-34-

Model G0761 (Mfd. Since 10/13)

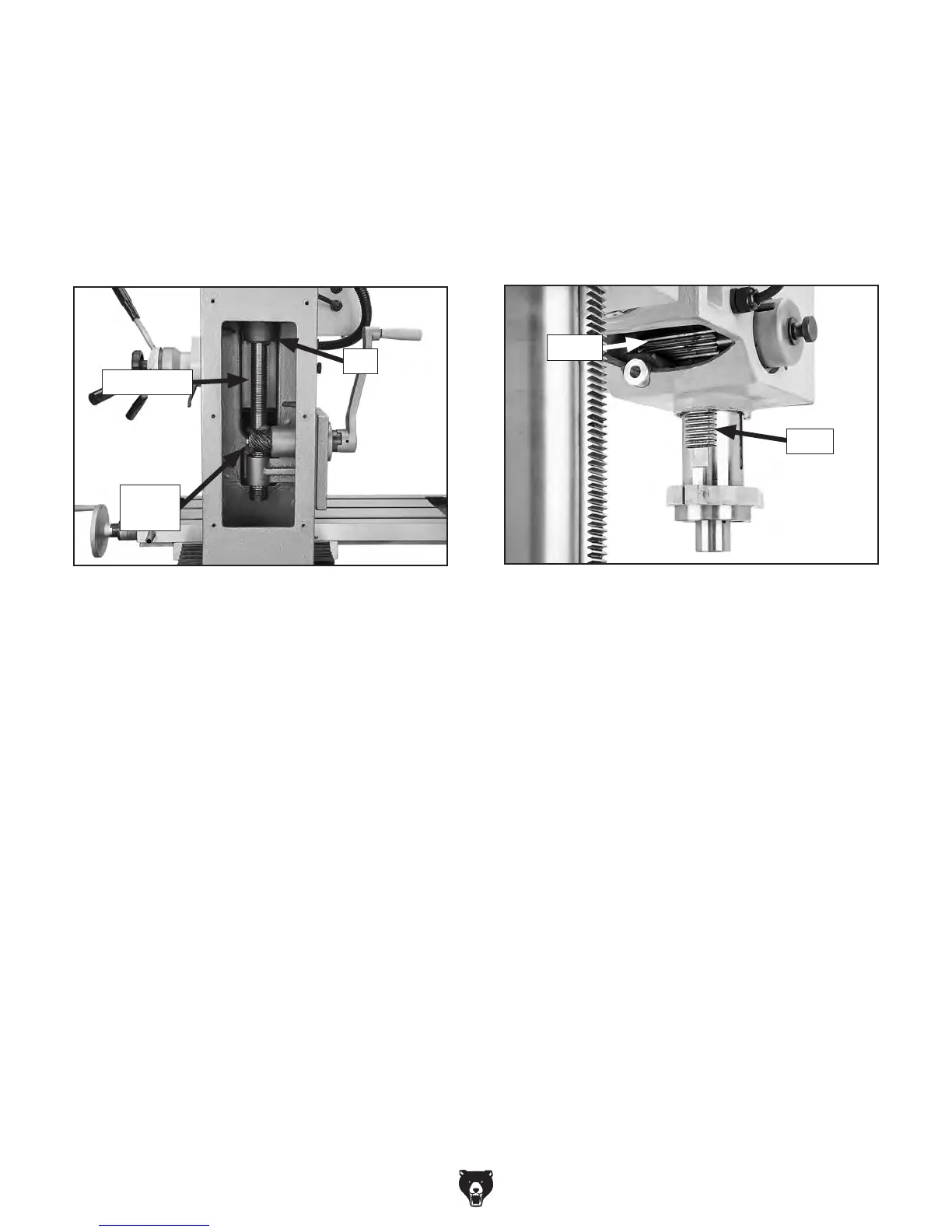

Quill Rack & Pinion

Lube Type . . Model T23964 or NLGI#2 Equivalent

Lube Amount ........................................Thin Coat

Lubrication Frequency ......... 90 hrs. of Operation

Move the quill up and down to gain full access

to the quill rack and pinion (see Figure 45), then

clean the teeth with mineral spirits, shop rags, and

a brush.

