-4-

Model G7945/G7946 (Mfd. Since 09/17)

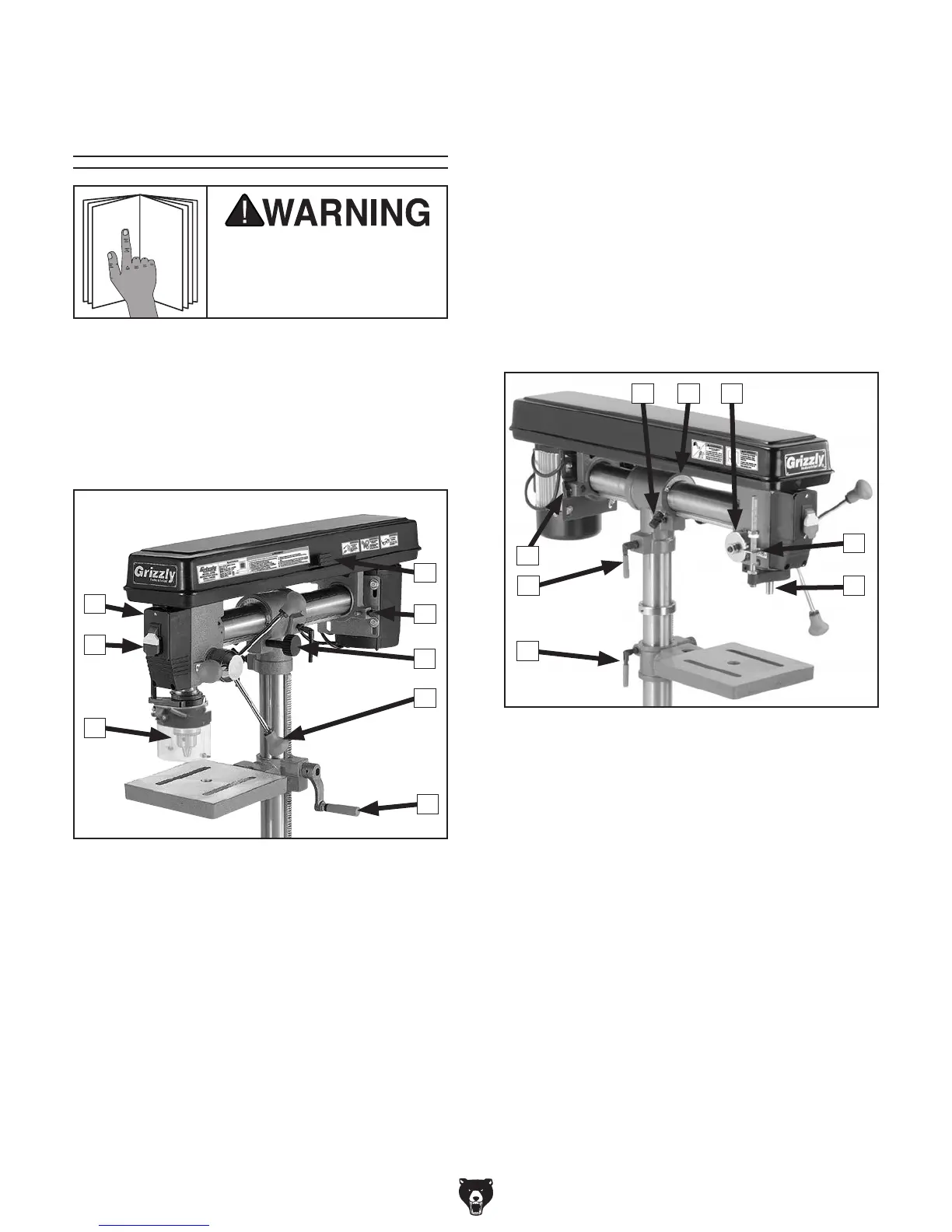

Controls &

Components

To reduce your risk of

serious injury, read this

entire manual BEFORE

using machine.

Refer to the following figures and descriptions to

become familiar with the basic controls and com-

ponents of this machine. Understanding these

items and how they work will help you understand

the rest of the manual and minimize your risk of

injury when operating this machine.

A. Power Switch: Turns motor ON/OFF.

B. Headstock: The cast-iron upper portion of

the drill press, which houses the quill and

supports the motor and belt housing.

C. Belt Cover: Provides access to drive belt for

spindle-speed changes.

D. Belt Tension Lock Knobs: Secures motor in

position to set belt tension.

