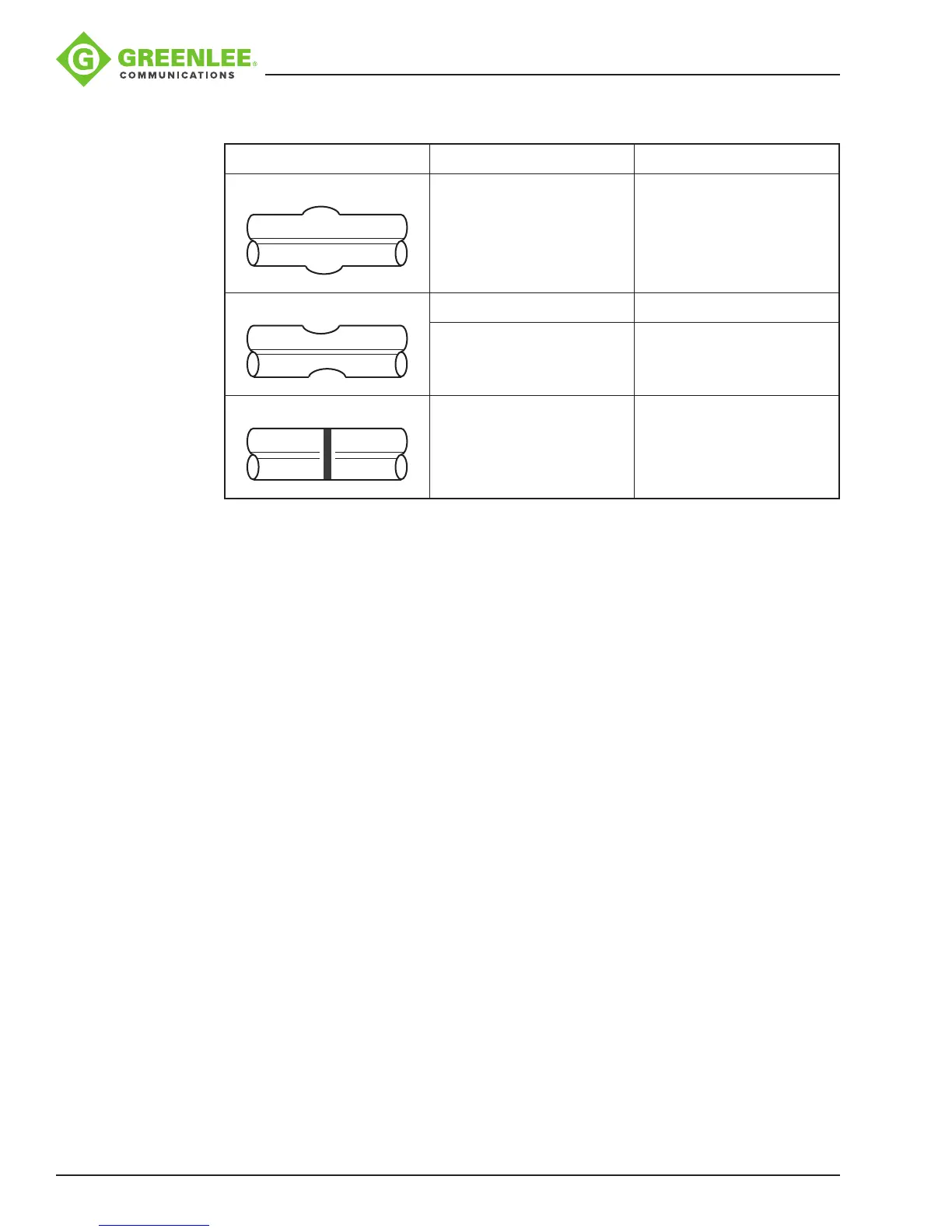

Symptom Cause Remedy

Fat Fiber stufng too much. Decrease “Overlap”

and perform “Motor

Calibration”.

Thin Arc power not adequate. Perform “Arc Calibration”.

Some arc parameters not

adequate.

Adjust “Prefuse Power”,

“Prefuse Time”, or

“Overlap”.

