English (GB)

22

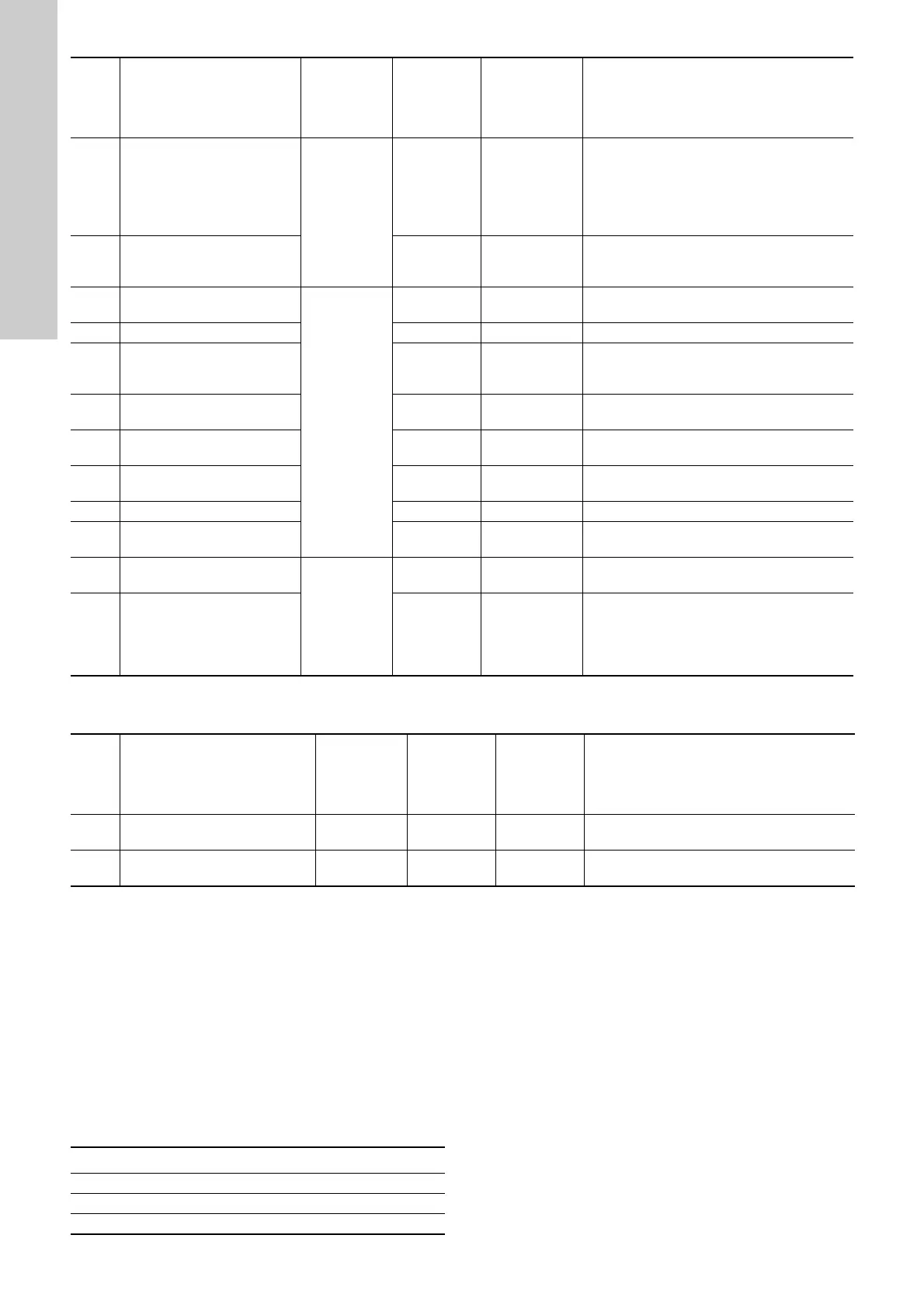

6.9 Special parameters, input explicit messaging

Special parameters are parameters that might be used by the PLC, but bear no relation to the operation of the digital dosing pump.

7. Product simulation

The CIM module can be put in product simulation mode in which

case it generates life-like simulated values of all the EtherNet/IP

input data parameters.

It will thus be possible to connect an EtherNet/IP master to CIU

500 without this device being connected to a real pump in a real-

life system. In an office environment, it can then be verified that

communication works and data is being received and handled

correctly by the master application program, for example PLC

program, before the equipment is installed under real-life

conditions.

Product simulation mode is entered via the webserver. See

section Webserver configuration on page 29.

The below functional profiles can be selected from the webserver.

Only input parameters are simulated. The data read has dummy

values and no real product functionality is simulated.

309 MeasuredPressure

SINT16, 0xC3

0.1 bar 0 - 3276.7 bar

Measured absolute pressure. The

SetFlowControlEnable bit (parameter 10)

must be set for this value to be available.

Except for the atmospheric pressure, it

corresponds to the “Backpressure” reading

on the display.

310 PulseInputFrequency 1 Hz 0 - 32767 Hz

Frequency of pulse input. Can be an external

pulse input signal or pulses coming via the

TrigPulse (parameter 17) command.

311 RemainingDosingVolume

SINT32, 0xC4

0.001 ml 0 - 2147.5 l

Remaining volume to be dosed. Used in

“Batch” mode.

312 VolumeTotal 0.001 l 0 - 2147.5 m

3

Total volume dosed (non-resettable).

