English (GB)

13

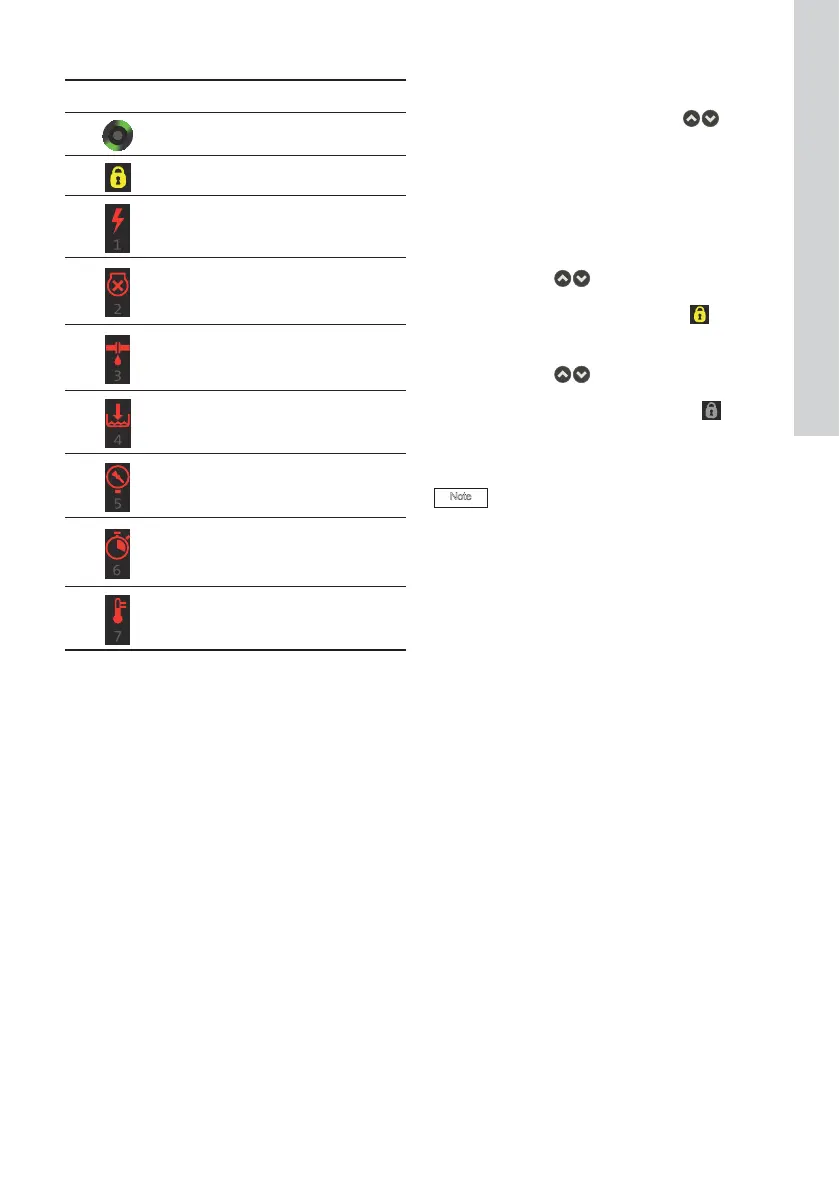

7.1.2 Indicator lights, SCALA2

* For fault number 4, dry-running, the pump must

be reset manually. For fault number 4, water

shortage, and the remaining faults, 1, 2, 3, 5, 6

and 7, the pump will reset whenever the cause

has disappeared or been remedied. See section

8.3.2 Auto reset.

For further information about system status, see

section 12.1 Grundfos Eye operating indications.

8. Operating the controller

8.1 Setting the outlet pressure

Adjust the outlet pressure by pressing .

8.2 Locking and unlocking the operating

panel

The operating panel can be locked, which means

that the buttons do not function and no settings can

be changed accidentally.

How to lock the operating panel

1. Hold down the buttons simultaneously for

three seconds.

2. The operating panel is locked when symbol

lights up.

How to unlock the operating panel

1. Hold down the buttons simultaneously for

three seconds.

2. The operating panel is unlocked when symbol

turns off.

8.3 Expert settings, SCALA2

The expert setting menu allows the installer to toggle

between the functions "Auto reset", "Anti cycling"

and "Maximum continuous operating time".

Indications Description

Operating indications

The operating panel is locked

Power supply failure

The pump is blocked, e.g. the

shaft seal has seized up

Leakage in the system

Dry-running or water shortage*

The maximum pressure has been

exceeded or the setpoint cannot

be reached

The maximum runtime has been

exceeded

The temperature is outside the

range

Expert settings are for installers only.

Loading...

Loading...