910FS Splicer

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

41

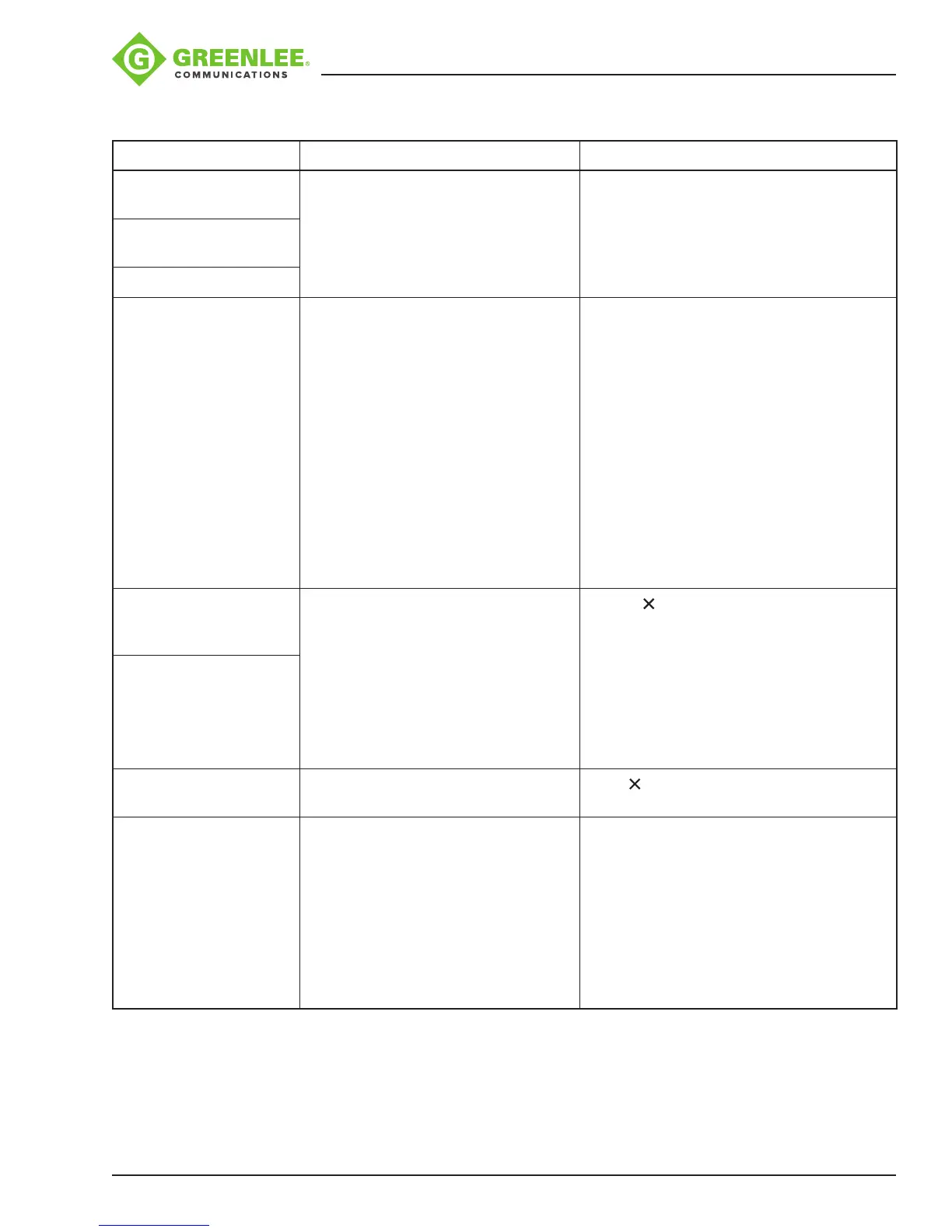

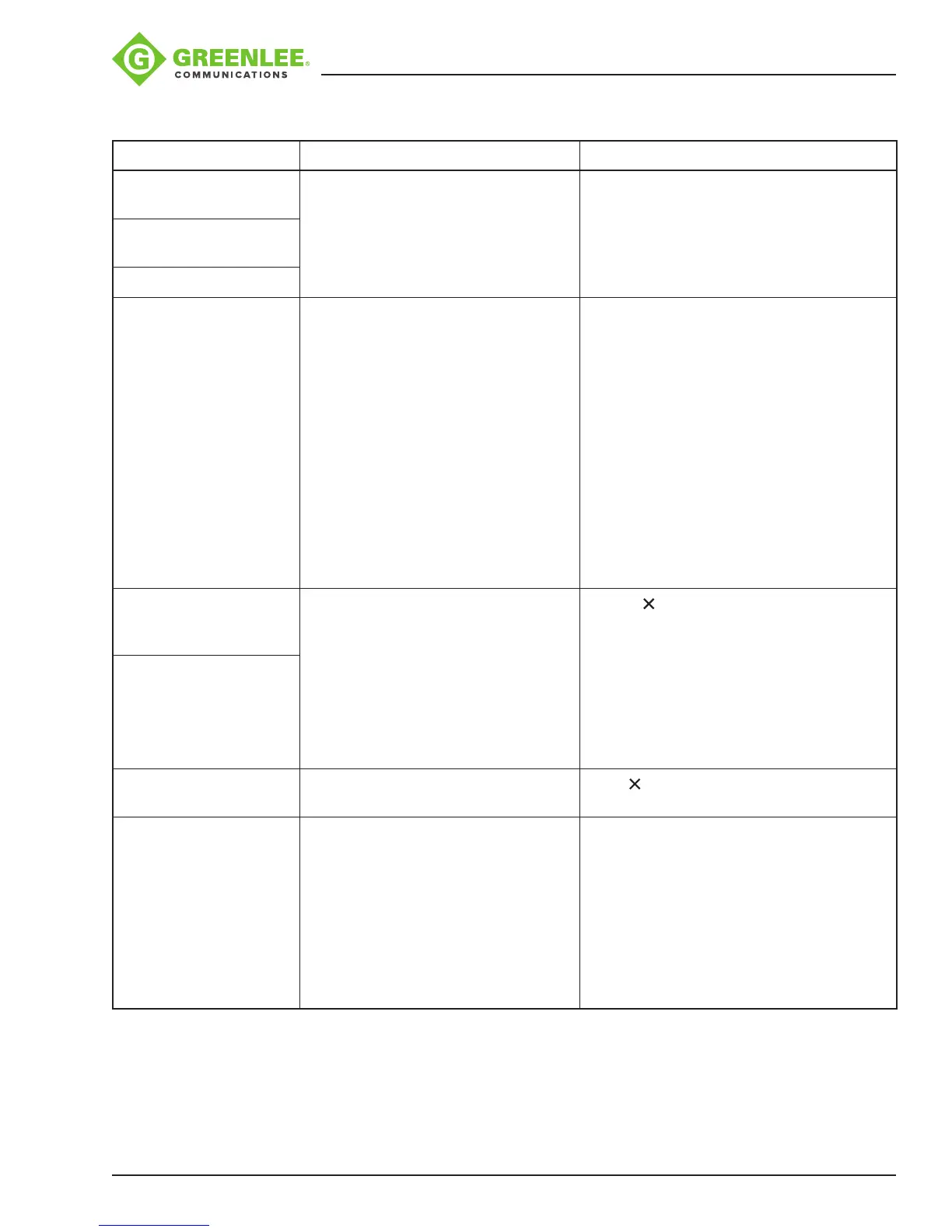

Error Messages

Error Message Reason Solution

Left/Right/L-R ber set

too close!

• The ber end-face is placed on the

electrode centerline, or beyond it.

• The cleave length (bare ber part) is

too long.

• Dust or dirt is on the objective lens

or the wind protector mirror.

• Conrm the setting position of the

stripped ber end on the ber cleaver.

Check the cleave length.

• Clean the lens or the mirror when dust or

dirt exists.

Left/Right/L-R ber set

too far!

Reset Left/Right bers!

Clear Left/Right bers! • Dust or dirt is on the objective lens

or the wind protector mirror.

• “Cleaning Arc” time is too short or

OFF.

• Splicing indistinct core bers with

the SM or DS modes.

• “Align” is set to “Core” to splice

indistinct core bers when using

other splice modes.

• “Focus” is incorrectly set when

using other splice modes.

• Completely prepare the ber again (strip,

clean, and cleave).

• Clean the lens or the mirror if dust or dirt

exists.

• Set the “Cleaning Arc” time to “30ms.”

When splicing carbon-coated bers, set

to “100ms.”

• Use the MM mode to splice indistinct

core bers (i.e., MM ber).

• Set “Align” to “Clad” to splice indistinct

bers (i.e., MM ber).

• Set “Focus” to “Edge” to splice indistinct

core bers (i.e., MM ber). To splice

