PHP A-1 Instruction Manual / Hazard notes

11 Hazard notes

48

WARNING

Workings at the device only may be done by a trained

and authorised expert. Disconnect power supply before

working at the device.

Due to the design of the PHP pressure maintenance device

there are only marginal hazards.

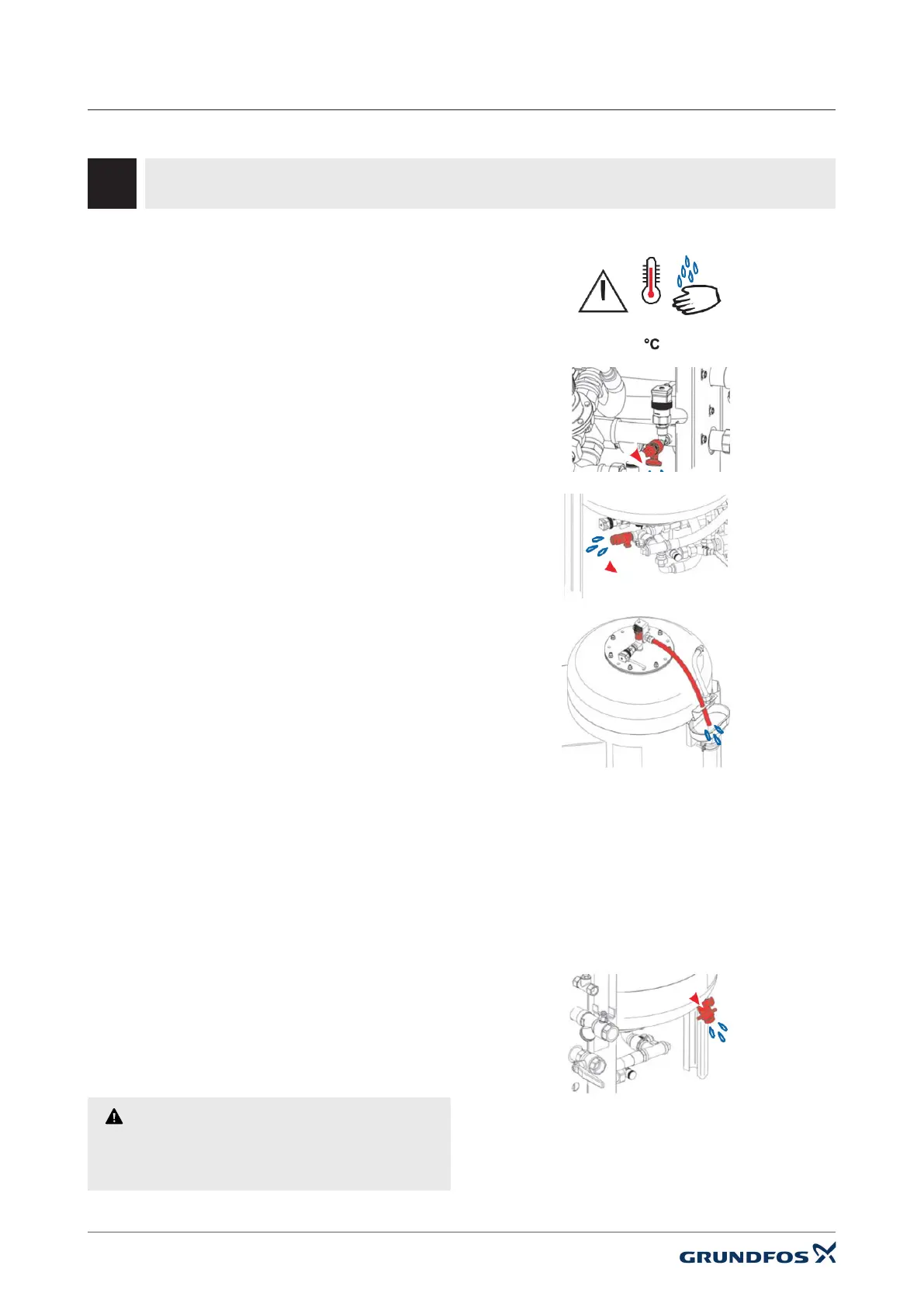

Generally you have to keep in mind, that hot plant

media (e.g. heating water) could leak due to handling

at these devices.

For service and maintenance purposes a fill and drain tap

is provided at kompakt EMCK and modular PHP series

devices. Hot plant media could leak from this tap too.

Scalding risk exists in case of leakage.

Another fill and drain tap is installed at the lower vessel

flange (only at kompakt EMCK series) of the built-on vessel.

This tap is for service and maintenance purposes. If this tap

is opened, hot plant media could leak too.

Scalding risk exists in case of leakage.

A safety valve 0,5 bar is installed at the upper vessel flange.

