15

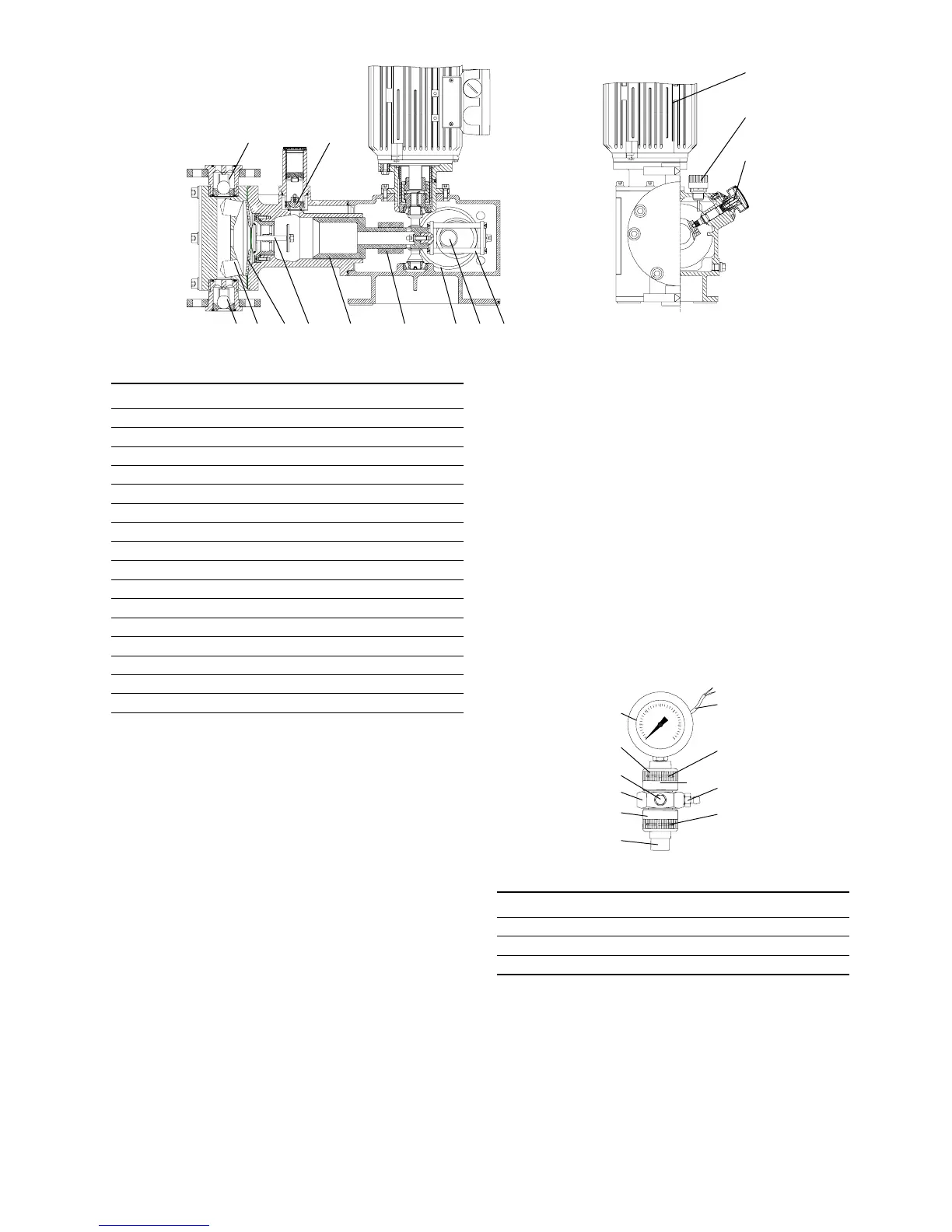

Fig. 6 DMH 257

8.1.1 Combined overpressure and degassing valve

The combined overpressure and degassing valve (M) opens if

there is an excessive pressure build-up in the dosing system and

provokes the constant degassing of the hydraulic medium.

8.1.2 Diaphragm protection system AMS

The diaphragm protection system AMS (9p) has a keypad, which

is connected to the dosing diaphragm. The dosing diaphragm

oscillates freely in the dosing head and cannot be overstretched

due to a fault in the dosing system since the diaphragm protection

valve closes if such a fault occurs.

