40

Dm123.book Page 40 Tuesday, February 8, 2005 8:24 AM

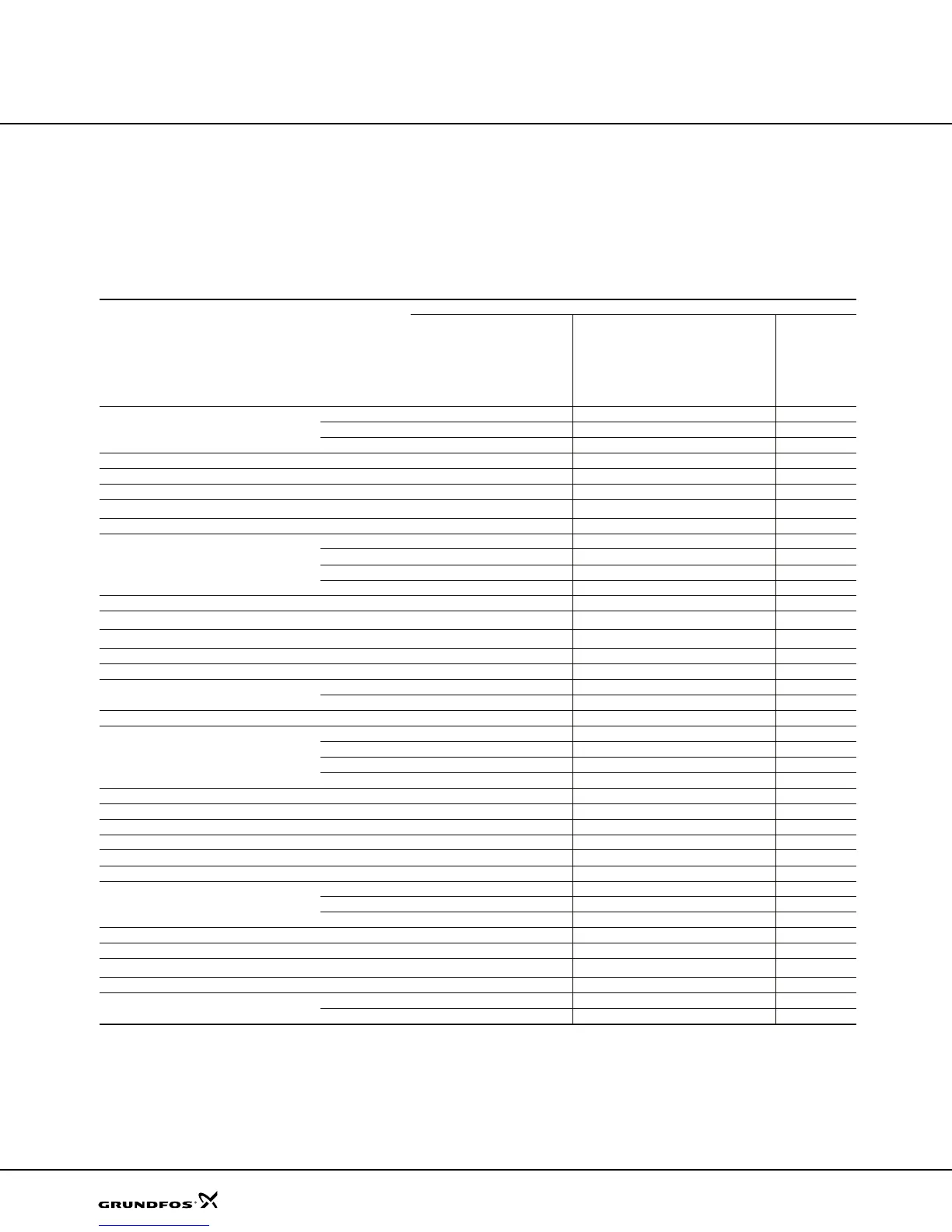

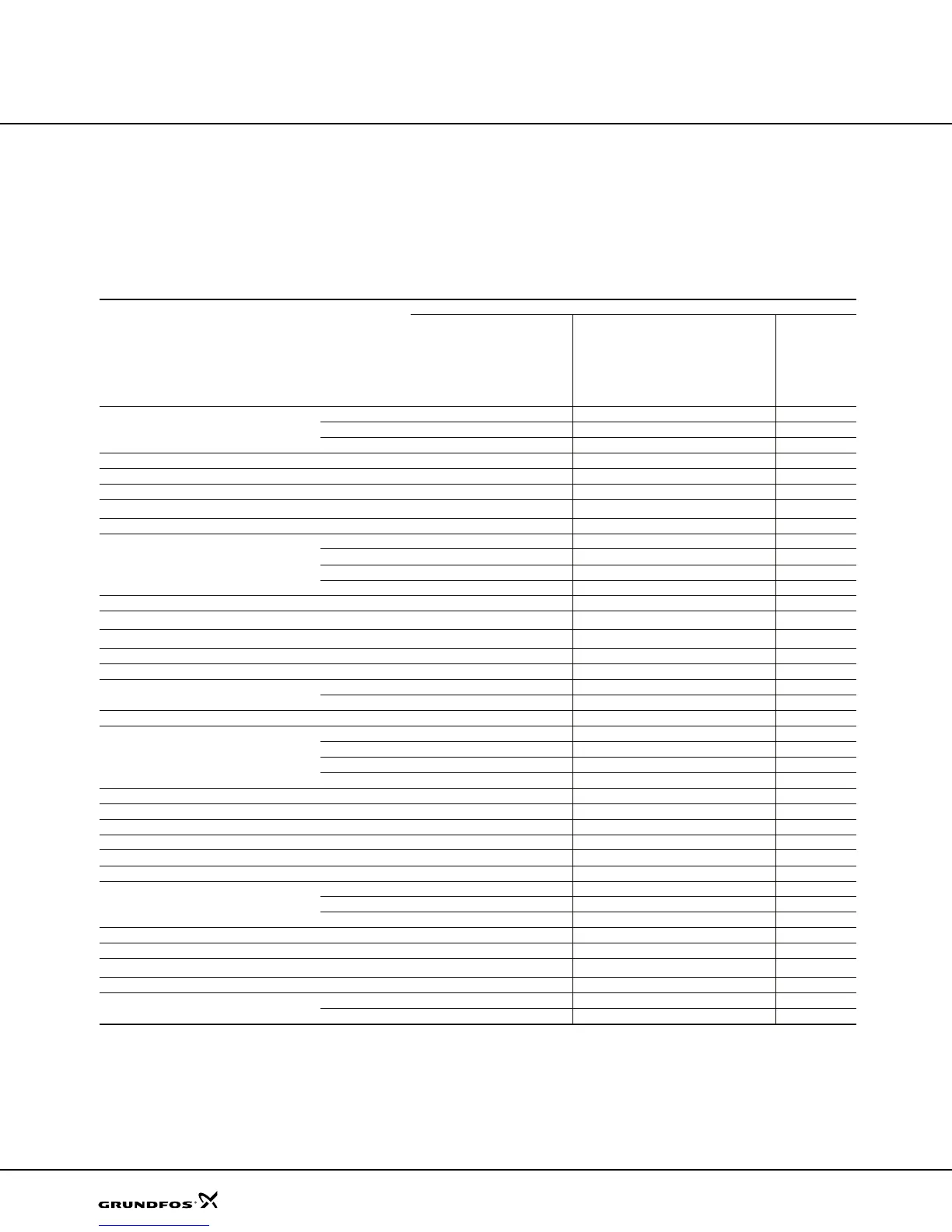

Pumped liquids

DME and DMS

List of pumped liquids

The resistance table below is intended as a general

guide for material resistance (at room temperature),

and does not replace testing of the chemicals and pump

materials under specific working conditions.

The data shown are based upon information from

various sources available, but many factors (purity,

temperature, abrasive particles, etc.) may affect the

chemical resistance of a given material. Note: Some of

the liquids in this table may be toxic, corrosive or

hazardous.

Please be careful when handling these liquids.

Pumped liquid 20°C

Concentration

%

Materials

Pump housing Gasket Ball

PP

PVDF

316 SS

PVC

FKM

EPDM

CSM

PTFE

Centellen C

Ceramic

Glass

Acetic acid CH

3

COOH

25 zzzz – zzzzz

60 zzzz – – zz z

85 zzz ––––zz z

Aluminium chloride AlCl

3

40 zz – zzzzzzzz

Aluminium sulphate Al

2

(SO

4

)

3

60 zzzzzzzzzzz

Ammonia, aqueous NH

4

OH 28 zzzz – zzzz–

Calcium hydroxide

7

Ca(OH)

2

zzzzzzzzzz –

Calcium hypochlorite Ca(OCl)

2

20 z – zzzzzzzz

Chromic acid

5

H

2

CrO

4

10 zzzzzzzzzzz

30 – z – zzzzzz

40 – z – zz – zzzz

50 – z – zz – zzzz

Copper sulphate CuSO

