22

PREPARATION FOR SELF PROPELLED OPERATION

The Gullco KBM

®

-18 Plate Edge Bevelling Machine is typically used with the optional spring loaded

caster Undercarriage Assembly, enabling self propelled operation. I.e. the material stays stationary

while the bevelling machine propels itself down its edge. This system is employed for bevelling

large and heavy plate materials which cannot be fed through the machine. When both the machine

and material are properly set up, as described below, the cutter will drive the machine on its caster

mount, along a floor or runway.

Plate materials should be secured on a work table/platform that is of an appropriate height above

the floor, or runway, for the angle of bevel to be performed. See the table below for minimum plate

heights.

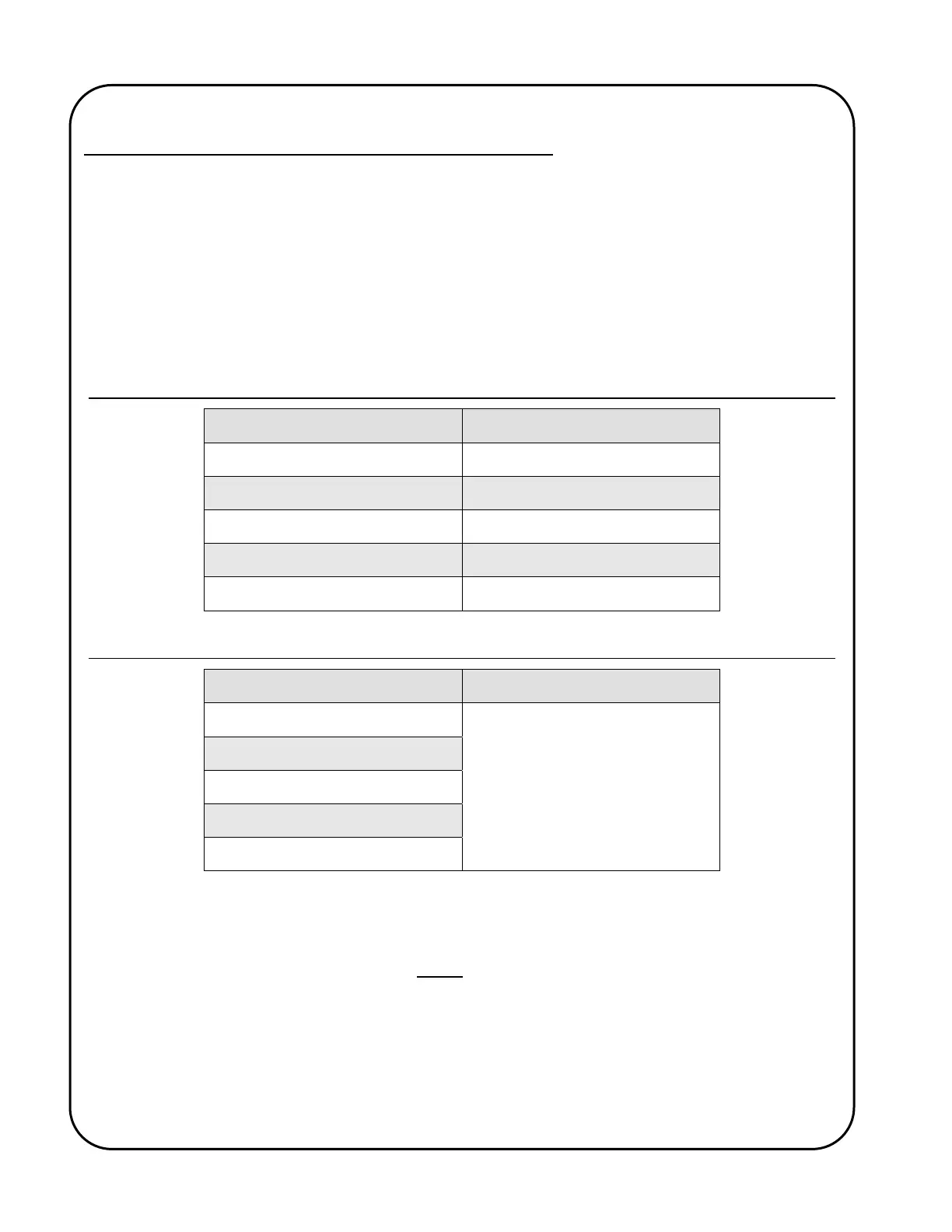

KBM

®-18 MINIMUM WORKING HEIGHT (when used with KBM®-18-069 Undercarriage Assembly)

DEGREES *TABLE HEIGHT

22.5º 21-7/8” [556 mm]

