English (GB)

27

The following settings are required in the "Setup >

Dosing timer week" menu for each dosing procedure:

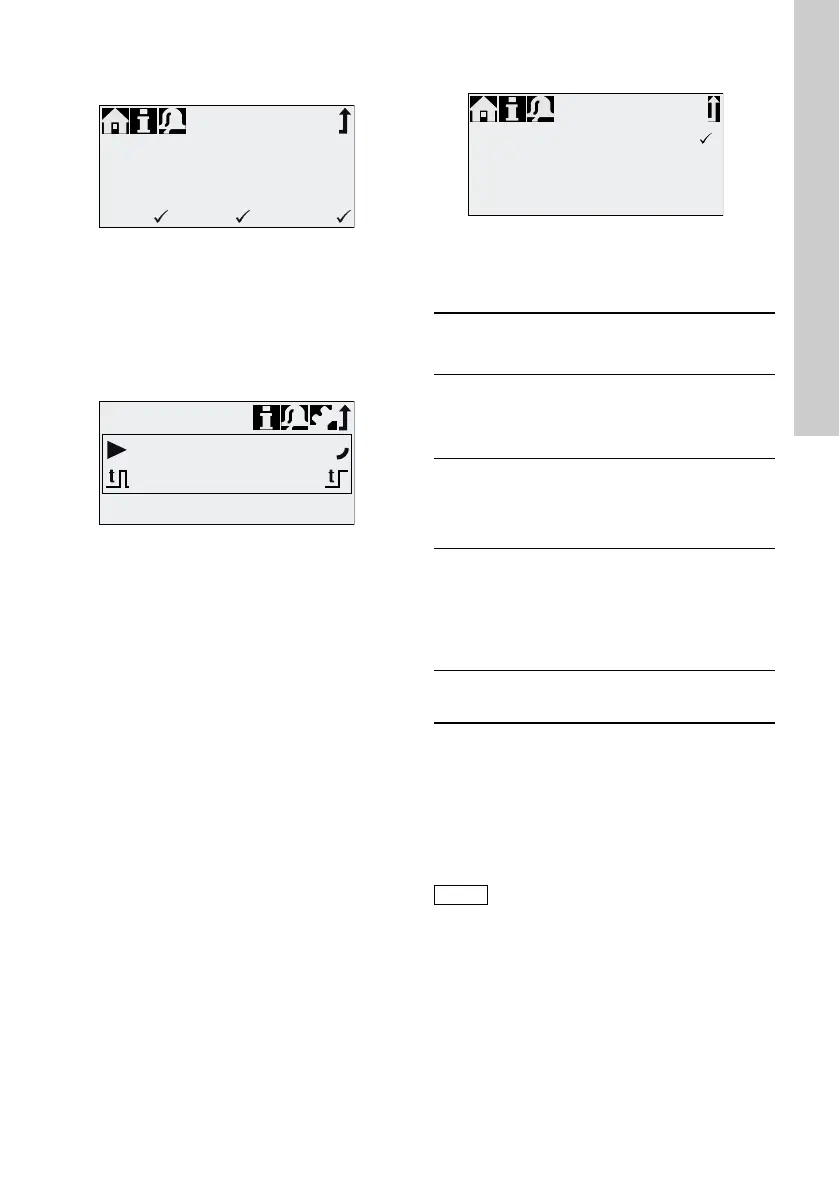

Fig. 29 Setting the timer

The batch volume (e.g. 80.5 ml) is set in the "Setup >

Dosing timer week" menu. The dosing time required

for this (e.g. 39.0) is displayed and can be changed.

In the "Operation" menu, the total batch volume

(e.g. 80.5 ml) and the remaining batch volume to be

dosed is displayed. During breaks in dosing, the time

(e.g. 43:32) until the next dosing is displayed.

