26

1. Connect the electrical power supply.

2. Depending on the installation, start the pump, where possible,

without counter-pressure.

See installation example for easy deaeration of the dosing head

in section

9. Installation.

3. Set the stroke-length adjustment knob (L) to 0 %.

4. Let the pump run for approx. 5 minutes.

5. Check the oil level.

– Set the stroke-length adjustment knob (L) to 40 %.

– Let the pump run for approx. 10 minutes with a stroke-length

setting of 40 %.

– Switch off the pump, check the oil level and add oil,

if necessary.

– Refit the oil-filling screw (F).

The pump is now ready for operation.

After start-up

Torques

11.4 Setting the pressure relief valve

The pressure relief valve is set to the pressure given by the

customer, or to the rated pressure (maximum counter-pressure).

The opening pressure can be set to a lower value by the

customer.

Opening pressure of the pressure relief valve

Setting the opening pressure

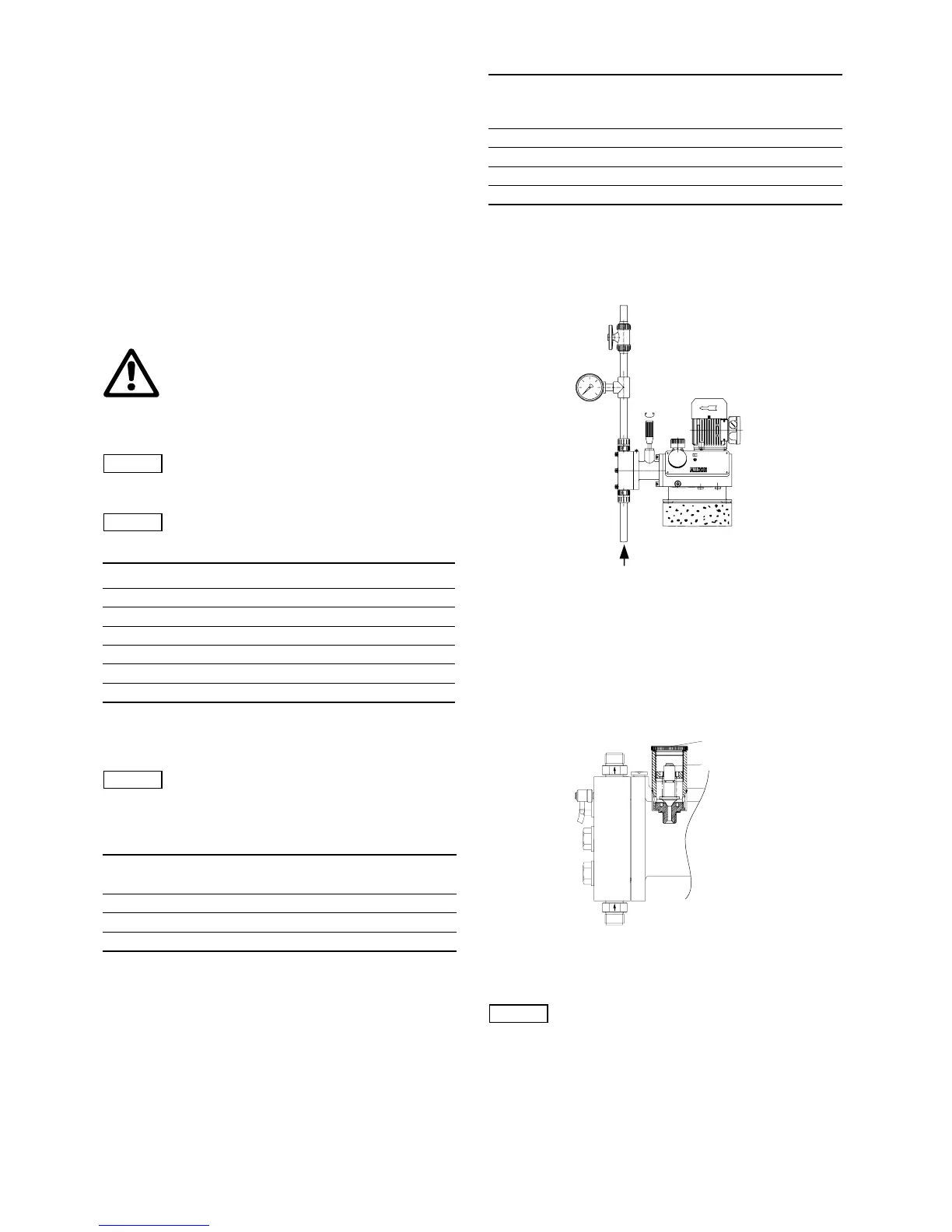

• To set the operating pressure, a pressure gauge must be

installed in the discharge line and an isolating valve must be

installed after the pressure gauge.

• To set the pressure relief valve, use a screwdriver.

