PHP A-1 Instruction Manual / Commissioning PHP A-1

6 Commissioning PHP A-1

28

STEP 4

Check the correctness of all hydraulic and electric

connections, especially expansion pressure pipe, expansion

overflow pipe and flow direction at the connection point in

system return.

STEP 5

Open the makeup water connection to EMCF-1 V makeup

module and set the pressure reducing valve to 1,5 bar -

max. 2,0 bar.

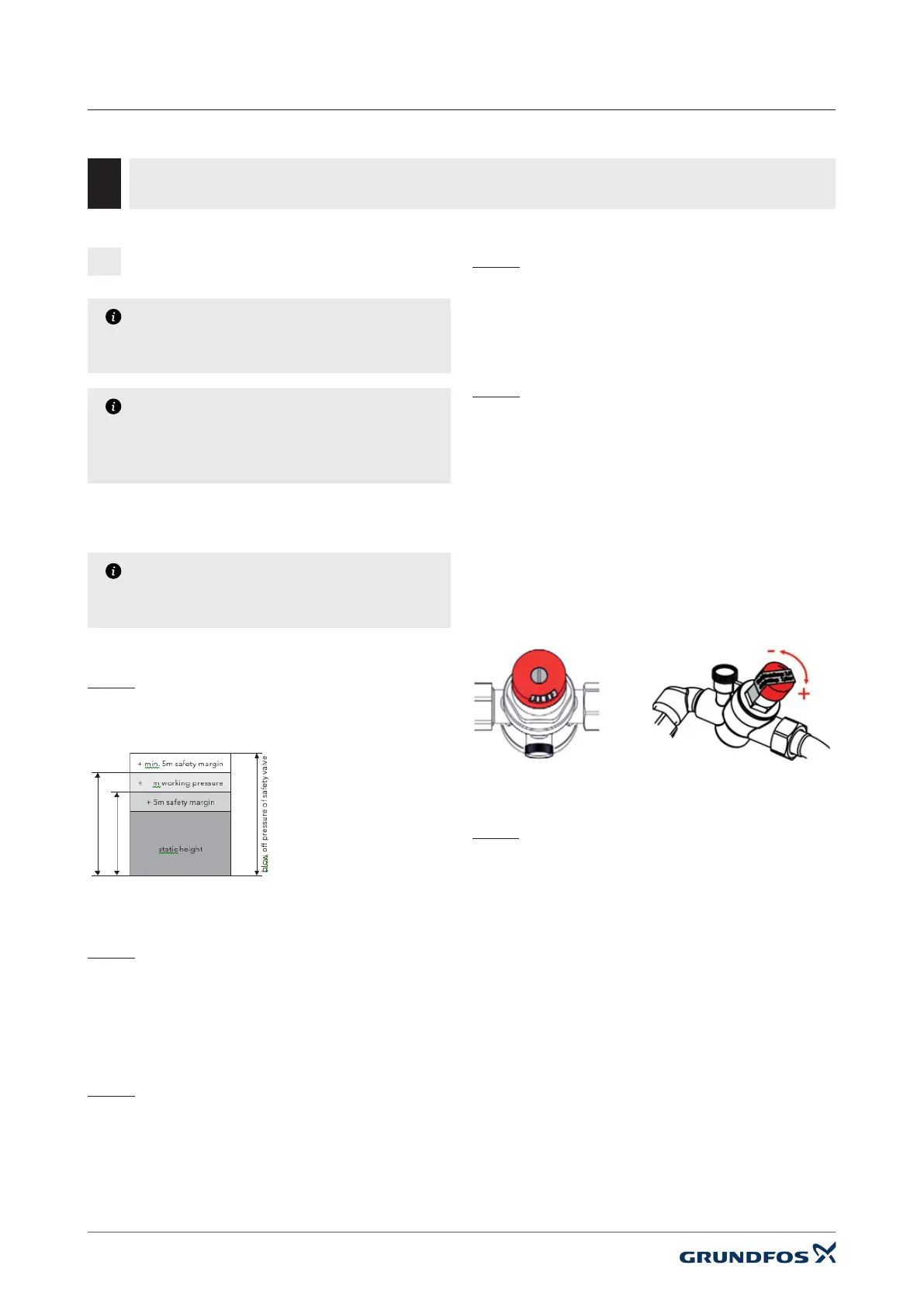

Version A:

Loosen the screw (1) at the pressure reducing valve and set

the scale to 1,5 bar - max. 2,0 bar. To fix the setting, the

screw must be tightened again.

Version B:

Set the pressure at the setting knob (2). If the Break tank

mounted ex factory, the pressure is already set, see sealing

sticker at the valve (3).

STEP 6

Switch on power supply and check if the red control lamp

beside the key “0” glows. If not, deactivate the device by

pressing the key “0” and following confirmation by pressing

the key “F1” (red control lamp beside the key “0” must glow).