distinct core bers, enter “Auto” or the

correct focus value.

Left/Right ber X/Y set

error!

• The ber is not set correctly at the

bottom of the V-groove. The ber

position is out of focus range.

• Dust or dirt is on the ber surface

resulting in focus failure.

• Dust or dirt is on the objective lens

or the wind protector mirror.

• Press , and re-position the ber to seat

it correctly at the bottom of the V-groove.

• If bers are not shown, use “screen

adjust.” Follow the procedure displayed

to enable the entire ber to be displayed.

• Completely prepare the ber again (strip,

clean, and cleave).

• Clean the lens or the mirror if dust or dirt

exists.

X/Y Motor out of range!

Cover is open! The wind protector is opened during

splicing operation.

Press after closing the wind protector.

Left/Right/L-R ber

angle errors, shape

errors and clear left &

right errors

• “Core Angle Limit” is set too low.

• Dust or dirt is on the V-groove or the

clamp chip.

• Bad ber end-face.

• The splicer measures the core angle only

when using other splice modes. Increase

the “Core Angle Limit” to an adequate

limit. (1.0 degree is standard.)

• Clean the V-groove and clamp chip, and

set the bers again. If the error occurs

again, strip, clean, and cleave the bers.

• Check the condition of ber cleaver. If the

blade is worn, rotate the blade to a new

position.

Loading...

Loading...