25

11.1.3 Filling the dosing head for the initial start-up for

systems without flooded suction

As assisting suction for systems without flooded suction, you can

fill the dosing head with dosing medium before the initial start-up:

1. Unscrew the discharge valve (3b).

2. Add the dosing medium to the dosing head (2).

3. Screw the discharge valve (3b) back in.

11.2 Start-up / subsequent start-up of DMH 251, 252

and 253

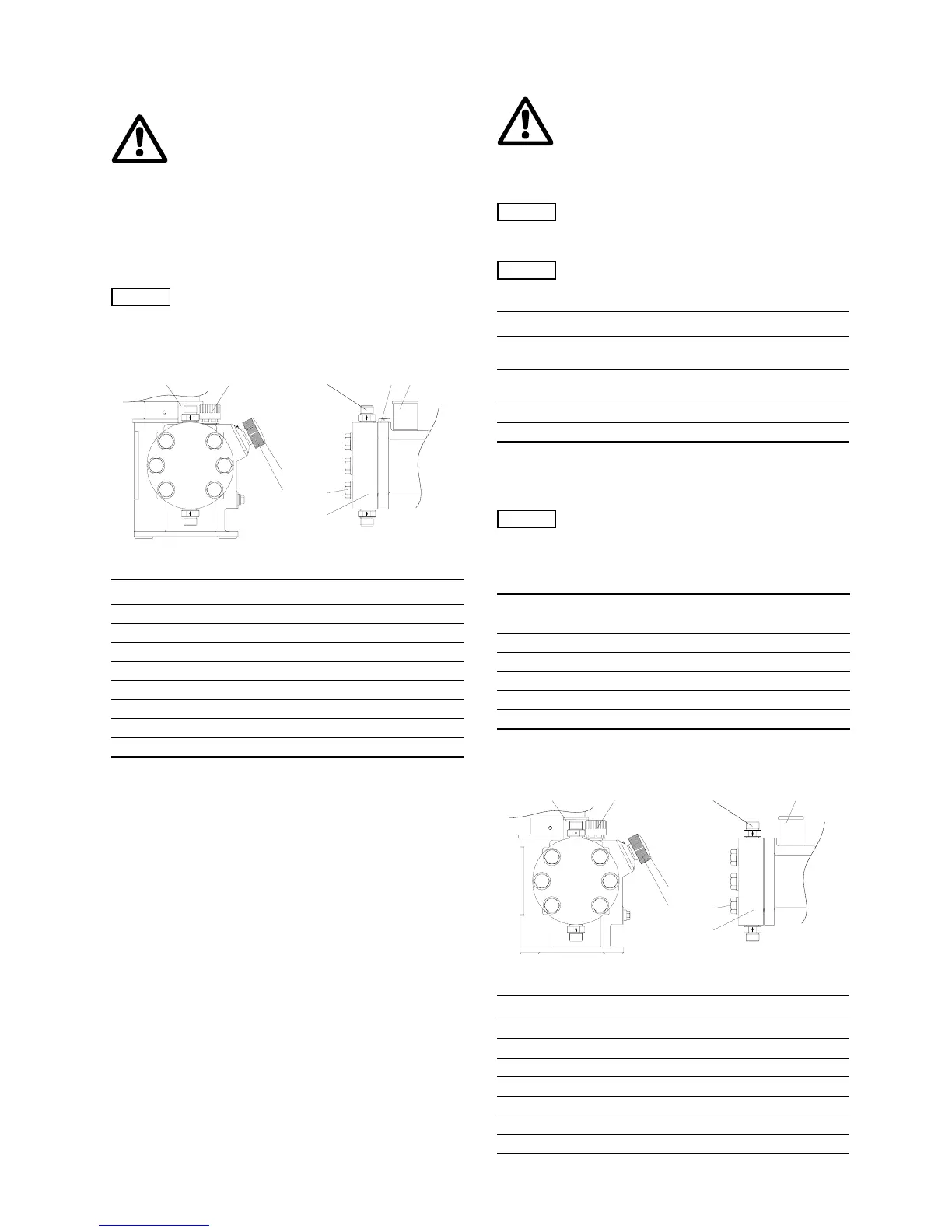

Fig. 26 Start-up of DMH 251, 252 and 253

1. Connect the electrical power supply.

2. Depending on the installation, start the pump, where possible,

without counter-pressure.

See installation example for easy deaeration of the dosing head

in section

9. Installation.

3. Set the stroke-length adjustment knob (L) to 0 %.

4. Let the pump run for approx. 5 minutes.

5. Check the oil level.

– Set the stroke-length adjustment knob (L) to 40 %.

– Let the pump run for approx. 10 minutes with a stroke-length

setting of 40 %.

– Switch off the pump, check the oil level and add oil,

if necessary.

– Refit the oil-filling screw (F).

6. Deaerate the piston flange.

– Set the stroke-length adjustment knob (L) to 15 %.

– Loosen the degassing valve (E) by one turn to the left.

– Let the pump run for approx. 5 minutes.

– Re-tighten the degassing valve (E).

The pump is now ready for operation.