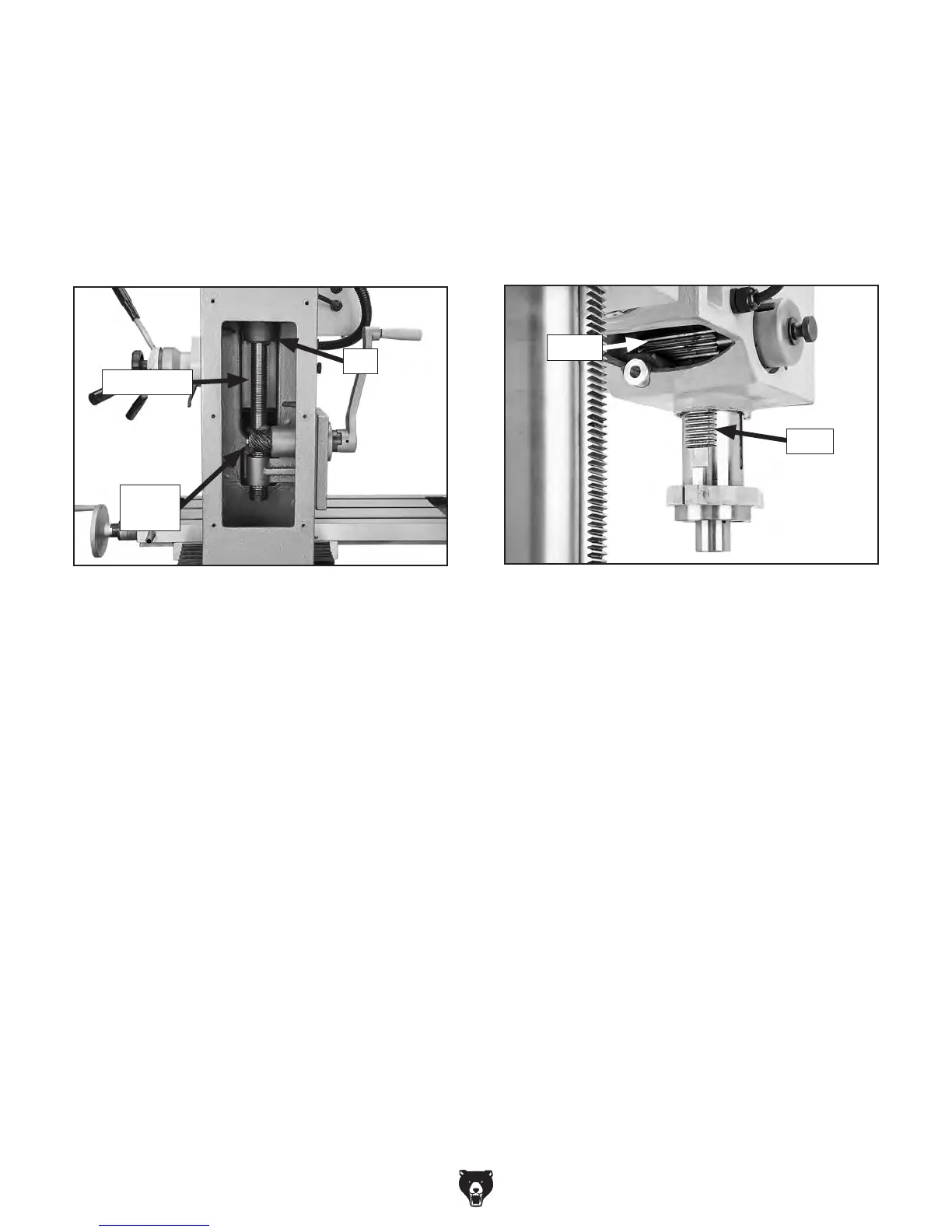

Column Leadscrew, Nut, & Pinion

Gear

Lube Type . . Model T23964 or NLGI#2 Equivalent

Lube Amount ........................................Thin Coat

Lubrication Frequency ......... 90 hrs. of Operation

Using a 5mm hex wrench, remove the column

rear cover to access Z-axis leadscrew compo-

nents (see Figure 44).

When dry, use a brush to apply a thin coat of

grease to the teeth, then raise/lower the quill sev-

eral times to evenly distribute the grease.

Note: Re-apply oil to the quill outside smooth

surface that may have been removed during the

cleaning process.

Figure 45. Quill rack and pinion.

Pinion

Rack

Use shop rags, a stiff brush, and mineral spirits

to clean away the grease and grime from the

Z-axis components. When dry, apply a medium

coat of grease to the components and threads of

the leadscrew. Move the headstock up and down

a few times to evenly distribute the lubricant.

Re-install rear cover.

Figure 44. Column rear cover removed to

access Z-axis leadscrew components.

Nut

Leadscrew

Pinion

Gear

Loading...

Loading...