G0645 Benchtop Mortising Machine

-17-

Operation Safety

SECTION 4: OPERATIONS

NOTICE

If you have never used this type of machine

or equipment before, WE STRONGLY REC

-

OMMEND that you read books, trade maga

-

zines, or get formal training before begin

-

ning any projects. Regardless of the con

-

tent in this section, Grizzly Industrial will

not be held liable for accidents caused by

lack of training.

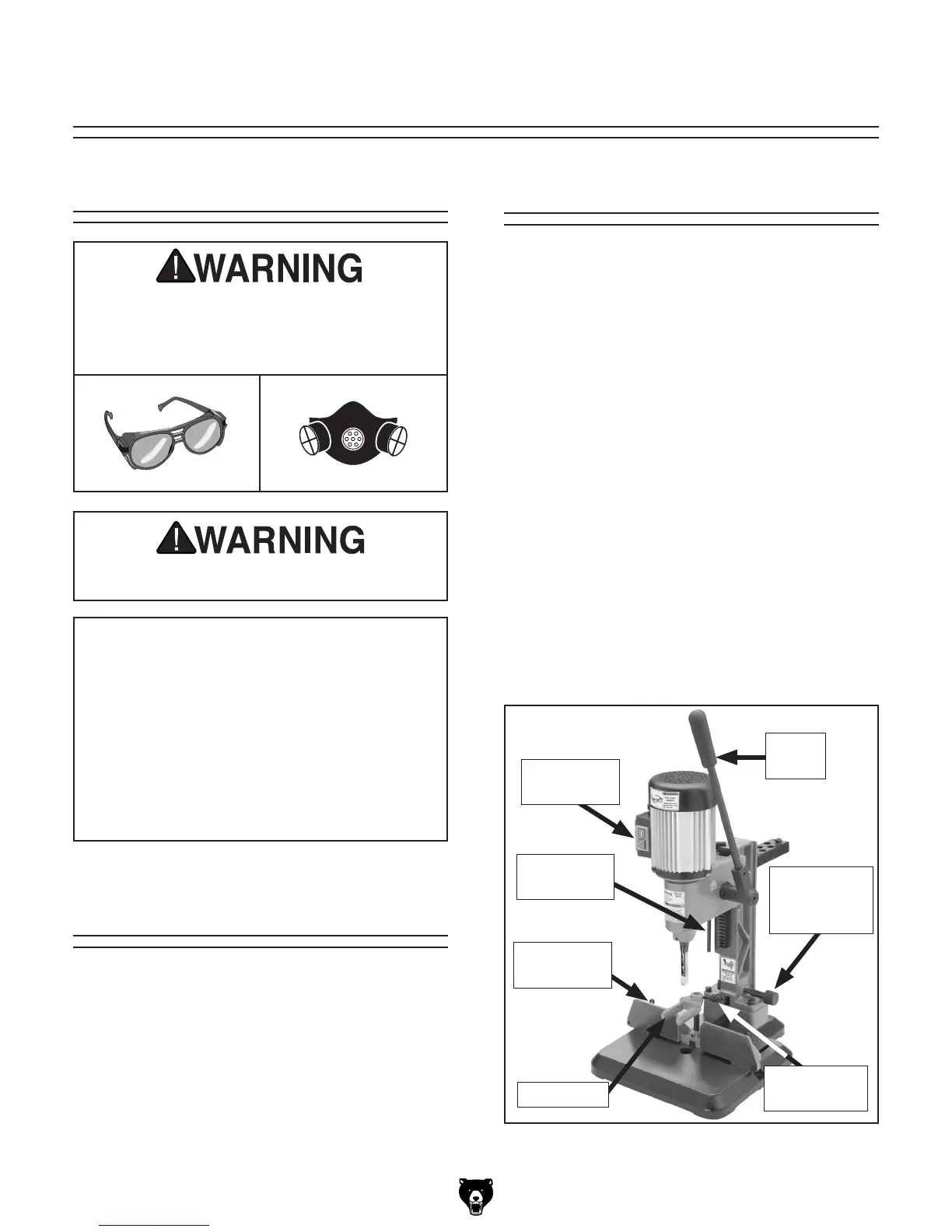

Basic Controls

Below is a summary of the basic controls used

during mortising operations. Use the list with

Figure 17

to become familiar with your mortising

machine.

ON/OFF Switch: Starts or stops motor.

Depth Stop Rod: Controls the mortise depth.

Hand Lever: Raises or lowers headstock.

Fence Lock Handles: Locks fence. When loos

-

ened, allows fence to move.

Fence Adjustment Knob: Moves fence back and

forth on the table—is disabled when the exten

-

sion block is installed.

Hold Down Lock Lever: Locks hold down.

Hold Down: Holds workpiece down when chisel

is raised after mortise is cut.

Damage to your eyes and lungs could result

from using this machine without proper pro

-

tective gear. Always wear safety glasses and

a respirator when operating this machine.

Figure 17. Model G0645 basic controls.

Hand

Lever

ON/OFF

Switch

Depth Stop

Rod

Fence Lock

Handle

Fence

Adjustment

Knob

Hold Down

Lock Lever

Hold Down

Basic Operations

This machine uses a hollow chisel with a drill bit to

cut square holes called mortises. After setting the

fence, depth stop, and hold down, use the hand

lever to lower the chisel and bit into the workpiece,

then raise the hand lever to remove the chisel and

bit from the workpiece.

Never mortise treated lumber—the smoke is

extremely poisonous.

Loading...

Loading...