GROOMING MOWERS - SGM Series - Models SGM 48-60-72-84

16

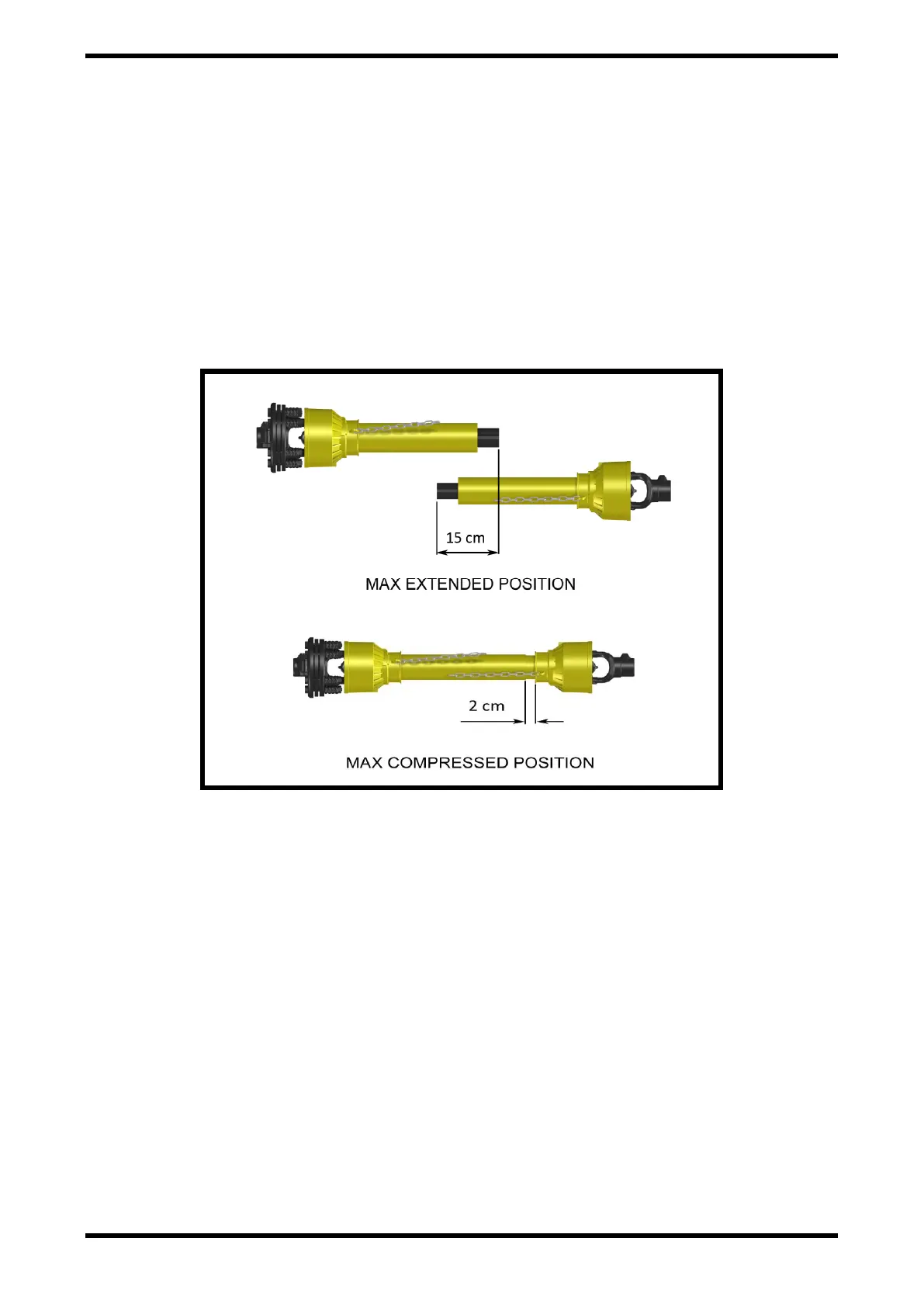

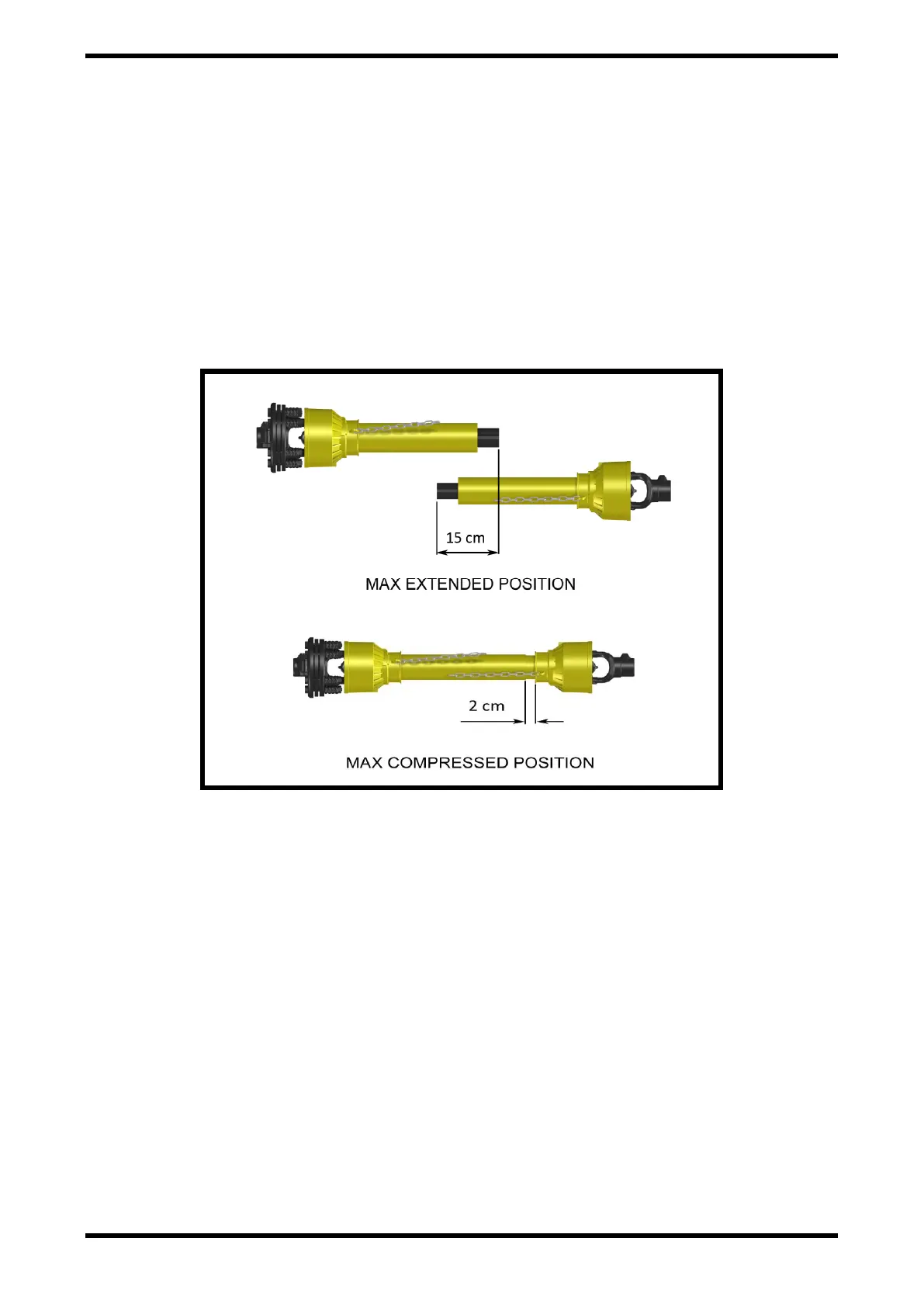

Before operating the mower, ensure that the size of driveshaft is adequate. The driveshaft sup-

plied with the machine has a standard length, therefore it may need an adaptation of the length,

depending of the tractor which the mower is combined.

The length of the driveshaft must be such to:

Avoid bottom out of the transmission tubes, when the driveshaft is in compressed position

(when the mower is raised up off the ground);

Ensure an overlapping of the transmission tubes enough to transmit the torque required, when

the driveshaft is in max extension (when the mower is in its lowest position in the ground).

When the driveshaft is at its minimum length (max compressed position), there must be at least a

2 cm of distance between the ends of each transmission tube and the yokes side.

When the driveshaft is at its maximum operational extension, there must be an overlap between

the tubes profiles of 15 cm at least.

A driveshaft too long may cause structural damages to the tractor and machine. If the driveshaft is

too long, it may be adapted by removing it and shortening the tubes according to the instructions

provided by the Manufacturer in its use and maintenance manual.

A driveshaft too short can cause disengage of the tubes during operation, with severe hazard for

the operator and structural damage to the tractor and machine. If the driveshaft is too short, it

must be replaced with a longer one. In this case contact the Manufacturer or your Dealer.

IMPORTANT

Before operating the mower the first time, or before reusing the mower after a long term stor-

age, make sure that the driveshaft is lubricated in accordance with how indicated in his own in-

struction booklet;

Always engage the tractor PTO at low rpm to minimize the effect of the peak torque on the

driveline and the machine.

Loading...

Loading...