DANGER

Crushing hazard

Death or serious personal injury

‐ When lifting the pump, make sure the

centre of gravity is between the forklift

arms. The approximate centre of gravi-

ty is marked with a label attached to

the transport stand.

DANGER

Electric shock

Death or serious personal injury

‐ Never lift the pump by the power sup-

ply cables.

Lifting the pump by the power supply cables may

cause an electric short circuit and electric shock when

the pump is connected to the mains. The cables and

cable entries may be damaged, resulting in loss of

water resistance and consequent severe damage to

the motor.

If the pump is tilted more than 10° in any direction

from its normal position (EN 809), the pump may lose

its stability.

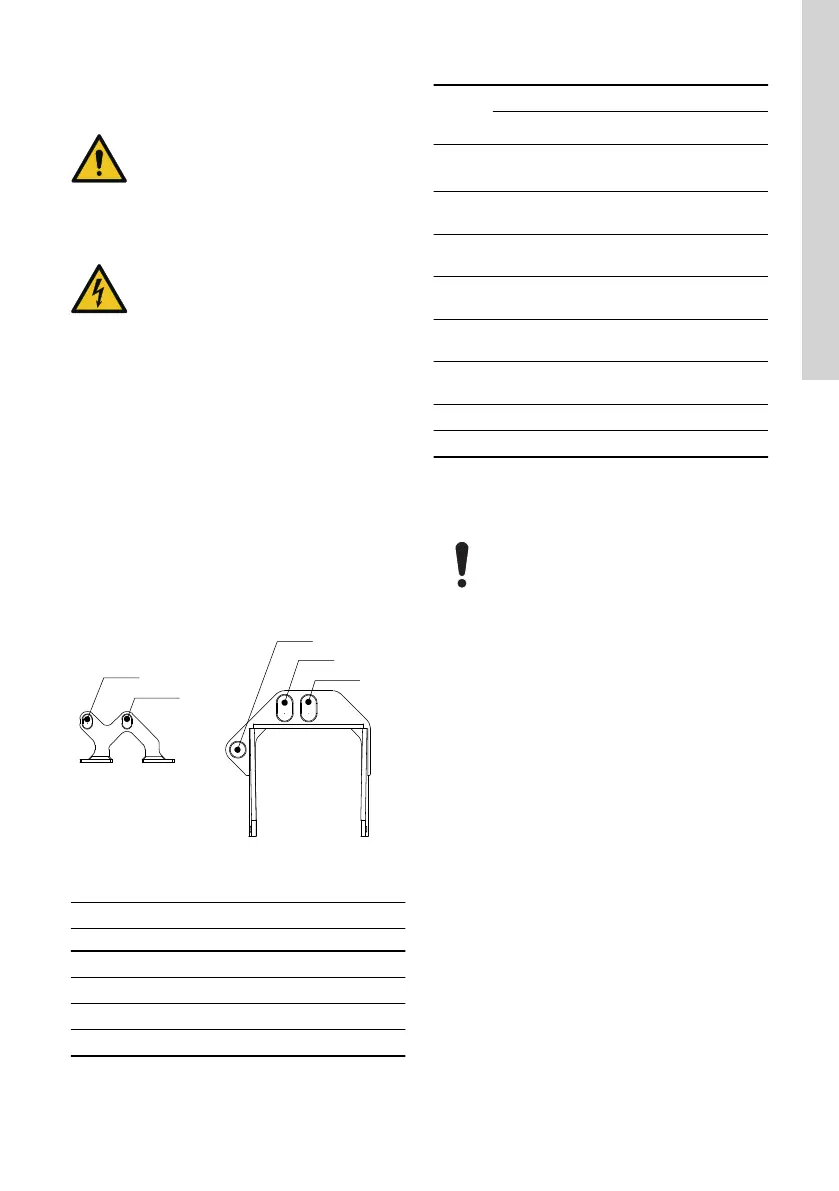

Lifting points (top)

S pumps are equipped with a lifting bracket with lifting

points. Use the right lifting point to keep the pump

balanced. See fig. Lifting points for installation types

S, C and D* and the table below for the correct lifting

points.

TM047173

Lifting points for installation types S, C and D*

Range 50 and 54 Range 58, 62, 66 and 70

Pos. Description

F Front

M Middle

N Nose

Outlet

flange

size

Pump range

50 54 58 62 66 70

DN

80

Mid-

dle

Mid-

dle

- - - -

DN 100

Mid-

dle

Mid-

dle

- - - -

DN 125

Mid-

dle

Mid-

dle

Mid-

dle

Mid-

dle

- -

DN 200 Front Front Front

Mid-

dle

Mid-

dle

Mid-

dle

DN 250 - Front - -

Mid-

dle

Mid-

dle

DN 300 - - Front

Mid-

dle

Mid-

dle

Mid-

dle

DN 500 - - - - Nose Front

DN 600 - - - - Nose Front

* The design of the lifting bracket may differ from the

one in the drawing. This difference does not affect the

handling of the product.

Always lift installation type ST pumps in

the middle lifting point to make sure the

pump is balanced.

Related information

2.4.2 Nameplate

10.3 Dimensions and weights

13

English (GB)

Loading...

Loading...