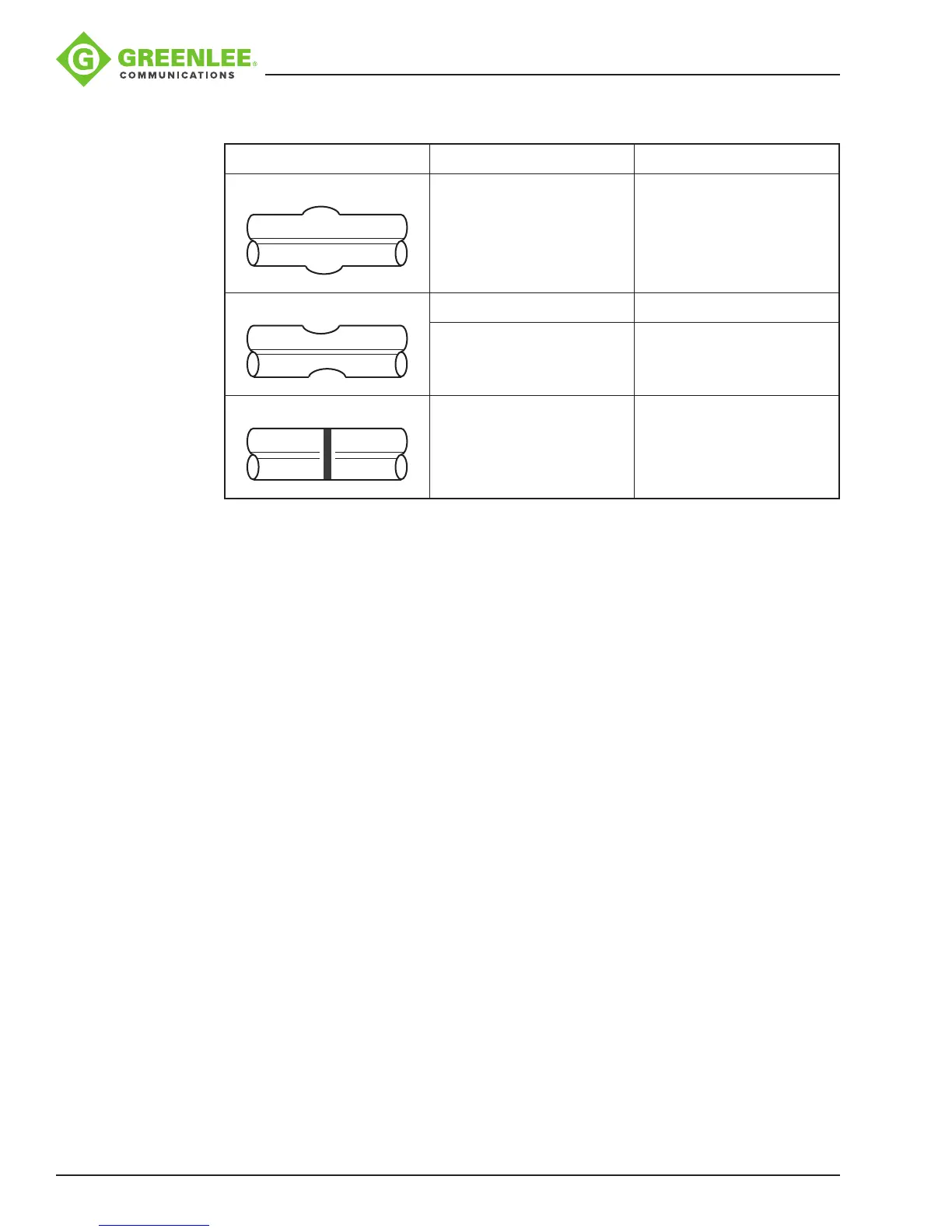

Line Some arc parameters not

adequate.

Adjust “Prefuse Power”,

“Prefuse Time”, or

“Overlap”.

Note: A vertical line sometimes appears at the spice point when MM bers or dissimilar

bers (different diameters) are spliced. This does not affect splice quality, such as splice

loss or tensile strength.

Note: If the user is getting high splice losses, make sure that the 910FS is not in Splice

Mode #10, which is used to make attenuator splices.

Cleaver

If the cleaver does not cleave, make sure that the 250 micron acrylic coating is being

removed during the ber stripping process.

Loading...

Loading...