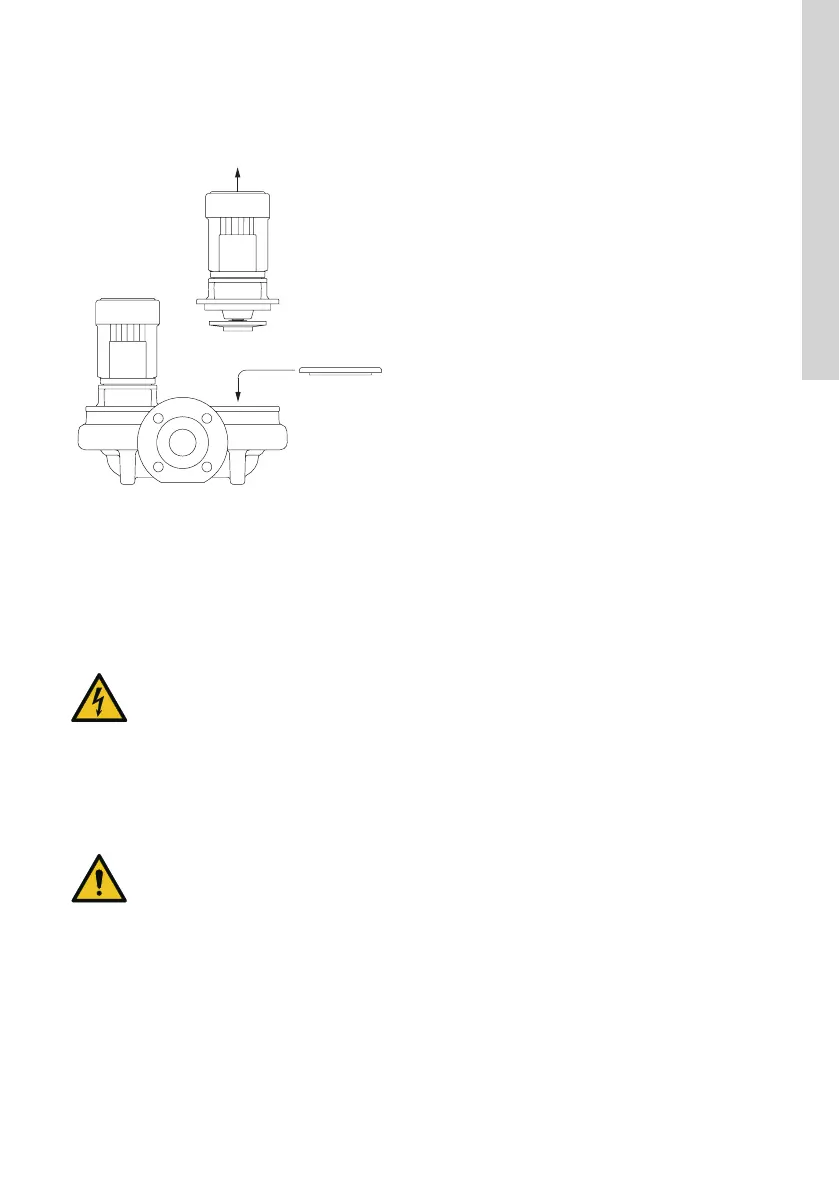

7.3 Blanking flanges

For twin-head pumps, a blanking flange with a pump

housing gasket is available. See the figure below.

TM006360

Fitting the blanking flange

If one pump requires service, the blanking flange is

fitted to allow the other pump to continue operating.

7.4 Maintaining the product

DANGER

Electric shock

Death or serious personal injury

‐ Before starting any work on the

product, make sure that the power

supply has been switched off and that

it cannot be accidentally switched on.

WARNING

Escaping liquid

Death or serious personal injury

‐ Make sure that the escaping liquid

does not cause injury to persons or

damage to the motor or other

components. In hot-liquid installations,

pay special attention to the risk of

injury caused by scalding hot liquid. In

cold-liquid installations, pay special

attention to the risk of injury caused by

the cold liquid.

7.4.1 Pump

The pump is maintenance-free.

If the pump is to be drained for a long period of

inactivity, inject a few drops of silicone oil on the shaft

between the motor stool and the coupling. This will

prevent the shaft seal faces from sticking.

TP 25-50/2, 25-80/2, 25-90/2, 32-50/2, 32-80/2,

32-90/2, 40-50/2, 40-80/2 and 40-90/2 must be

operated minimum once every month in minimum 5

minutes to prevent the shaft seal faces from sticking.

7.4.2 Motor

The motor must be checked at regular intervals. It is

important to keep the motor clean in order to ensure

adequate ventilation. If the pump is installed in a

dusty environment, both pump and motor must be

cleaned and checked regularly.

7.4.3 Lubrication

MG motors

The bearings of motors up to 11 kW are greased for

life and require no lubrication.

The bearings of motors of 11 kW and up must be

greased in accordance with the indications on the

motor nameplate.

Siemens motors

Motors up to and including frame size 250 have

maintenance-free, greased-for-life bearings.

Motors of frame sizes larger than 250 must be

greased according to the indications on the motor

nameplate. Grease spills from the motor may occur.

Other motors

For other motor makes with grease nipples, lubricate

the motor according to the indications on the motor

nameplate.

7.4.4 Bearing grease

The motor must be lubricated with a lithium-based,

high-temperature grease.

• The technical specification of the grease must

correspond to DIN 51825, K3N, or better.

• The viscosity of the basic oil must be higher than

50 cSt (mm

2

/s) at 40 °C (104 °F) and 8 cSt

(mm

2

/s) at 100 °C (212 °F).

• The grease filling rate must be 30-40 %.

7.4.5

Frost protection

Pumps which are not being used during periods of

frost must be drained to avoid damage.

21

English (GB)

Loading...

Loading...