English (GB)

17

10.1.1 Setpoint setting

Set the desired setpoint by pressing or . The setpoint can

be set on any of the pumps in the system and applies to the

complete booster system.

The light fields on the control panel will indicate the setpoint set.

Pump in constant-pressure control mode

Hydro Multi-E systems are as standard set up from factory as

pressure boosting systems, but can be set up to other control

modes. See CRI and CRIE IO installation and operating

instructions. The following example applies to a pump in an

application where a pressure sensor gives a feedback to the

pump. If the sensor is retrofitted to the pump, it must be set

manually as the pump does not automatically register a

connected sensor.

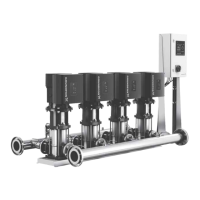

Figure 29 shows that the light fields 5 and 6 are activated,

indicating a desired setpoint of 3 bar with a sensor measuring

range from 0 to 6 bar. The setting range is equal to the sensor

measuring range.

Fig. 29 Setpoint set to 3 bar, constant-pressure control mode

Fig. 30 Constant pressure curve

Setting to maximum curve:

• Press

continuously to change over to the maximum curve

of the pump (top light field flashes). When the top light field is

on, press and hold for

for 3 seconds until the light field

starts flashing.

• To change back, press

continuously until the desired

setpoint is indicated.

Example: Pump set to maximum curve.

Figure 31 shows that the top light field is flashing, indicating

maximum curve.

Fig. 31 Maximum curve duty

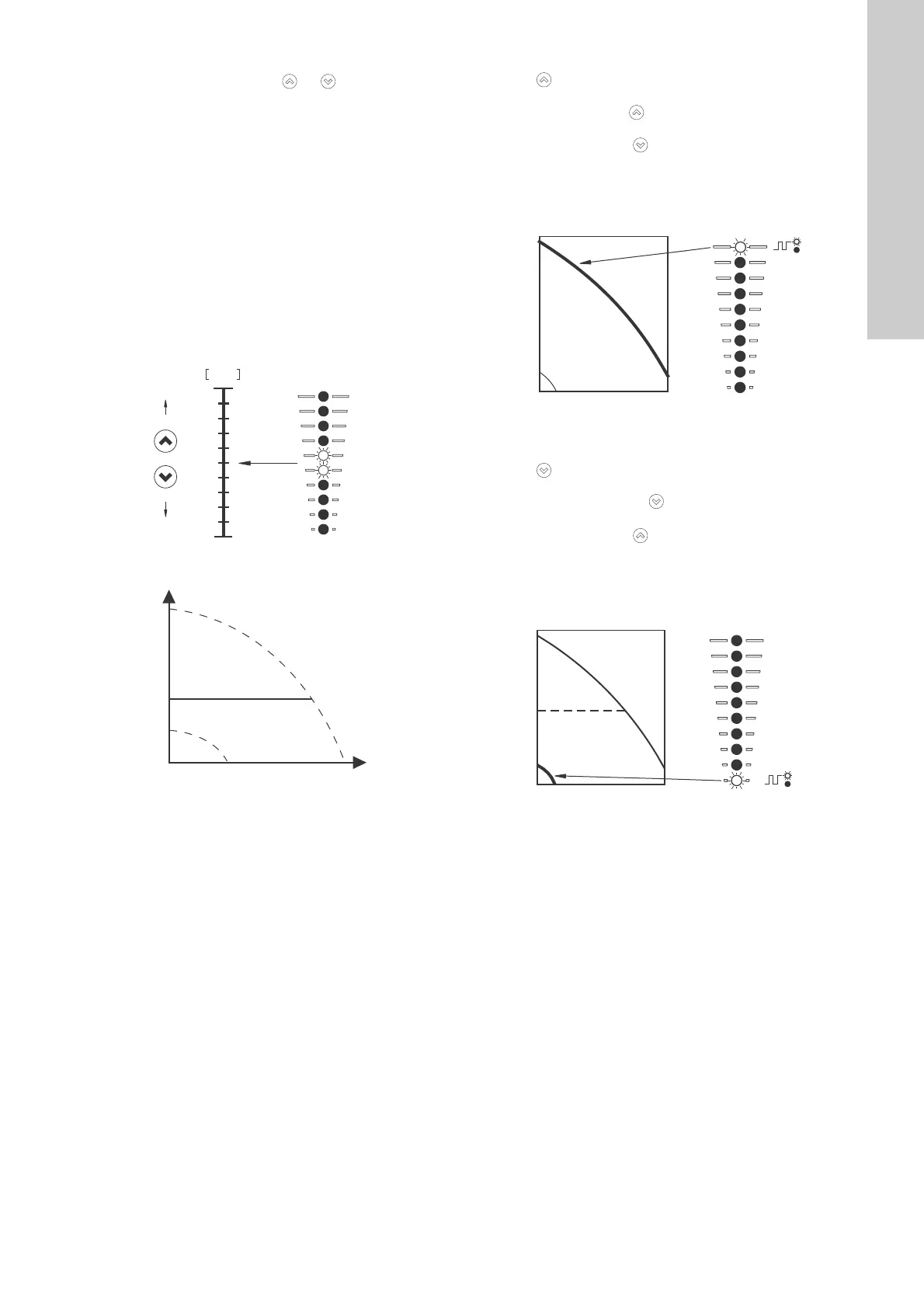

Setting to minimum curve:

• Press

continuously to change over to the minimum curve

of the pump (bottom light field flashes). When the bottom light

field is on, press and hold

for 3 seconds until the light field

starts flashing.

• To change back, press continuously until the desired

setpoint is indicated.

Example: Pump set to minimum curve.

Figure 32 shows that the bottom light field is flashing, indicating

minimum curve.

Fig. 32 Minimum curve duty

TM05 4894 3512TM05 7901 35122

TM05 4896 2812TM05 4897 2812

Loading...

Loading...