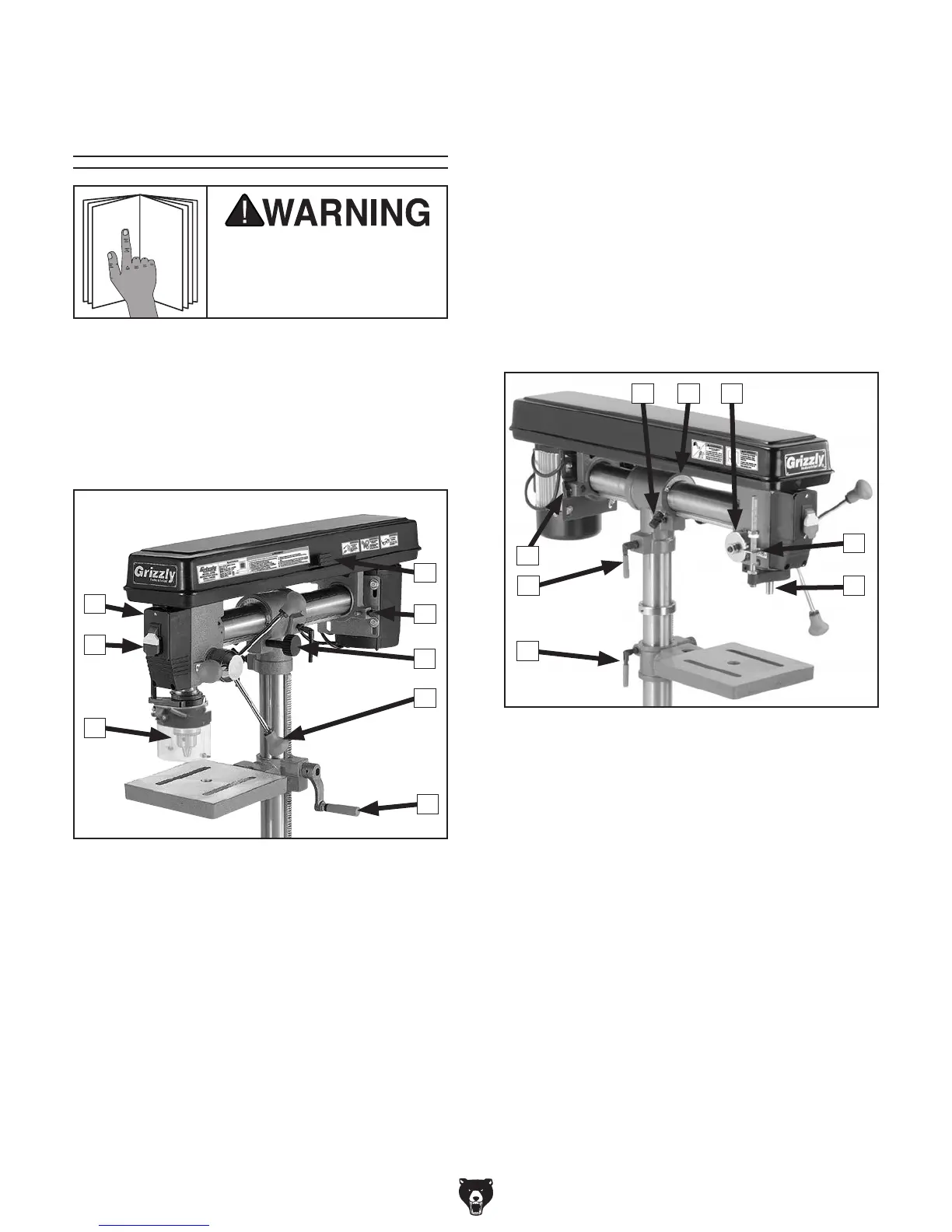

I. Headstock 90° Lock Pin: Engages when

headstock is positioned with spindle at 90° to

table. When pulled out, allows headstock to

be tilted left/right.

J. Scale: Indicates headstock angle.

K. Spindle Return Spring: Automatically

returns quill into headstock.

L. Depth Stop: Limits quill travel to a pre-set

drilling depth.

M. Spindle: Used to mount chuck and milling

accessories with a JT#33 taper.

N. Table Rotation Lock Lever: Locks table

rotation.

O. Column Lock Lever: Locks table height.

Figure 2. Machine controls (right).

E. Horizontal Adjustment Knob: Moves the

headstock forward and backward over the

column.

F. Downfeed Handles: Move the quill up and

down.

G. Table Height Crank Handle: Raises/lowers

table.

H. Chuck Guard & Chuck: Chuck guard pro-

tects user from flying debris; chuck accepts

drill bits from

1

⁄16" to

5

⁄8" and mounts to the

spindle with a JT#33 taper.

G

B

C

E

Figure 3. Machine controls (left).

H

J

D

N

I

L

M

K

A

F

D

O

Loading...

Loading...