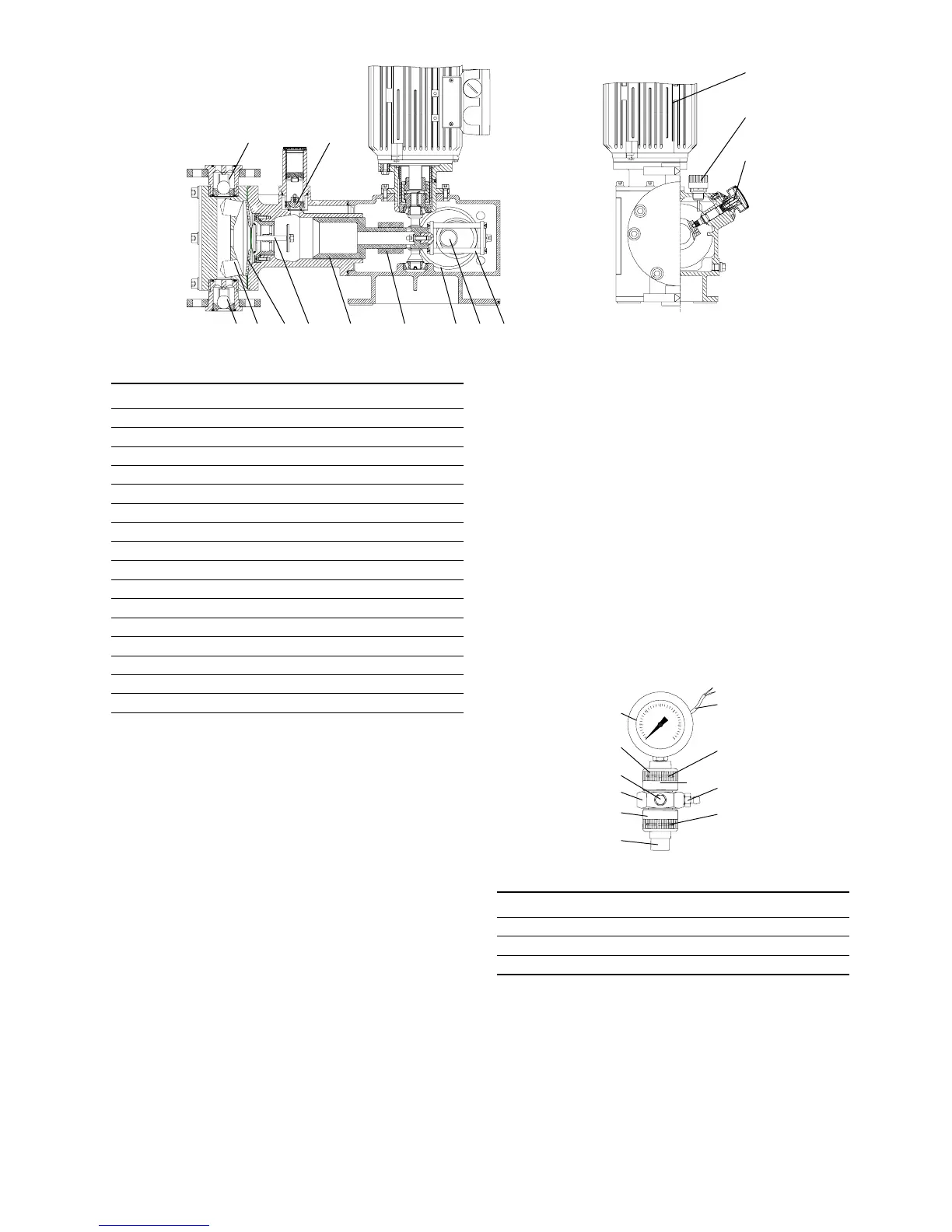

8.1.3 Double-diaphragm system / diaphragm leakage

detection (optional)

General

The piston diaphragm and high-tech dosing pumps with drift-free

diaphragm leakage detection are equipped with the following:

• dosing head with PTFE double-diaphragm system

• ball non-return valve with built-in contact pressure gauge.

Double-diaphragm system

Dosing pumps with a double-diaphragm system with no

diaphragm leakage detection have no pressure gauge. In this

case the ball non-return valve is fitted with a locking unit. The

valve, however, can be retrofitted with a contact pressure gauge.

Ball non-return valve

In order for the diaphragm leakage detection to work and to

protect the diaphragms, the gap must be fully deaerated. Dosing

heads with a double diaphragm are equipped with a ball non-

return valve (T) to prevent air from flowing back during the filling

and deaeration process (2u).

Fig. 7 Contact pressure gauge

2) For dosing heads with a double diaphragm with no contact

pressure gauge (no diaphragm leakage detection), a locking

unit is fitted instead of the contact pressure gauge.

TM03 6452 4506

1p

F

L

M3b

3a 9p 3p2p5p6p2Q 7p

Pos. Components

1p Motor

2p Worm gearing

3p Eccentric

4p Recuperating spring (not with drive size 3)

5p Sliding plug

6p Piston

7p Crank

M Combined overpressure and degassing valve

E Degassing valve

9p Diaphragm protection system (AMS)

Q Dosing diaphragm

2 Dosing head

3a Suction valve

3b Discharge valve

L Stroke-length adjustment knob

F Oil-filling screw with dipstick

TM03 6453 4506

Pos. Components

S Contact pressure gauge

T Ball non-return valve

U Connection piece

T

5u

4u

3u

2)

U

5s

3u

2u

S

6s

Loading...

Loading...