Make sure that the corrosion inhibitor used does not

affect the rubber parts with which it comes into

contact.

Commercially available preservatives can be used for

this purpose. Please observe the manufacturer’s

instructions for application or removal.

To prevent water, dust, etc. from entering the pump,

keep all openings covered until the pipes are to be

fitted. The cost of having to dismantle the pump

during startup to remove foreign objects can be very

high.

7. Servicing the product

7.1 Contaminated products

CAUTION

Biological hazard

Minor or moderate personal injury

‐ Flush the pump thoroughly with clean

water and rinse the pump parts in

water after dismantling.

The product will be classified as contaminated if it has

been used for a liquid which is toxic or injurious to

health.

If you request Grundfos to service the product,

contact Grundfos with details about the liquid before

returning the product for service. Otherwise, Grundfos

can refuse to accept the product for service.

The product must be cleaned thoroughly before you

return it.

Costs of returning the product are to be paid by the

customer.

7.2

Adjusting the shaft

If the motor has been removed during installation or

for repair of the pump, the pump shaft must be

adjusted after the motor has been replaced.

7.2.1

Adjusting the shaft for pumps with two-part

coupling, TP Series 100 and 200

Make sure that the shaft pin is fitted in the pump

shaft.

Adjust the pump shaft as follows:

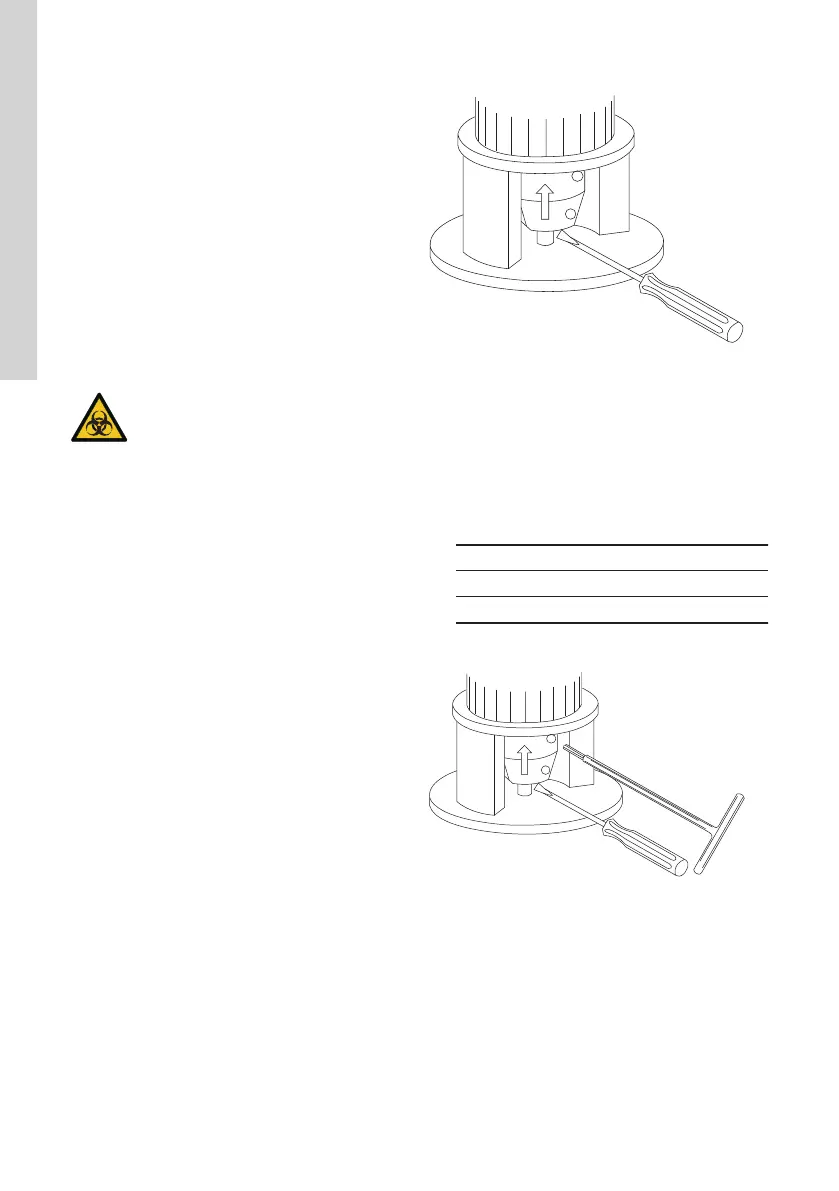

1. Remove the coupling guards using a screwdriver.

2. Fit the hexagon socket head screws in the

coupling and leave loose.