After start-up

Torques

11.3 Start-up / subsequent start-up of DMH 254, 255

and 257

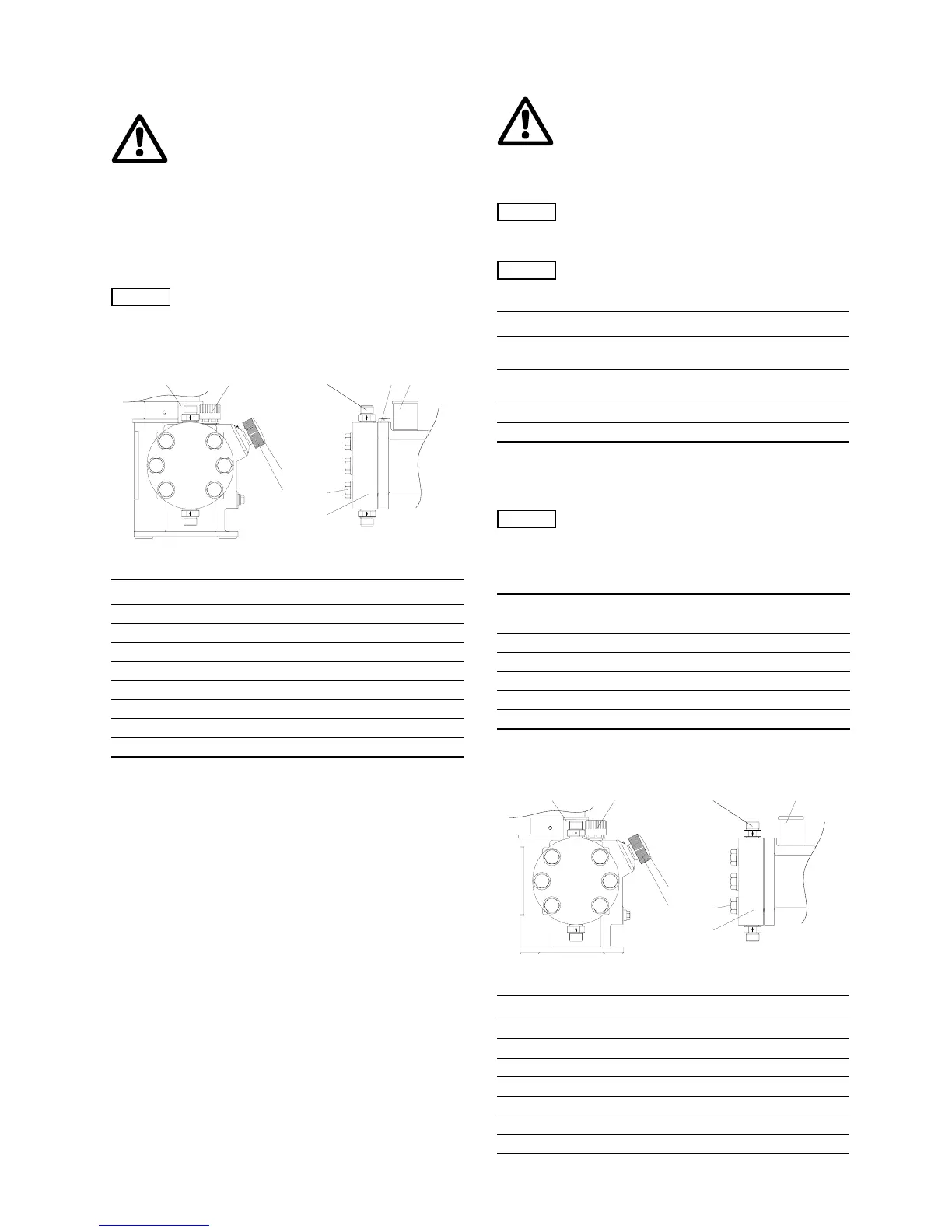

Fig. 27 Start-up of DMH 254, 255 and 257

Warning

When dosing dangerous media, observe the

corresponding safety precautions!

Wear protective clothing (gloves and goggles)

when working on the dosing head, connections

or lines!

Note

Observe the flow direction of the discharge valve

(indicated by an arrow on the valve)!

TM03 6462 4506

Pos. Components

1q Dosing head screws

2 Dosing head

3b Discharge valve

E Degassing valve

F Oil-filling screw with dipstick

L Stroke-length adjustment knob

1l Cover for stroke-length adjustment knob

M Pressure relief valve

L

F

1l

2

M M

1q

E

3b

Warning

Risk of injury caused by squirting oil!

Oil may squirt from the oil deaeration when the

pump is running. Do not completely unscrew the

oil deaeration screw.

Wear protective clothing (gloves and goggles)

when working on the dosing head, connections

or lines!

Note

Rod length of oil dipstick: 27 mm.

Immersion depth to marking: approx. 5 mm.

Note

Check the oil level at least every two weeks and

add oil, if necessary.

Only use original Grundfos Alldos gear oil!

For product number, see service instructions.

Pump type Version Description

DMH 251 Single/double

1.3 l white oil

(Paraffin 55 DAB7)

DMH 252, 10 bar Single/double

1.3 l white oil

(Paraffin 55 DAB7)

DMH 252, 16 bar Single/double 1.3 l DHG 68

DMH 253 Single/double 1.3 l DHG 68

Caution

After initial start-up and after each time the

diaphragm is changed, tighten the dosing head

screws.

After approximately 6-10 operating hours or

two days, cross-tighten the dosing head screws

using a torque wrench.

Pump type

Torque

[Nm]

DMH 251, 10 bar 8-10

DMH 251, 16 bar 10-12

DMH 251, 25 bar 13-15

DMH 252 8-10

DMH 253 10-12

TM03 6463 4506

Pos. Components

1q Dosing head screws

2 Dosing head

3b Discharge valve

F Oil-filling screw with dipstick

L Stroke-length adjustment knob

1l Cover for stroke-length adjustment knob

M Pressure relief valve

L

F

1l

2

M M

1q

3b

Loading...

Loading...