4

30 zzzzzzzzzzz

Ferric chloride

3

FeCl

3

100 zz – zzzzzzzz

Ferric sulphate

3

Fe

2

(SO

4

)

3

100 zzzzzzzzzzz

Ferrous chloride FeCl

2

100 zz – zzzzzzzz

Ferrous sulphate FeSO

4

50 zzzzzzzzzzz

Hydrochloric acid HCl

< 25 zz – zzzzzzz

25-37 zz – z – z – zz z

Hydrogen peroxide H

2

O

2

30 zzzzzzzzz

Nitric acid HNO

3

10 zzzzzzzzzzz

30 zzzzzzzz – zz

40 zzzzz – z – zz

70 – zz – z ––z – zz

Peracetic acid CH

3

COOOH 5 z – z – zzzzz

Potassium hydroxide KOH 50 z – zz– zzzz –

Potassium permanganate KMnO

4

10 zzzz – zzzzzz

Sodium chlorate NaClO

3

30 zzzzzzz zz

Sodium chloride NaCl 30 zz – zzzzzzzz

Sodium chlorite NaClO

2

20 z ––zzzzzzz

Sodium hydroxide NaOH

20 zz zz zzz –

30 z – zzzzzz –

50 z – zzzzzz –

Sodium hypochlorite NaOCl 20 z – zzzzzzzz

Sodium sulphide Na

2

S30zzzzzzzzzz –

Sodium sulphite

6

Na

2

SO

3

20 zzzzzzzzzz –

Sulphurous acid H

2

SO

3

6 zzzzzzzzzz

Sulphuric acid

4

H

2

SO

4

< 80 zz – zz zz

80-98 z ––z ––zzz –

z Suitable.

3

Risk of crystallisation.

Limited.

4

Reacts violently with water and generates much heat. (Pump should be absolutely dry before dosing sulphuric acid.)

– Not suitable.

5

Must be fluoride-free when glass balls are used.

6

In neutral solutions.

7

Saturated solution 0.1%.

Loading...

Loading...