Grundfos motors

All three-phase Grundfos motors from frame size 90

and up can be connected to a frequency converter.

The connection of a frequency converter will often

have the effect that the motor insulation system is

loaded more and that the motor will be more noisy

than during normal operation. In addition, large

motors are more at risk of being loaded with bearing

currents caused by the frequency converter.

Check these operating conditions if the pump is

driven via a frequency converter:

Operating conditions Action

2-pole motors from 45

kW, 4-pole motors from

37 kW and 6-pole motors

from 30 kW

Check that one of the

motor bearings is

electrically isolated.

Contact Grundfos.

Noise critical applications

Fit an output filter

between the motor and

the frequency converter;

this reduces the voltage

peaks and thus the

noise.

Particularly noise critical

applications

Fit a sinusoidal filter.

Cable length

Fit a cable that meets the

specifications laid down

by the frequency

converter supplier. The

length of the cable

between motor and

frequency converter

affects the motor load.

Supply voltage up to 500

V

Check that the motor is

suitable for frequency

converter operation.

Supply voltage between

500 V and 690 V

Fit a sinusoidal filter

between the motor and

the frequency converter

which reduces the

voltage peaks and thus

the noise, or check that

the motor has reinforced

insulation.

Supply voltage of 690 V

and higher

Fit a sinusoidal filter and

check that the motor has

reinforced insulation.

Grundfos MG motors do not have

reinforced insulation. When it comes to

reinforced insulation, other motors

supplies are able to supply such motors as

FPV variants.

Other motor makes than Grundfos

Contact Grundfos or the motor manufacturer.

4.4.3

Synchronous motors

Pumps fitted with synchronous motors must be

connected to a Grundfos CUE frequency converter.

TM044289

Example of installation without filter

Symbol Designation

1 CUE

4 Standard motor

One line Unscreened cable

Double line Screened cable

Synchronous motors must not be

connected directly to mains supply.

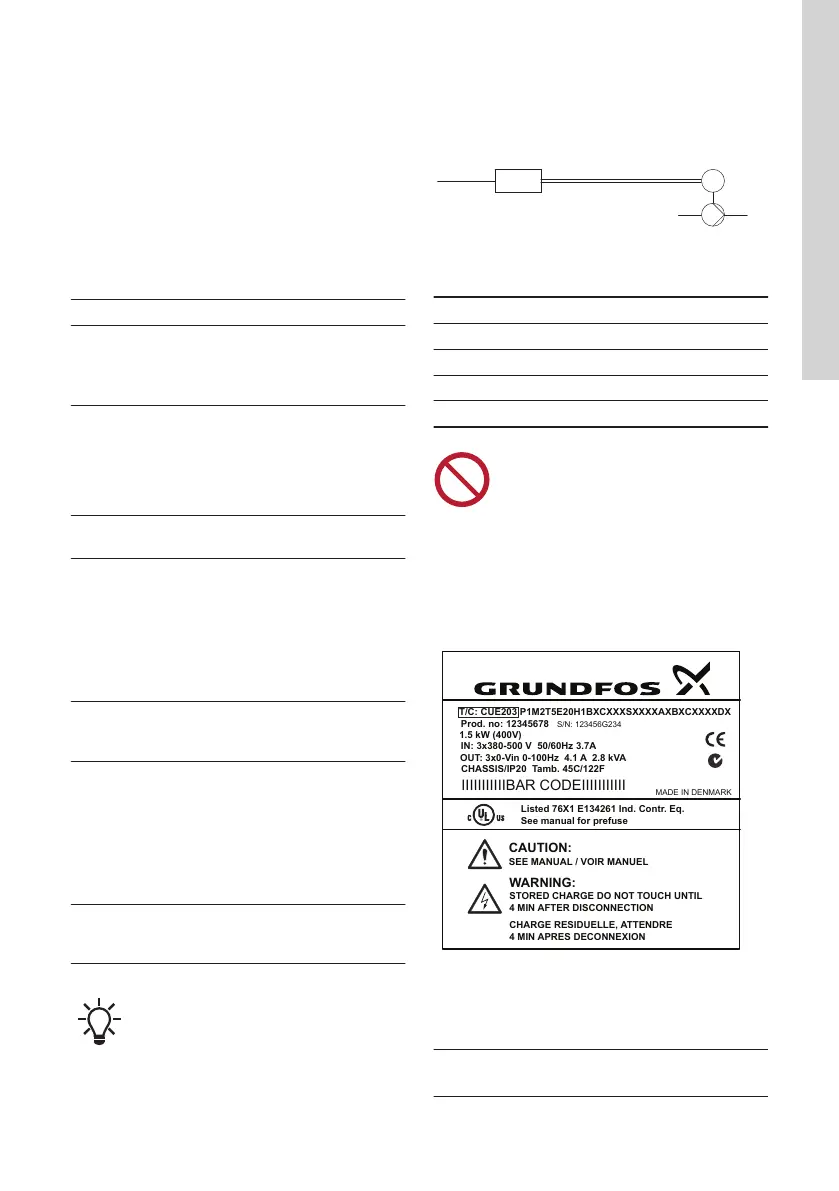

The CUE must be of T/C CUE203 followed by

additional numbers and characters. See the CUE

Installation and operating instruction to setup

frequency driver together with synchronous motor.

If another frequency driver brand other than CUE is

required or specified, contact Grundfos.

T/C: CUE203 P1M2T5E20H1BXCXXXSXXXXAXBXCXXXXDX

IN: 3x380-500 V 50/60Hz 3.7A

OUT: 3x0-Vin 0-100Hz 4.1 A 2.8 kVA

CHASSIS/IP20 Tamb. 45C/122F

IIIIIIIIIIIBAR CODEIIIIIIIIIII

Listed 76X1 E134261 Ind. Contr. Eq.

STORED CHARGE DO NOT TOUCH UNTIL

TM077181

Example of CUE nameplate

Text Description

T/C

CUE: product name

203... :internal code

17

English (GB)

Loading...

Loading...