Fig. 28 Setting the opening pressure

Set the pressure relief valve as follows:

1. Close the isolating valve after the pressure gauge.

2. Remove the cover (1m) from the pressure relief valve.

3. Start the pump.

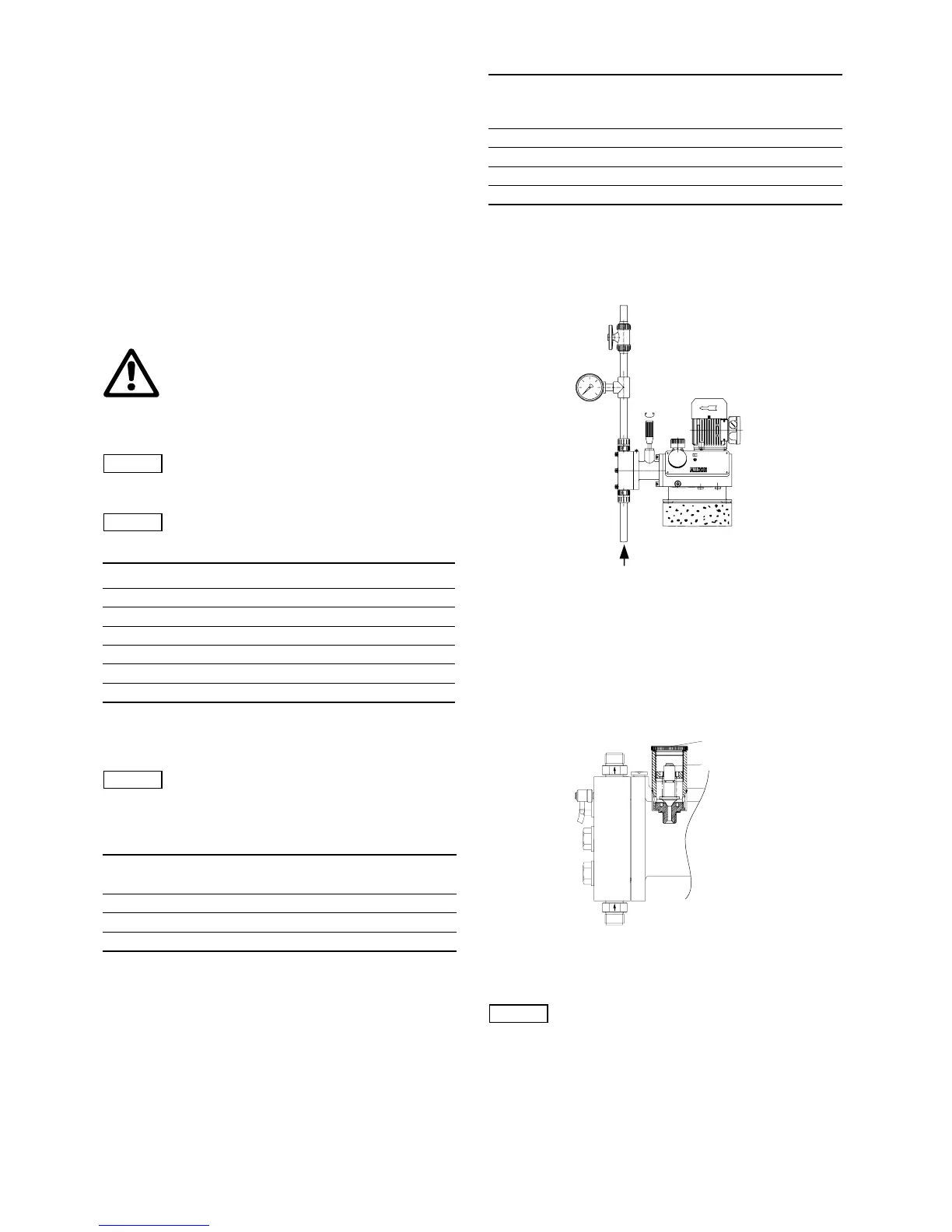

4. Using a screwdriver, slowly turn the adjusting screw (2m) of

the pressure relief valve counter-clockwise until the desired

opening pressure is obtained.

Fig. 29 Setting the pressure relief valve

5. Replace the cover of the pressure relief valve.

6. Open the isolating valve after the pressure gauge.

Warning

Risk of injury caused by squirting oil!

Oil may squirt from the oil deaeration when the

pump is running. Do not completely unscrew the

oil deaeration screw.

Wear protective clothing (gloves and goggles)

when working on the dosing head, connections

or lines!

Note

Rod length of oil dipstick: 35 mm.

Immersion depth to marking: approx. 5 mm.

Note

Check the oil level at least every two weeks and

add oil, if necessary.

Only use original Grundfos Alldos gear oil!

For product number, see service instructions.

Pump type Version Description

DMH 254 Single 3.5 l DHG 68

DMH 254 Double 4.5 l DHG 68

DMH 255 Single 3.5 l DHG 68

DMH 255 Double 4.5 l DHG 68

DMH 257 Single 5.5 l DHG 68

DMH 257 Double 7.5 l DHG 68

Caution

After initial start-up and after each time the

diaphragm is changed, tighten the dosing head

screws.

After approximately 6-10 operating hours or

two days, cross-tighten the dosing head screws

using a torque wrench.

Pump type

Torque

[Nm]

DMH 254 50-54

DMH 255 50-54

DMH 257 50-54

Rated pressure of the pump

[bar]

Opening pressure of the

pressure relief valve

[bar]

45

10 13

16 18

25 28

TM03 6464 4506TM03 6465 4506

Caution

Risk of damage to the pump or system!

When blocked, the pressure relief valve does not

work properly and can produce pressures of

several hundred bar in the pump or system.

Do not block the pressure relief valve during

adjustments!

2m

1m

Loading...

Loading...