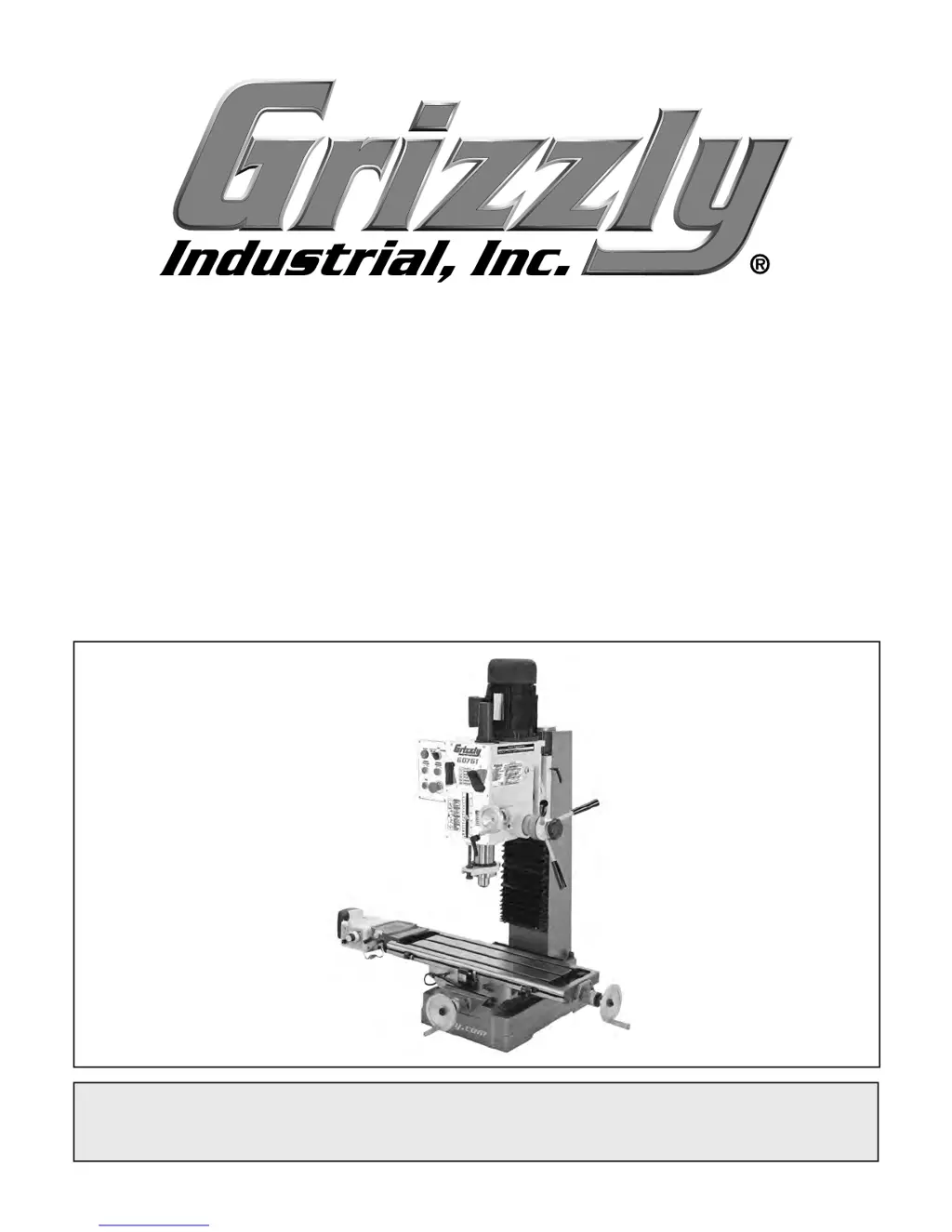

Why Grizzly Drill doesn't start?

- Llisa32Jul 29, 2025

If your Grizzly Drill doesn't start, several factors could be at play. First, check the plug for any damage and ensure it's wired correctly. Verify that the power supply voltage matches the circuit requirements. Also, inspect the wall fuse or circuit breaker to see if it's blown or tripped; if so, reset the breaker or replace the fuse after ensuring there isn't a short circuit. Examine the wiring for any breaks, disconnections, or corrosion, and repair or replace as needed. Check the spindle switch to ensure it's wired correctly, and replace it if faulty. If these steps don't resolve the issue, the motor wiring or the motor itself may be at fault and require testing, repair, or replacement.