27

11.5 Zero point adjustments

11.5.1 Adjusting the zero point for system pressures up to

100 bar

The zero point of the dosing pump is factory-set to a slightly lower

counter-pressure than the rated pressure of the pump. If the

operating counter-pressure deviates considerably from this value,

an adjustment of the zero point will ensure more precise values.

Counter-pressure at the factory-set zero point of the pump

11.5.2 Adjusting the zero point

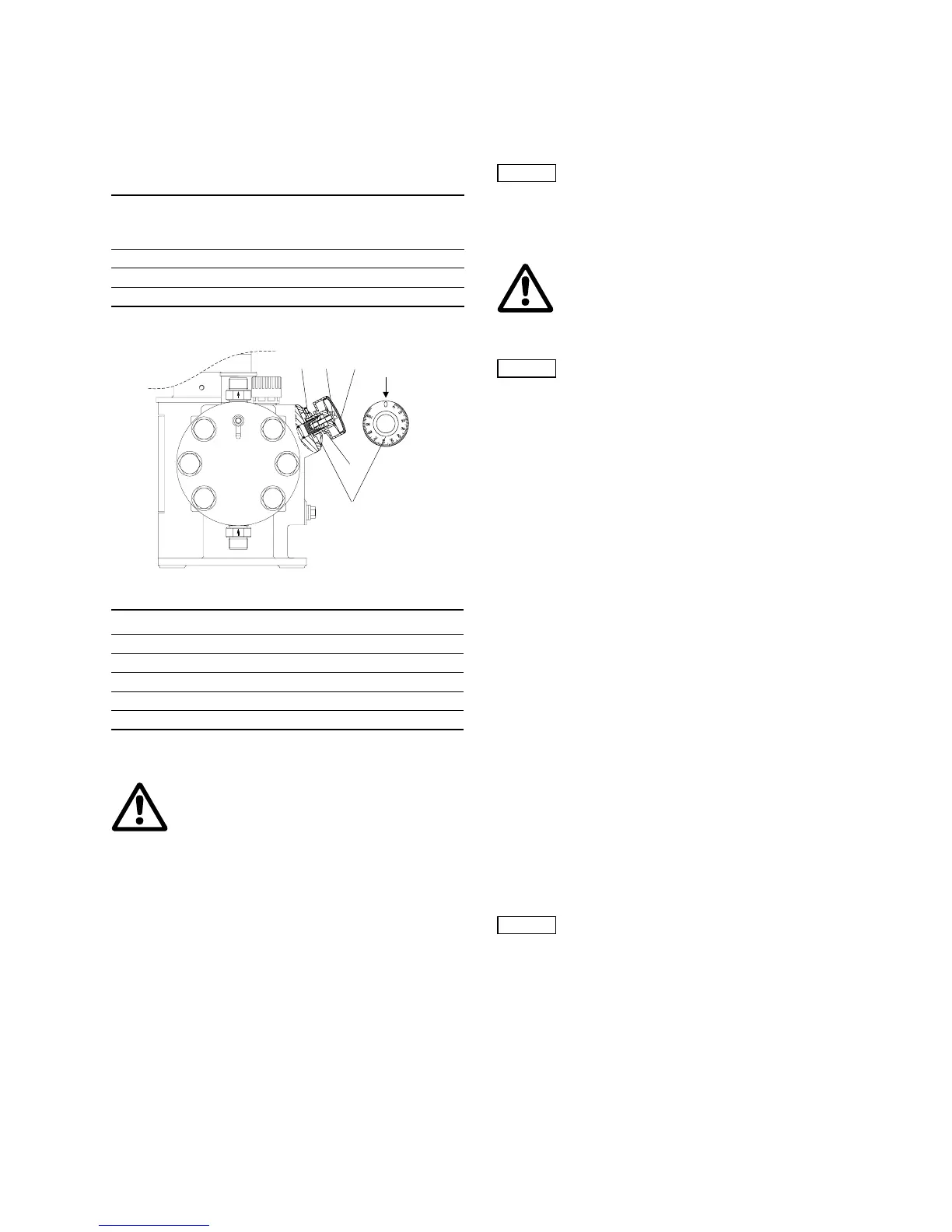

Fig. 30

Adjusting the zero point

1. Fit a measuring device on the suction side, for instance place

the suction line in a graduated measuring beaker.

2. Set the dosing flow to 15 %.

3. Remove the cover (1l) from the stroke-length adjustment knob

(L).

4. Use a screwdriver to loosen the locking screw (2l) by

approximately 2 turns.

5. Switch on the pump.

6. Slowly turn the stroke-length adjustment knob towards the

zero point until the dosing (the liquid level falls) stops in the

measuring device.

7. Switch off the pump.

8. Set the scale ring (4l) to zero.

– Loosen the screw (3l) in the scale ring (4l) slightly using an

hexagon key, M3.

– Turn the scale ring (4l) until both "0" are the same on the

scale and scale ring.

– Tighten the screw (3l).

9. Depending on the application, tighten the locking screw (2l) so

that the stroke-length adjustment knob can still be turned/

cannot be turned any more.

10.Replace the cover (1l).

11.6 Operating the pump

11.7 Shutdown

11.7.1 Switching off / uninstalling

1. Switch off the pump and disconnect it from the power supply.

2. Depressurise the system.

3. Take suitable steps to ensure that the returning dosing

medium is safely collected.

4. Carefully remove all lines.

5. Uninstall the pump.

11.7.2 Cleaning

1. Rinse all parts that have come into contact with the medium

very carefully:

– lines

– valves

– dosing head

– diaphragm.

2. Remove any trace of chemicals from the pump housing.

11.7.3 Storage

Storage of the pump:

1. After cleaning (see section

11.7.2 Cleaning), carefully dry all

parts and reinstall the dosing head and valves, or

2. change the valves and diaphragm.

See section

13. Maintenance.

11.7.4 Disposal

Disposal of the pump:

• After cleaning (see section

11.7.2 Cleaning), dispose of the

pump in accordance with the relevant regulations.

12. Operation

12.1 Switching on/off

• To start the pump, switch on the power supply.

• To stop the pump, switch off the power supply.

Rated pressure of the pump

[bar]

Counter-pressure at the

factory-set zero point

[bar]

10 3

16 3

25 10

TM03 6466 4506

Pos. Components

L Stroke-length adjustment knob

1l Cover

2l Locking screw

3l Screw

4l Scale ring

Warning

When dosing dangerous media, observe the

corresponding safety precautions!

Wear protective clothing (gloves and goggles)

when working on the dosing head, connections

or lines!

Always adjust the value with the discharge line

connected and with operating counter-pressure.

3l 2l 1l

4l

3l

L

Note

When operating the pump, see sections

12. Operation and 13. Maintenance and,

if necessary, section 14. Fault finding chart.

Warning

Wear protective clothing (gloves and goggles)

when working on the dosing head, connections

or lines!

Do not allow any chemicals to leak from the

pump. Collect and dispose of all chemicals

correctly!

Note

If possible, rinse the dosing head before shutting

down the pump, e.g. by supplying it with water.

Caution

Before switching on the pump, check that it is

installed correctly. See sections 9. Installation

and 11. Start-up / shutdown.

Loading...

Loading...