5. Starting up the product

5.1 Flushing the pipe system

CAUTION

Biological hazard

Minor or moderate personal injury

‐ When pumping drinking water, the

pump must be flushed thoroughly with

clean water before startup in order to

remove any foreign matters, such as

preservatives, test liquid, or grease.

• Before starting up the pump, thoroughly clean,

flush and fill the pipe system with clean water.

The warranty does not cover any

damage caused by flushing the pipe

system by means of the pump.

The pump is not designed to pump

liquids containing solid particles such

as pipe debris and welding slag.

5.2 Priming

Always fill and vent the pump before

starting the pump. To ensure correct

venting, the vent screw must point

upwards.

5.2.1 Priming the product in closed systems or

open systems where the liquid level is above

the pump inlet

WARNING

Escaping liquid

Death or serious personal injury

‐ Pay attention to the orientation of the

vent hole to ensure that the escaping

liquid does not cause personal injury or

damage to the motor or other

components.

‐ In hot-liquid installations, pay special

attention to the risk of personal injury

caused by scalding hot liquid.

‐ In cold-liquid installations, pay special

attention to the risk of personal injury

caused by cold liquid.

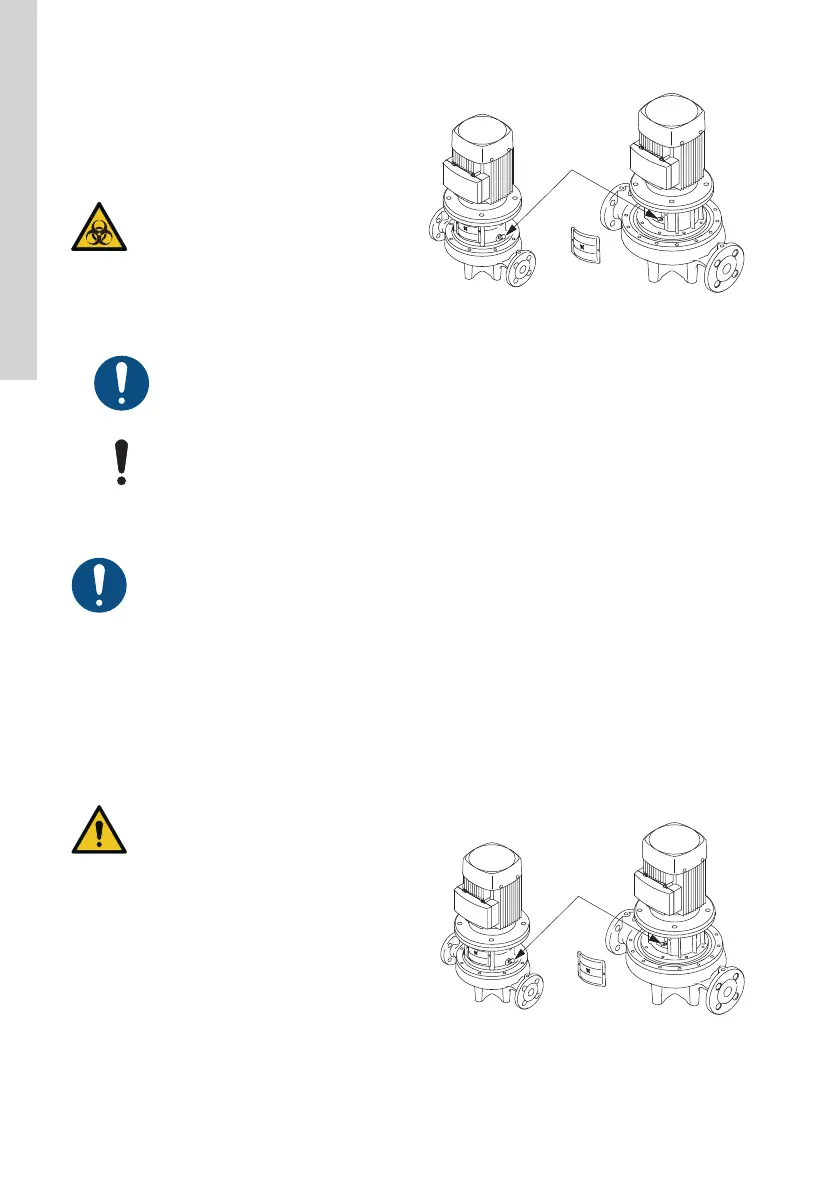

1. Close the isolating valve on the outlet side and

loosen the vent screw in the motor stool.