This valve could open and discharge hot plant media due to

the following reasons:

• The device resp. the expansion vessel was dimensioned

wrong (too small) and the entire expansion volume can‘t

be stored in the expansion vessel.

• The level measurement doesn‘t work correctly due to

defective vessel pressure transmitters or a defective

vessel membrane. So the vessel could get overfilled.

• The vessel has been filled to a too high level in cold

situation (eventually because of the function “one-time

filling” or uncontrolled if no makeup module EMCF-1 V is

installed) without taking care of the occurring expansion

volume. So this expansion volume can‘t be stored

completely in the expansion vessel.

Scalding risk exists in case of leagage.

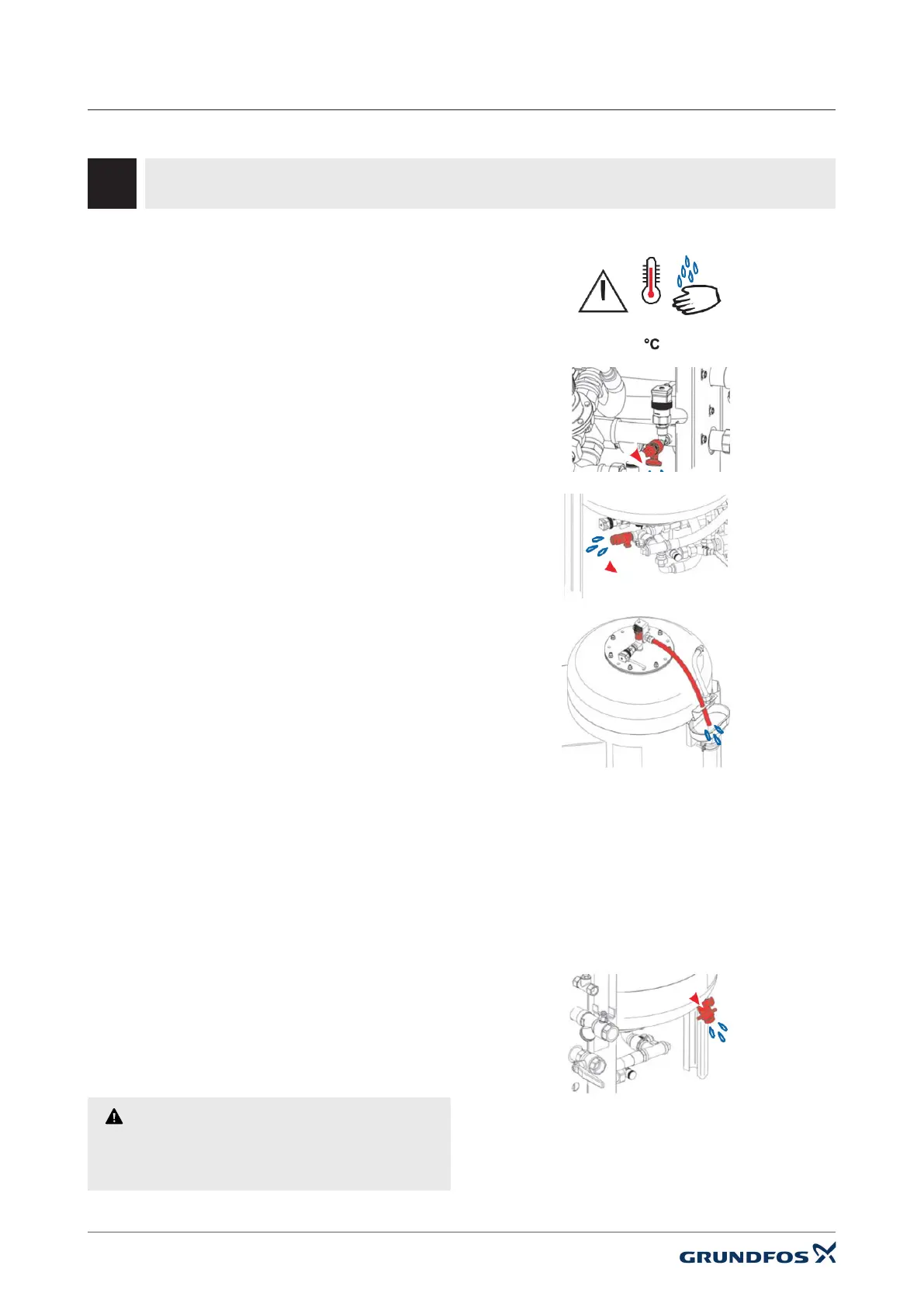

A further fill and drain tap is installed at the bottom of the

vessel. In normal operation there are no expected hazards

based on this tap. If the built-in vessel membrane is

defective, hot plant media could leak from this tap.

Scalding risk exists in case of leakage.

Loading...

Loading...