7

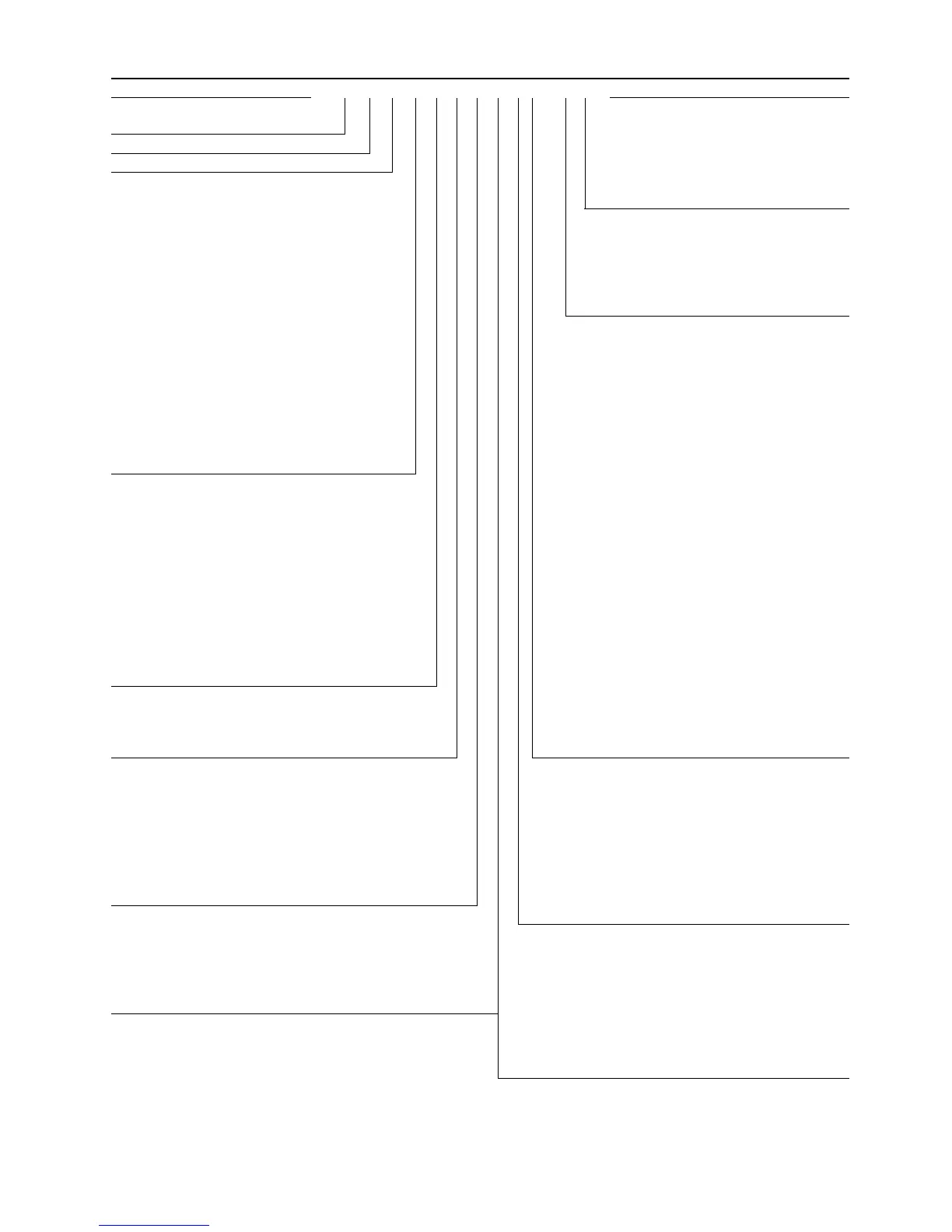

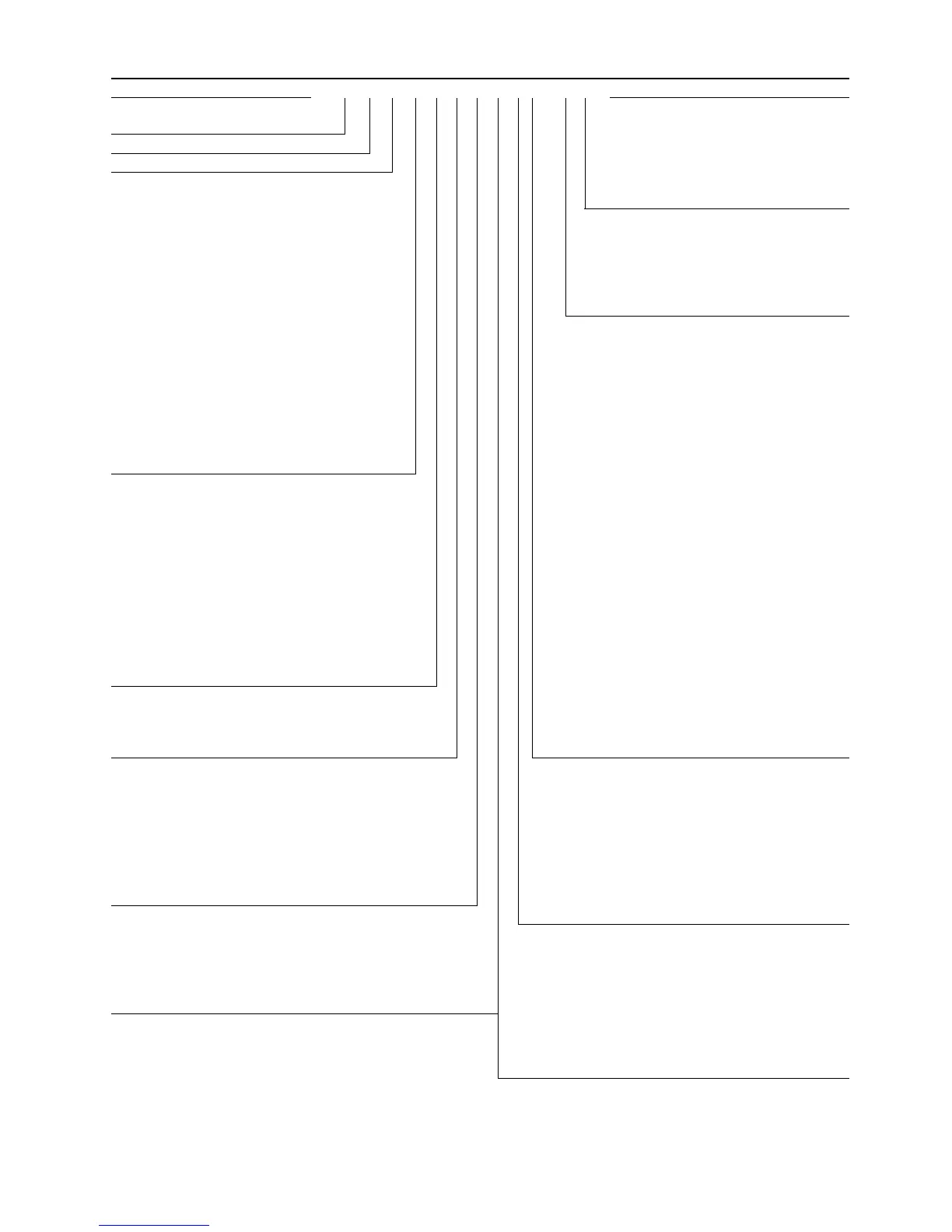

6.2 Type key

* Only pumps up to and including 0.37 kW and only single-phase pumps

Example:

DMH 100

- 10

AR PP /E /T -F -G 1

B9B9

FE0

Type range Motor variant

DMH E0 PTC motor for frequency control

Maximum flow [l/h]