TM038126

Position of vent screw

2. Slowly open the isolating valve on the inlet side

until a steady stream of liquid runs out of the vent

hole.

3. Tighten the vent screw and completely open the

isolating valve(s).

5.2.2 Priming the product in open systems where

the liquid level is below the pump inlet

The inlet pipe and the pump must be filled with liquid

and vented before the pump is started.

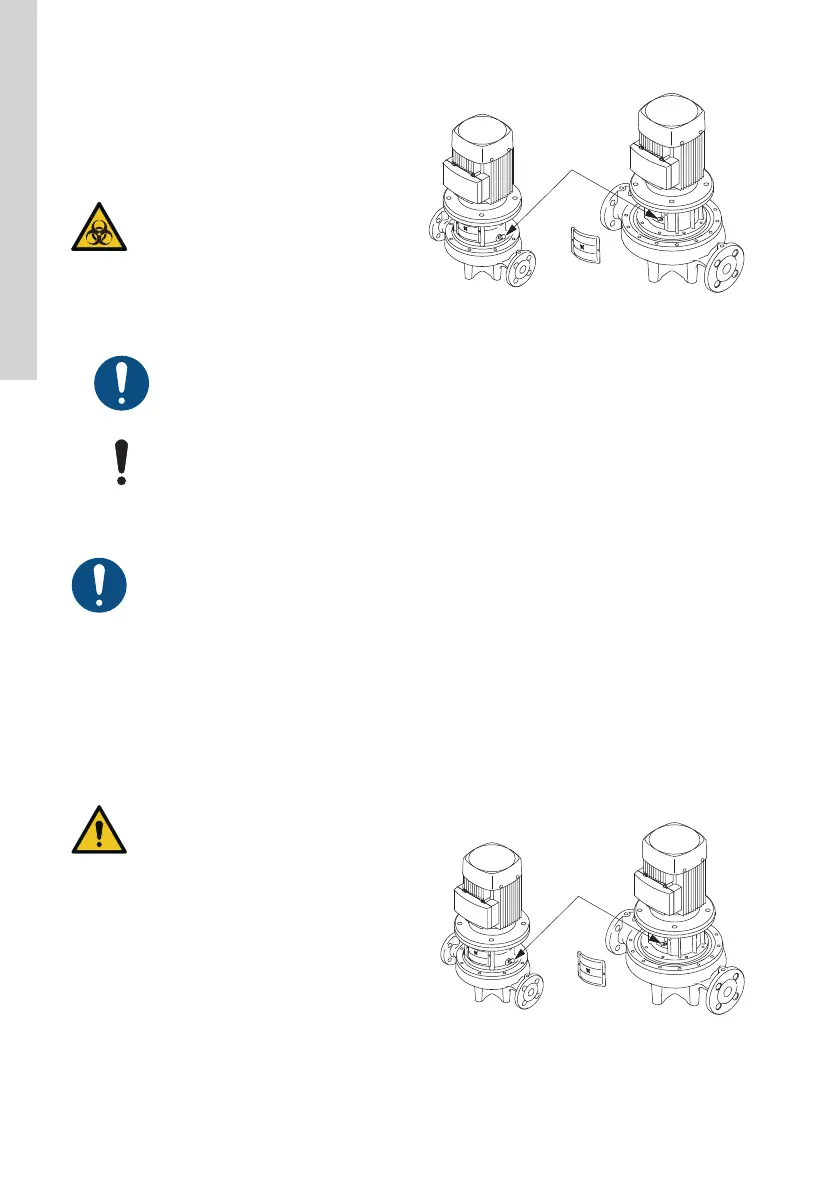

1. Close the isolating valve on the outlet side and

open the isolating valve on the inlet side.

2. Loosen the vent screw.

3. Remove the plug from one of the pump flanges,

depending on the pump location.

4. Pour liquid through the priming hole until the inlet

pipe and the pump are filled with liquid.

5. Replace the plug and tighten securely.

6. Tighten the vent screw.

The inlet pipe can to some extent be filled with liquid

and vented before it is connected to the pump. A

priming device can also be installed before the pump.

TM038126

Position of vent screw

18

English (GB)

Loading...

Loading...