313 VolumeTripCounter 0.001 l 0 - 2147.5 m

3

Volume trip counter. Can be reset with

TrigResetVolumeCnt (parameter 18)

command.

314 NoOfPowerOns 1 0 - (2

31

-1)

The number of times the pump has been

powered on (non-resettable).

315 RunTime 1 min 0 - (2

31

-1) min

The amount of time the pump has been

dosing (non-resettable).

316 OperatingTime 1 min 0 - (2

31

-1) min

The amount of time the pump has been

powered on (non-resettable).

317 StrokeCounter 1 0 - (2

31

-1) Total number of strokes (non-resettable).

318 TimeToNextDosing 1 s 0 - (2

31

-1) s

Time to next dosing. Only available in

operating mode "Timer".

319 AnalogInput

SINT16, 0xC3

0.001 mA 0 - 20.000 mA

Analog input value. The value is used as

setpoint in operating mode "Analog".

320 AnalogOutput 0.001 mA 0 - 20.000 mA

Analog output value. The parameter to map

to the output is selected via the operating

panel. If controlled from bus is selected, the

analog output signal can be controlled from

SetAnalogOutput (parameter 34).

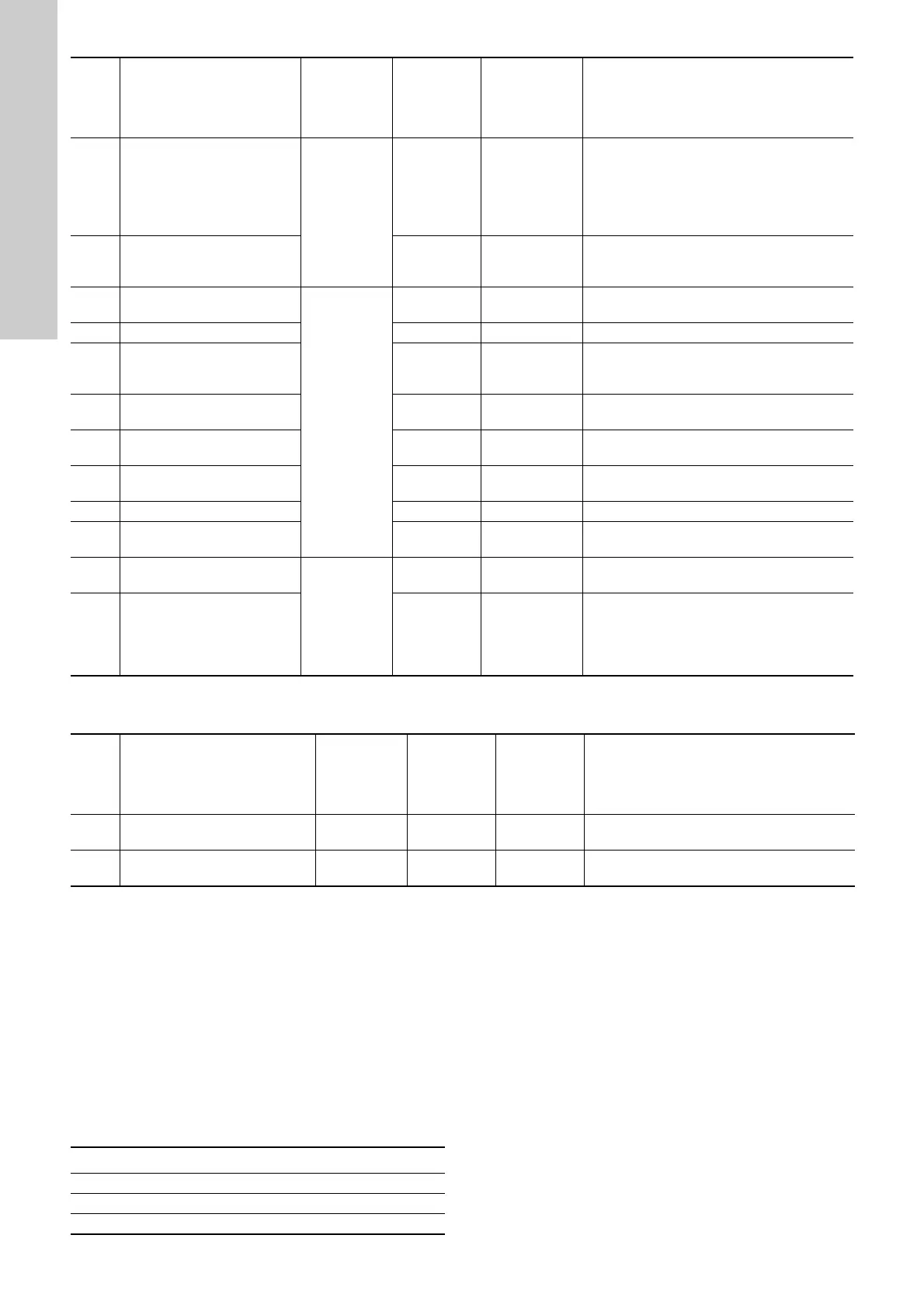

Parameters

Name Data type Scaling

Range/

Resolution

Description

Parameters

Name Data type Scaling

Range/

Resolution

Description

500 RPILimits UINT32, 0xC8 1 μs

15000 -

200000 μs

Requested Packet Interval

600 TCPIPCapability

DWORD32,

0xD3

- - For Logix EDS AOP integration

Simulated product

Pump profile

Booster system profile

Digital Dosing DDA profile

Loading...

Loading...