910FS Splicer

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

39

Section 5. Troubleshooting

High Splice Loss Cause and Remedy

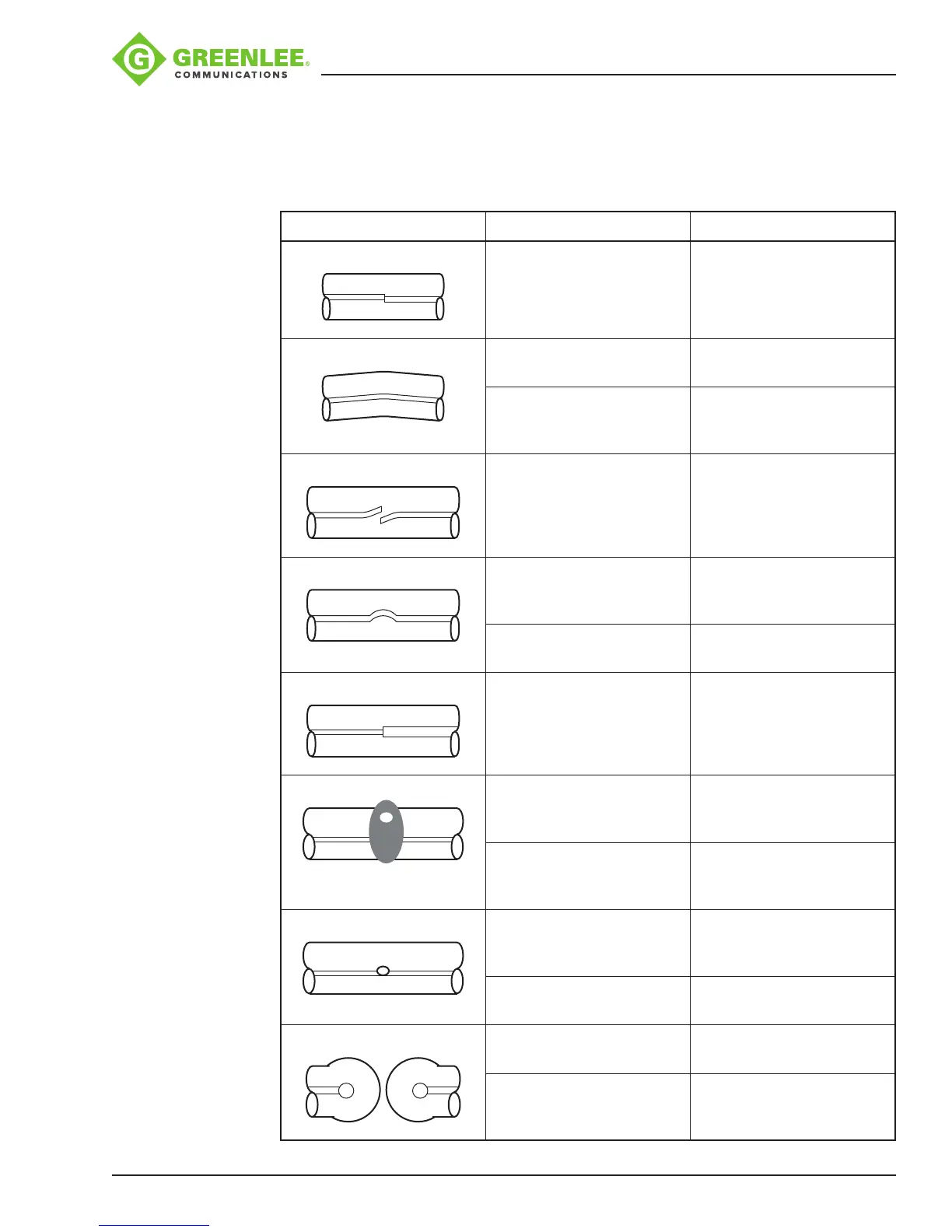

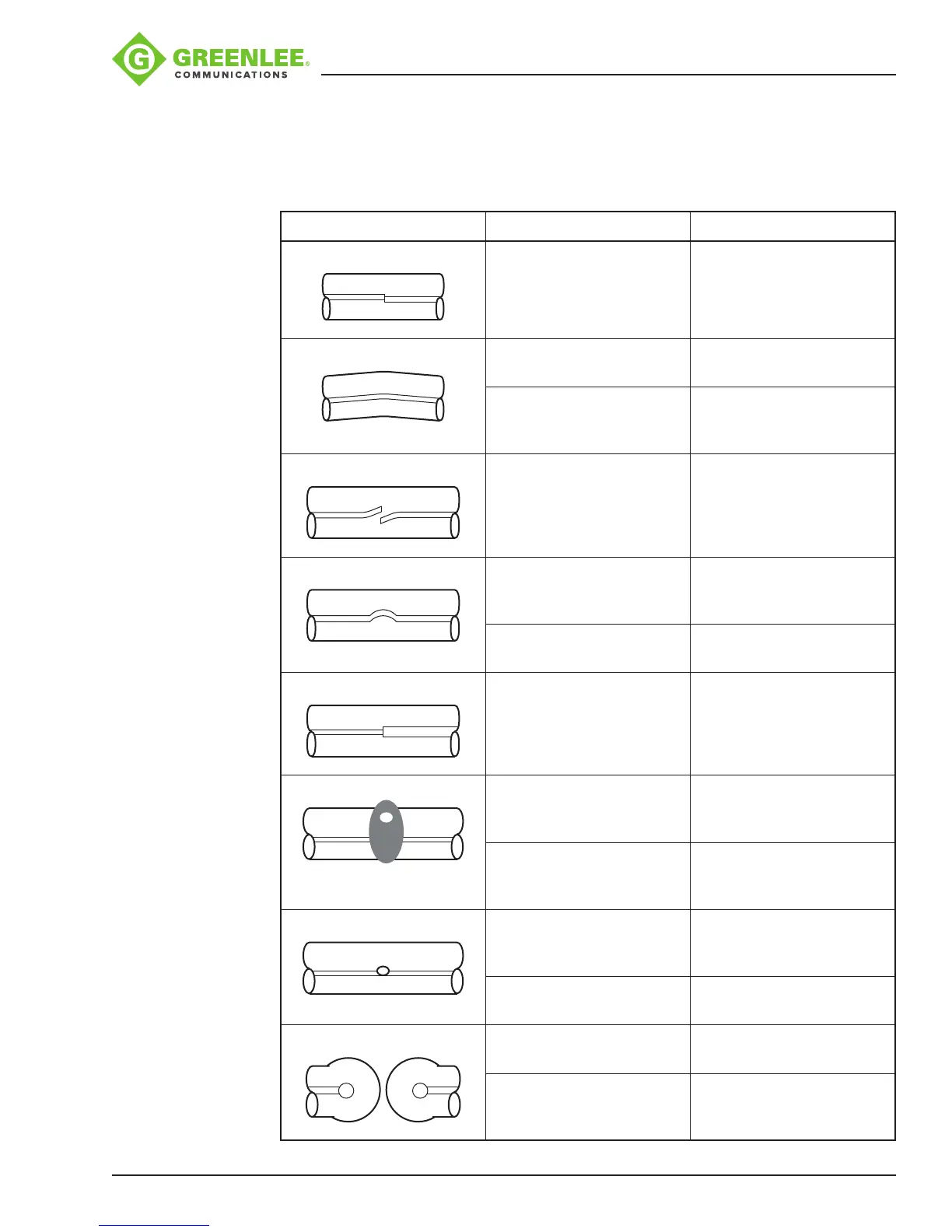

Symptom Cause Remedy

Core axial offset Dust on V-groove or ber

clamp chip.

Clean V-groove and ber

clamp chip.

Core angle Dust on V-groove or ber

clamp chip damaged.

Clean V-groove and ber.

Check clamp chip.

Bad ber end-face quality. Check if ber cleaver

is clean and in good

condition.

Core step Dust on V-groove or ber

clamp chip.

Clean V-groove and ber

clamp chip.

Core curve Bad ber end-face quality. Check if ber cleaver

is clean and in good

condition.

Prefuse power too low, or

prefuse time too short.

Increase “Prefuse Power”

and/or “Prefuse Time”.

MFD mismatch Arc power too low. Increase “Arc Power” and/

or “Arc Time”.

Combustion Bad ber end-face quality. Check if ber cleaver

is clean and in good

condition.

Dust still present after

cleaning ber or cleaning

arc.

Clean ber thoroughly and/

or increase “Cleaning Arc

Time.”

Bubbles Bad ber end-face quality. Check if ber cleaver

is clean and in good

condition.

Prefuse power too low, or

prefuse time too short.

Increase “Prefuse Power”

and/or “Prefuse Time”.

Separation Fiber stufng too small. Perform “Motor

Calibration”.

Prefuse power too high, or

prefuse time too long.

Decrease “Prefuse Power”

and/or “Prefuse Time”.

continued on next page

Loading...

Loading...