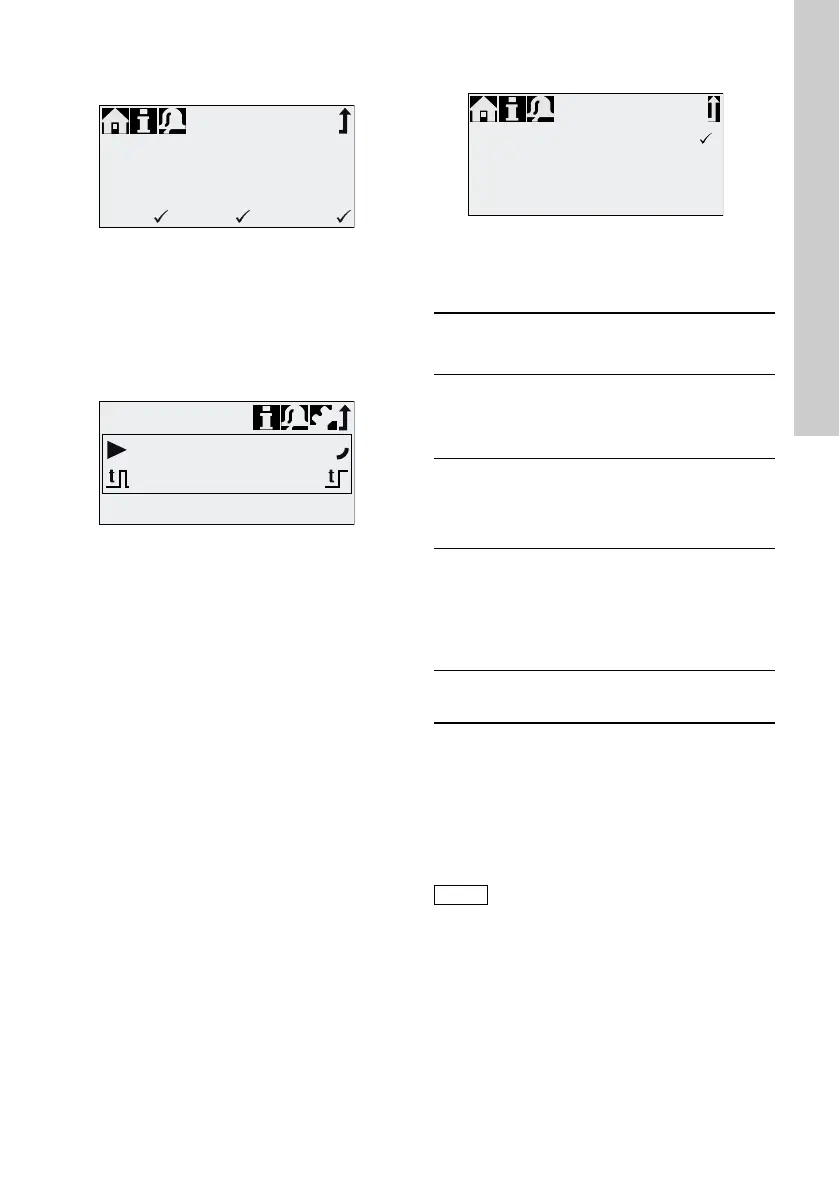

Fig. 30 Weekly timer dosing (break in dosing)

6.5 Analog output

Fig. 31 Configure analog output

The analog output of the pump is parametrised in the

"Setup > Analog output" menu. The following

settings are possible:

* Output signal is based on motor speed and pump

status (target flow).

** Signal has same analog scaling as the current

analog input signal. See 6.4.3 Analog 0/4-20 mA.

Wiring diagram see section 4.3 Electrical

connection.

TM04 1138 1110TM04 1136 1110

Timer

Procedure

Batch volume

Dosing time[s]

Start time[hh:mm]

1

80.5ml

39.0

05:00

M ❑T TW ❑F ❑S ❑S

Operation

80.5

ml

Timer

43:32

TM04 1153 1110

Setting

Description of output

signal

Variant

FCM

FC

AR

Output =

Input

The analog input signal is

mapped 1:1 to the analog

output (e.g. to control

several pumps using one

signal)

XXX

Actual

flow**

Current actual flow

• 0/4 mA = 0 %

• 20 mA = 100 %

see section 6.9 Flow

measurement

XX*X*

Backpres

sure

Backpressure, measured

in the dosing head

• 0/4 mA = 0 bar

• 20 mA = Max.

operating pressure

see section 6.8 Pressure

monitoring

XX

Bus

control

Enabled by command in

Bus control, see section

6.15 Bus communication

XXX

In all operation modes, the analog

output has a range of 4-20 mA.

Exception: Operation mode 0-20 mA.

Here, the analog output range is

0-20 mA.

Output = Input

Actual flow

Backpressure

Bus control

❑

❑

❑

Analog out

Loading...

Loading...