30º 21” [533 mm]

37.5º 20” [508 mm]

45º 18-3/4” [476 mm]

55º 17-1/4” [438 mm]

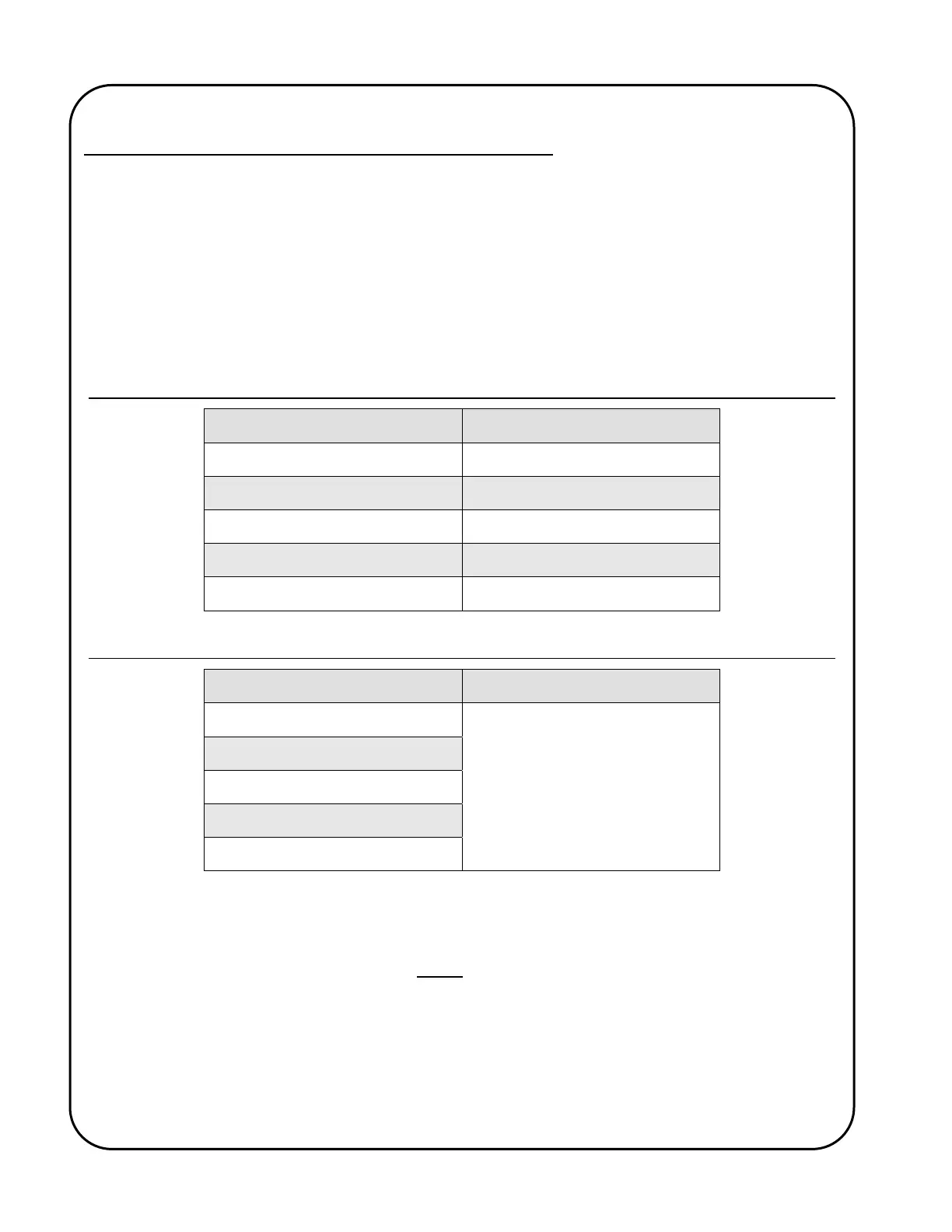

KBM

®-18 MINIMUM WORKING HEIGHT (when used with KBM®-18-080 Undercarriage Assembly)

DEGREES *TABLE HEIGHT

22.5º

35” [889mm]

30º

37.5º

45º

55º

* This is an absolute minimum height and should be used as a guide only. Most bevelling

will be 1/2” [12.7 mm] to 1” [25.4 mm] higher than above.

IMPORTANT: The KBM

®

-18 Undercarriage Assembly is equipped with spring loaded casters

designed to accommodate slight floor to work table height variances, however,

if the table height (work-piece) becomes too low (springs unable to compress

any more), machine damage will likely occur.

Loading...

Loading...