English (GB)

14

8.2 Operation

8.2.1 Minimum flow rate

To ensure the necessary cooling of the motor, the pump flow rate

should never be set so low that the cooling requirements in

section 5.4 Liquid temperatures/cooling cannot be met.

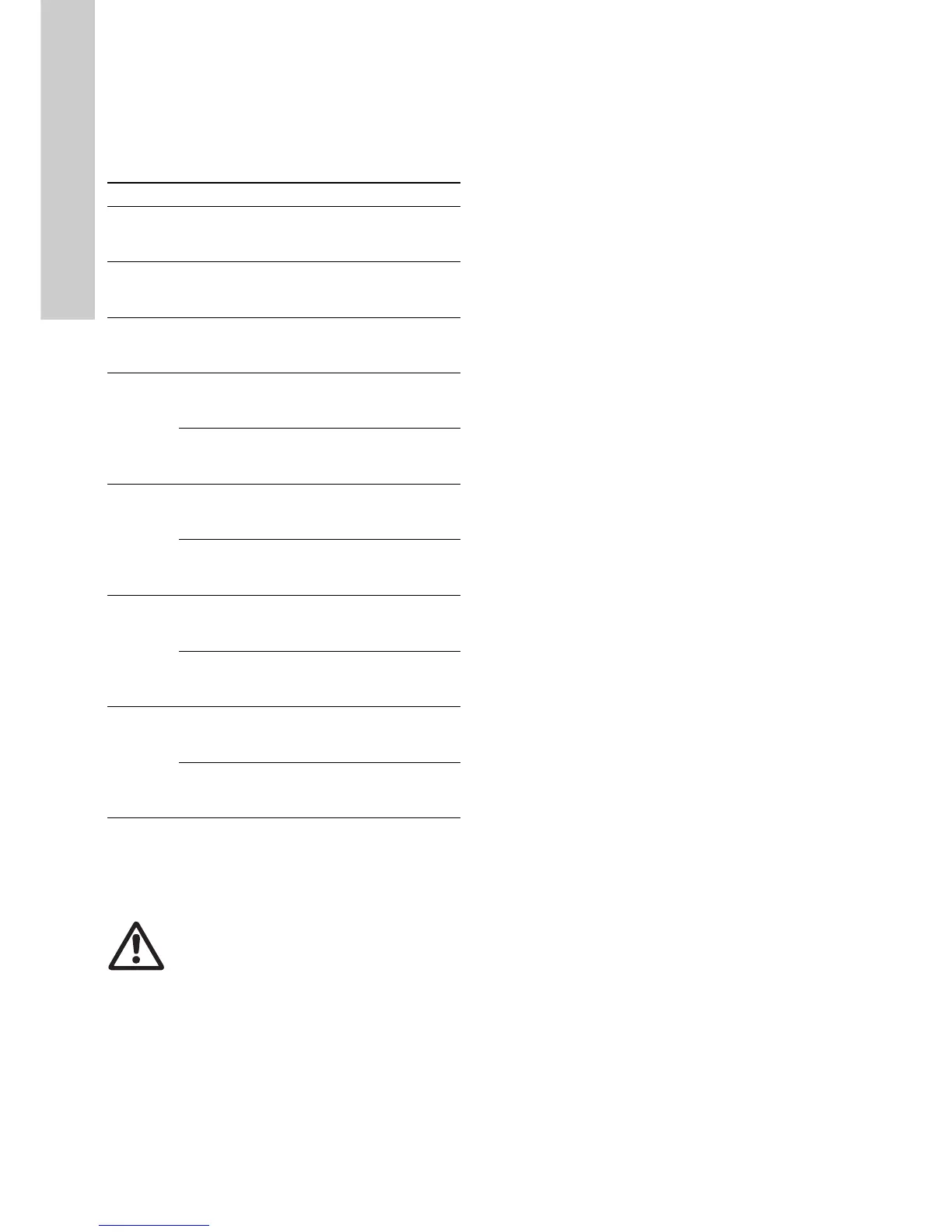

8.2.2 Frequency of starts and stops

9. Maintenance and service

All pumps are easy to service.

Service kits and service tools are available from Grundfos.

The pumps can be serviced at a Grundfos service centre.

If Grundfos is requested to service the pump, Grundfos must be

contacted with details about the pumped liquid, etc. before the

pump is returned for service. Otherwise Grundfos can refuse to

accept the pump for service.

Possible costs of returning the pump are paid by the customer.

Motor type Number of starts

MS 402

• Minimum 1 per year is

recommended.

• Maximum 100 per hour.

• Maximum 300 per day.

MS 4000

• Minimum 1 per year is

recommended.

• Maximum 100 per hour.

• Maximum 300 per day.

MS 6000

• Minimum 1 per year is

recommended.

• Maximum 30 per hour.

• Maximum 300 per day.

MMS6

PVC windings

• Minimum 1 per year is

recommended.

• Maximum 3 per hour.

• Maximum 40 per day.

PE/PA windings

• Minimum 1 per year is

recommended.

• Maximum 10 per hour.

• Maximum 70 per day.

MMS 8000

PVC windings

• Minimum 1 per year is

recommended.

• Maximum 3 per hour.

• Maximum 30 per day.

PE/PA windings

• Minimum 1 per year is

recommended.

• Maximum 8 per hour.

• Maximum 60 per day.

MMS 10000

PVC windings

• Minimum 1 per year is

recommended.

• Maximum 2 per hour.

• Maximum 20 per day.

PE/PA windings

• Minimum 1 per year is

recommended.

• Maximum 6 per hour.

• Maximum 50 per day.

MMS 12000

PVC windings

• Minimum 1 per year is

recommended.

• Maximum 2 per hour.

• Maximum 15 per day.

PE/PA windings

• Minimum 1 per year is

recommended.

• Maximum 5 per hour.

• Maximum 40 per day.

Warning

If a pump has been used for a liquid which is

injurious to health or toxic, the pump will be classified

as contaminated.

Loading...

Loading...