E1 Motor type EEx de C T3, 3 x 400 V, 50 Hz

Maximum pressure [bar]

Control variant

E2 Motor type EEx de C T4, 3 x 400 V, 50 Hz

B Standard E3 API approval

AR* AR control unit (analog/pulse control)

Mains plug

S1 Stroke output X No plug

AT0 Prepared for servomotor F EU (Schuko)

AT3

Servomotor, 1 x 230 V, 50/60 Hz supply,

4-20 mA control

B USA, Canada

I Australia, New Zealand, Taiwan

AT5

Servomotor, 1 x 115 V, 50/60 Hz supply,

4-20 mA control

E Switzerland

Connection, suction/discharge

AT6

Servomotor, 1 x 230 V, 50/60 Hz supply,

4-20 mA control, EEx d II BT 4

B6 Pipe, 4/6 mm

C2 Pipe, 8/10 mm

AT7

Servomotor, 1 x 115 V, 50/60 Hz supply,

4-20 mA control, EEx d II BT 4

C4 Pipe, 20/25 mm

4 Tube, 6/9 mm

AT8

Servomotor, 1 x 230 V, 50/60 Hz supply,

4-20 mA control, 1 kΩ potentiometer

6 Tube, 9/12 mm

B9 Tube, 19/27 mm, PVC

AT9

Servomotor, 1 x 115 V, 50/60 Hz supply,

4-20 mA control, 1 kΩ potentiometer

Q Tube, 19/27 mm and 25/34 mm

S Tube, 3/8" / 1/2"

Dosing head variant

A Threaded, Rp 1/4, female

PP Polypropylene A1 Threaded, Rp 3/4, female

PV PVDF (polyvinylidene fluoride) V Threaded, 1/4" NPT, female

PVC Polyvinyl chloride A9 Threaded, 1/2" NPT, male

SS Stainless steel, DIN 1.4571 A3 Threaded, 3/4" NPT, female

Y Hastelloy

®

C A7 Threaded, 3/4" NPT, male

PP-L PP + integrated diaphragm leakage detection

B8 Cementing d. 40 mm and flange DN 32

PV-L PVDF + integrated diaphragm leakage detection

PVC-L PVC + integrated diaphragm leakage detection B1 Tube 6/12 mm/cementing d. 12 mm

SS-L SS + integrated diaphragm leakage detection

B2 Tube 13/20 mm/cementing d. 25 mm

Y-L Y + integrated diaphragm leakage detection

SS-H SS + heating flange in dosing head (electric) B3 Welding d. 16 mm

Gasket material

B4 Welding d. 25 mm

E EPDM B7 Welding d. 40 mm and flange DN 32

VFKM C1 Welding flange DN 32, stainless steel

TPTFE P Flange 1 1/4"

Valve ball material

Valve type

C Ceramics 1 Standard

GGlass 2

Spring-loaded

0.05 bar suction opening pressure;

0.05 bar discharge opening pressure

T

PTFE

3

Spring-loaded

0.05 bar suction opening pressure;

0.8 bar discharge opening pressure

SS Stainless steel, DIN 1.4401

Y Hastelloy

®

C 4

Spring-loaded, discharge side only,

0.8 bar opening pressure

Control panel position

5 For abrasive media

X No control panel

Supply voltage

F Front-mounted (opposite to the dosing head) 0 Without motor, IEC flange

S Side-mounted (same side as the stroke-length adjustment knob) F Without motor, NEMA flange (US)

Sx Side-mounted (side opposite to the stroke-length adjustment knob) G 1 x 230 V, 50/60 Hz

W Wall-mounted H 1 x 120 V, 50/60 Hz

5 3 x 230/460 V, 60 Hz

E

230/400 V, 50/60 Hz

440/480 V, 60 Hz

K 3 x 500 V 50 Hz

Loading...

Loading...