3. Raise the coupling and the pump shaft as far as

possible (towards the motor) with a screwdriver or

a similar tool so that the pump and motor shafts

touch each other.

TM006415

Raising the coupling and the pump shaft

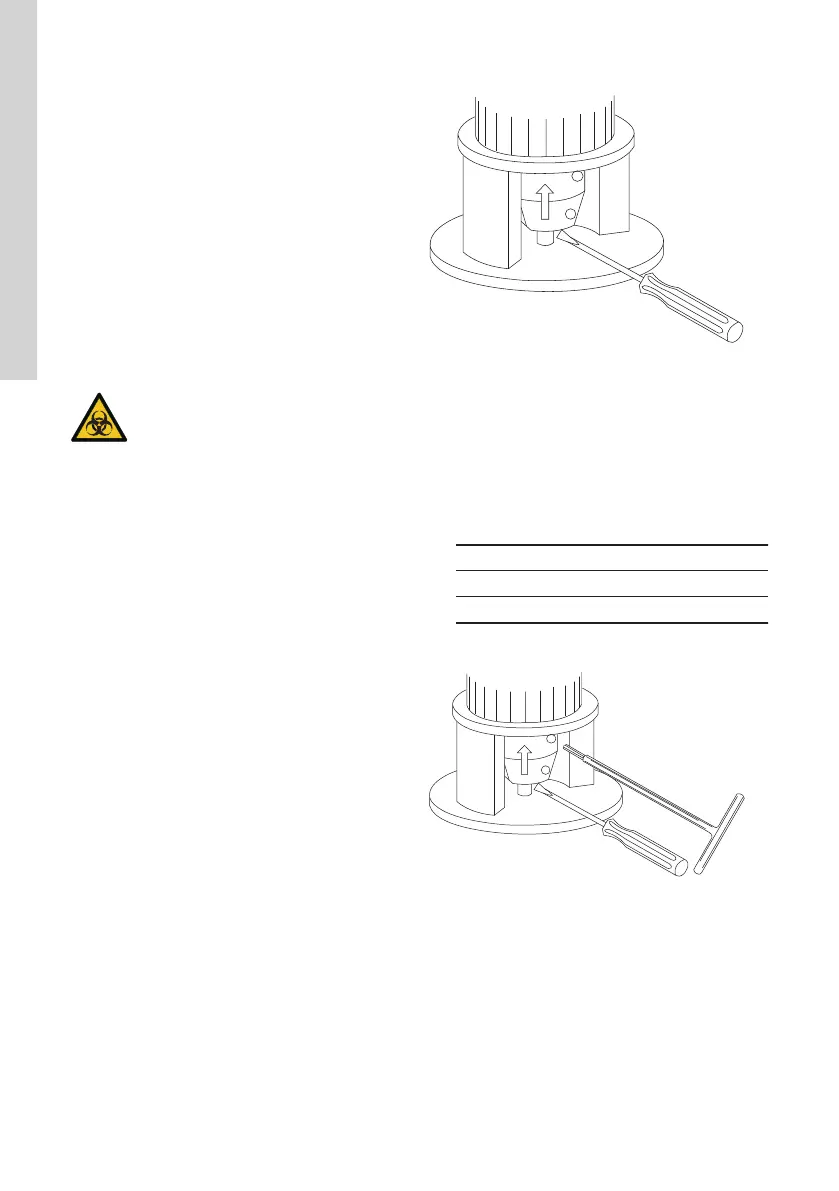

4. Tighten the hexagon socket head screws in the

coupling to 5 Nm (0.5 kpm).

5. Check that the gaps either side of the coupling

halves are equal.

6. Tighten the screws two and two (one side at a

time) to the torque stated below.

Hexagon socket head screw Torque

M6 x 20 13 Nm (1.3 kpm)

M8 x 25 31 Nm (3.1 kpm)

7. Fit the coupling guards.

TM006416

Tightening the screws

7.2.2 Pumps with integral shaft and coupling

For pumps with integral shaft and coupling, we

recommend that you do not remove the motor. If the

motor has been removed, it is necessary to remove

the motor stool in order to refit the motor correctly.

Otherwise, the shaft seal may be damaged.

20

English (GB)

Loading...

Loading...