Version BVersion A

1

2

3

Commissioning procedure:

STEP 1

Determine the upper working pressure. This upper working

pressure is also the set pressure of the overflow valve.

STEP 2

Shut all connections from/to system return (expansion

overflow pipe, expansion pressure pipe, makeup water)

CAUTION: Do NOT shut suction pipe and overflow pipe at

EMCM series.

STEP 3

Fill and ventilate the system to the upper working pressure

as determined in Step 1.

NOTE

Steps 1-3 must be completed on site in preparation for

the commissioning.

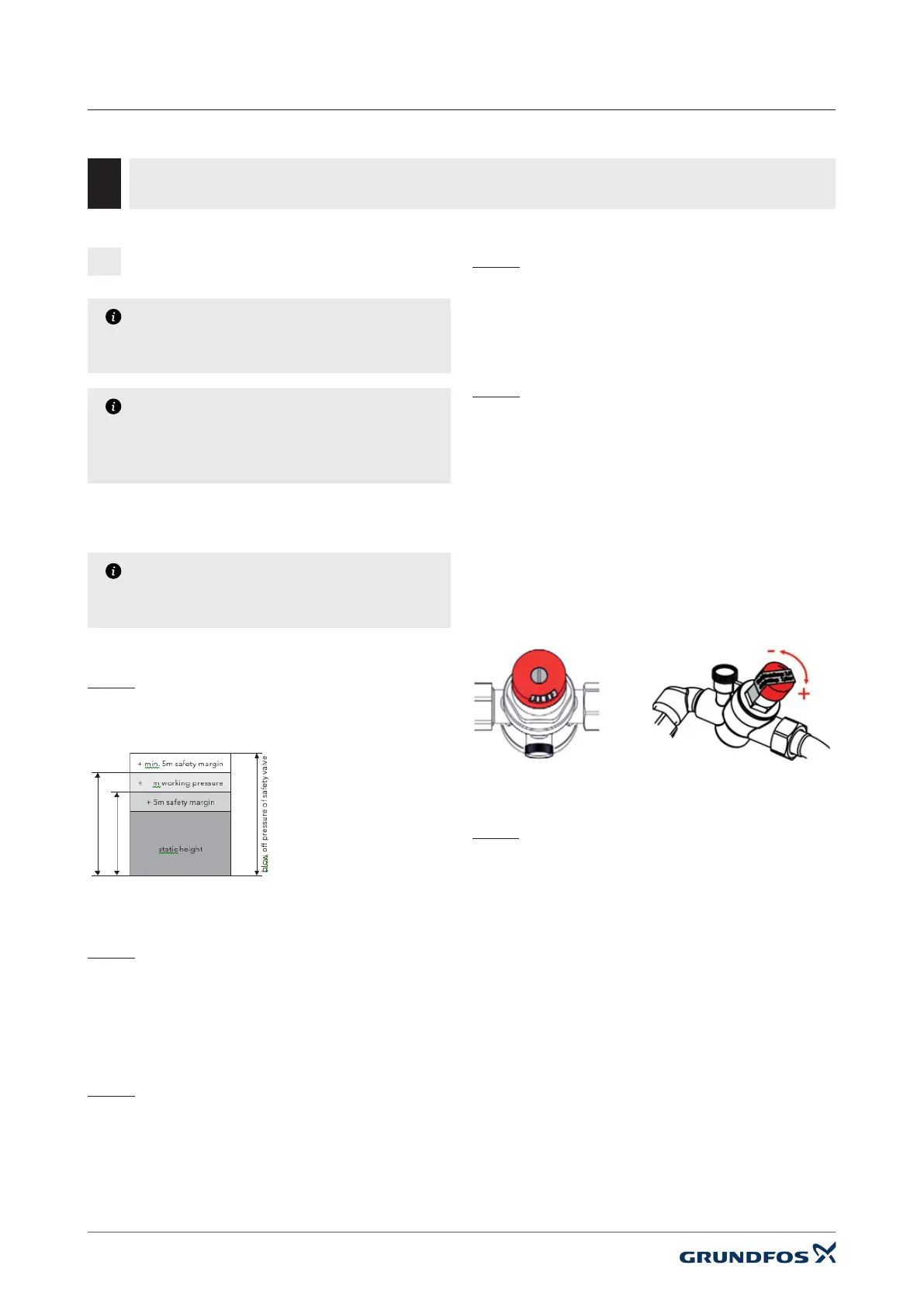

Figure: determination of the upper and lower working pressure

10m Ws~1 bar

INFORMATION

For modular PHP 4-9 series devices see the instruction

manual PHP 4-9, chapter “Commissioning”

NOTE

Commissioning by the Spirotech customer service resp.

and authorised partner and training of the operating

personnel is recommended.

6.1 Commissioning PHP

Loading...

Loading...