English (GB)

6

5.4.1 Maximum liquid temperature

Out of consideration for the rubber parts in pump and motor, the

liquid temperature must not exceed 40 °C (~ 105 °F). See also

the table below.

The pump can operate at liquid temperatures between 40 °C and

60 °C (~ 105 °F and 140 °F) provided that all rubber parts are

replaced every third year.

5.5 Pipe connection

If noise may be transmitted to the building through the pipework,

we recommend that you use plastic pipes.

When using plastic pipes, secure the pump by an unloaded

straining wire.

When connecting plastic pipes, use a compression coupling

between the pump and the first pipe section.

6. Electrical connection

The supply voltage, rated maximum current and cos φ appear

from the loose data plate which must be fitted close to the

installation site.

The required voltage quality for MS and MMS motors, measured

at the motor terminals, is - 10 %/+ 6 % of the nominal voltage

during continuous operation (including variation in the supply

voltage and losses in cables).

Check also that there is voltage symmetry in the power supply

lines, i.e. same difference of voltage between the individual

phases. See section 11. Checking motor and cable, item 2.

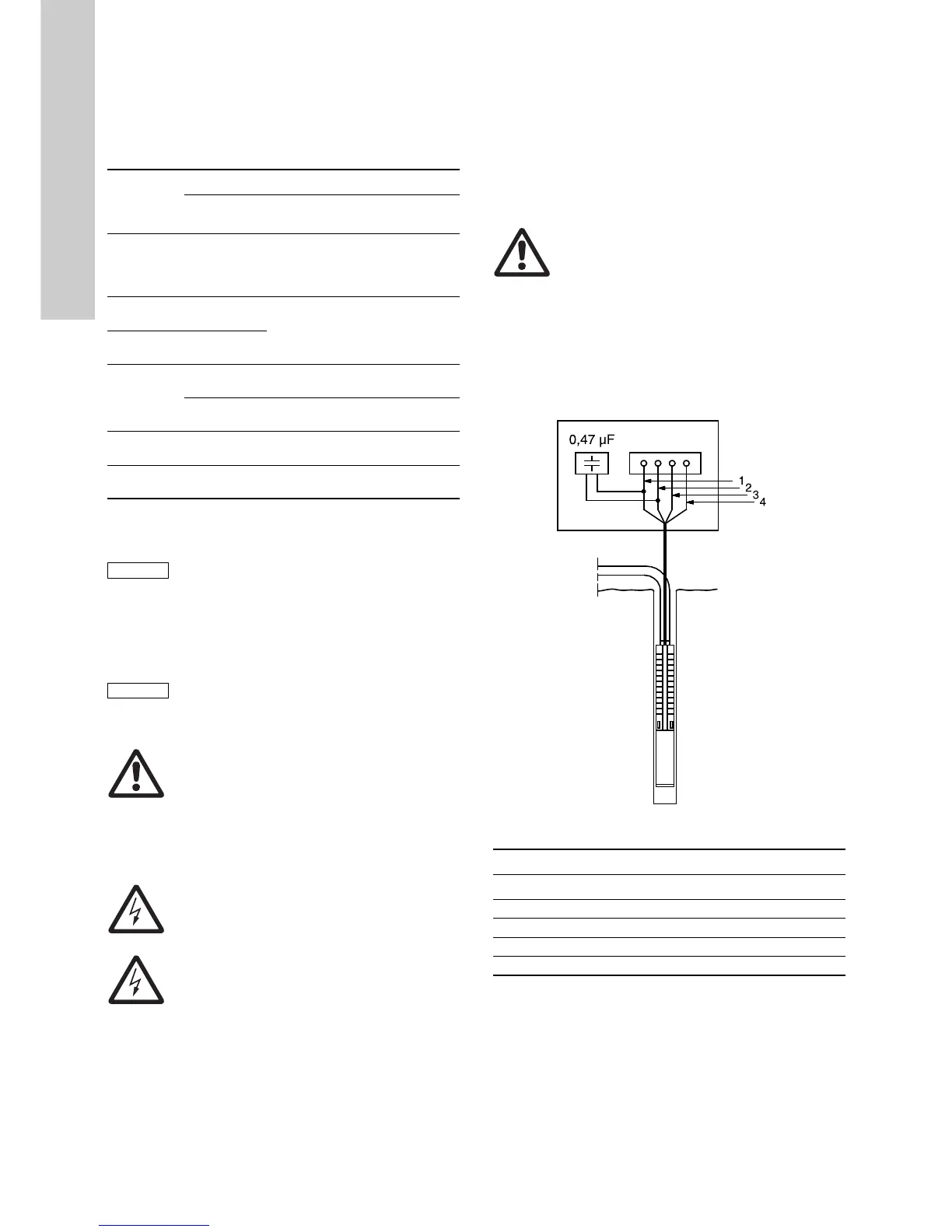

If MS motors with a built-in temperature transmitter (Tempcon)

are not installed together with a MP 204 or similar Grundfos

motor protection, they must be connected to a 0.47 μF capacitor

approved for phase-phase operation (IEC 384-14) to meet the EC

EMC directive (2004/108/EC). The capacitor must be connected

to the two phases to which the temperature transmitter is

connected. See fig. 9.

Fig. 9 Connection of capacitor

The motors are wound for direct-on-line starting or star-delta

starting, and the starting current is between four and six times the

rated current of the motor.

The run-up time of the pump is only about 0.1 second.

Direct-on-line starting is therefore normally approved by the

power supply company.

Motor

Installation

Flow past

the motor

Vertical Horizontal

Grundfos

MS 402

MS 4000

MS 6000

0.15 m/s

40 °C

(~ 105 °F)

40 °C

(~ 105 °F)

Grundfos

MS 4000I*

0,15 m/s

60 °C

(~ 140 °F)

Flow sleeve

recommended

60 °C

(~ 140 °F)

Flow sleeve

recommended

Grundfos

MS 6000I*

1.00 m/s

Grundfos

MMS

0.15 m/s

25 °C

(~ 77 °F)

25 °C

(~ 77 °F)

0.50 m/s

30 °C

(~ 86 °F)

30 °C

(~ 86 °F)

Franklin

4"

0.08 m/s

30 °C

(~ 85 °F)

30 °C

(~ 85 °F)

Franklin

6" and 8"

0.16 m/s

30 °C

(~ 85 °F)

30 °C

(~ 85 °F)

* At an ambient pressure of minimum 1 bar (1 MPa).

We recommend plastic pipes for 4" pumps only.

Warning

Make sure that the plastic pipes are suitable for the

actual liquid temperature and the pump pressure.

Warning

During electrical installation, make sure that the

power supply cannot be accidentally switched on.

Warning

The electrical installation should be carried out by an

authorised person in accordance with local

regulations.

Warning

The pump must be earthed.

The pump must be connected to an external mains

switch with a minimum contact gap of

3 mm in all poles.

TM00 7100 0696

Colours of the leads

Lead Flat cable Single leads

1 = L1 Brown Black

2 = L2 Black Yellow

3 = L3 Grey Red

4 = PE Yellow/green Green

Loading...

Loading...