English (GB)

7

5. EtherNet/IP, CIM 500 setup

5.1 Connecting the Ethernet cable

Use RJ45 plugs and an Ethernet cable. Connect the cable shield

to protective earth at both ends.

CIM 500 is designed for flexible network installation; the built-in

two-port switch makes it possible to daisy chain from product to

product without the need of additional Ethernet switches. The last

product in the chain is only connected to one of the Ethernet

ports. Each Ethernet port has its own MAC address.

Fig. 3 Example of an Industrial Ethernet network with CIM

500

Fig. 4 CIM 500 Ethernet module

5.2 Selection of Industrial Ethernet protocol

The module has a rotary switch for selection of the Industrial

Ethernet protocol. See fig. 5.

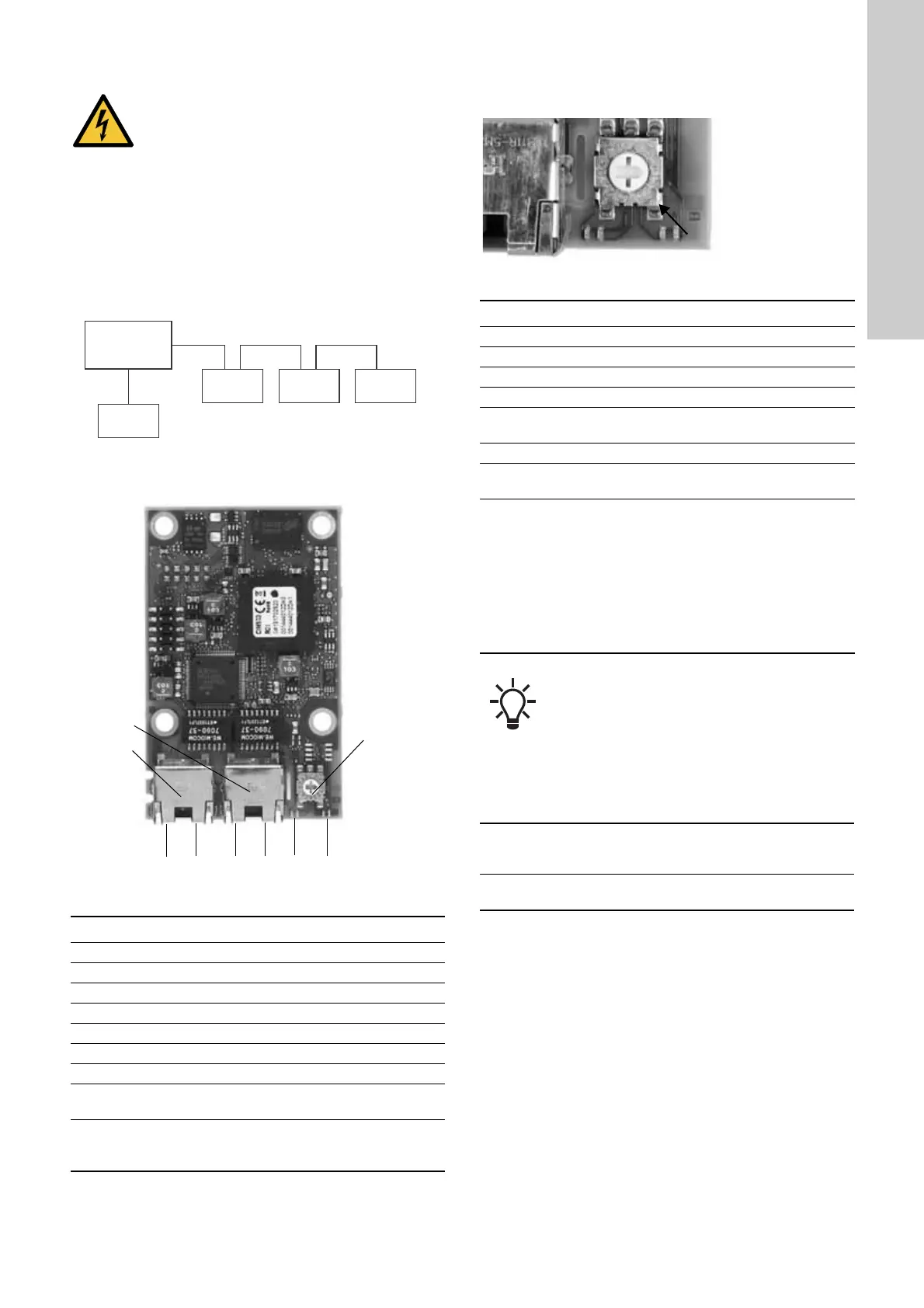

Fig. 5 Selecting the Industrial Ethernet protocol

5.3 Setting the IP addresses

The CIM 500 Ethernet module is by default set to a fixed IP

address. It is possible to change the IP address settings from the

built-in webserver.

WARNING

Electric shock

Death or serious personal injury

- Connect CIM 500 only to SELV or SELV-E circuits.

TM05 6435 4711TM05 7431 1013

Pos. Description Designation

1 Industrial Ethernet RJ45 connector 1 ETH1

2 Industrial Ethernet RJ45 connector 2 ETH2

3 Rotary switch for protocol selection SW1

4 Data activity LED for connector 1 DATA1

5 Link LED for connector 1 LINK1

6 Data activity LED for connector 2 DATA2

7 Link LED for connector 2 LINK2

8

Green and red status LED for Ethernet

communication

LED1

9

Green and red status LED for internal

communication between module and

pump

LED2

Ethernet

switch

CIM 500

CIM 500

CIM 500

CIM 500

TM05 7481 1013

Pos. Description

0 PROFINET IO, default

1 Modbus TCP

2 BACnet IP

3 EtherNet/IP

4

GRM IP for Grundfos Remote Management, requires a

contract with Grundfos.

5 Grundfos iSOLUTIONS Cloud (GiC)

6...E

Reserved. LED1 is permanently red to indicate an

invalid configuration.

F

Resetting to factory settings.

1. Set the rotary switch to this position

2. LED1 starts to flash red and green for 20 seconds to

indicate that factory resetting is about to take place.

3. After 20 seconds, LED1 stops to flash and factory

resetting is initiated.

4. When both LED1 and LED2 switch off, the resetting

is completed. The rotary switch can be moved to

another position.

If the rotary switch position is changed when the

module is powered on, the module will restart and

use the protocol associated with the new position.

Default IP settings

used by the

webserver

IP address: 192.168.1.100

Subnet mask: 255.255.255.0

Gateway: 192.168.1.1

IP settings for

EtherNet/IP

Make the settings via the webserver

Loading...

Loading...