25

1

2

3

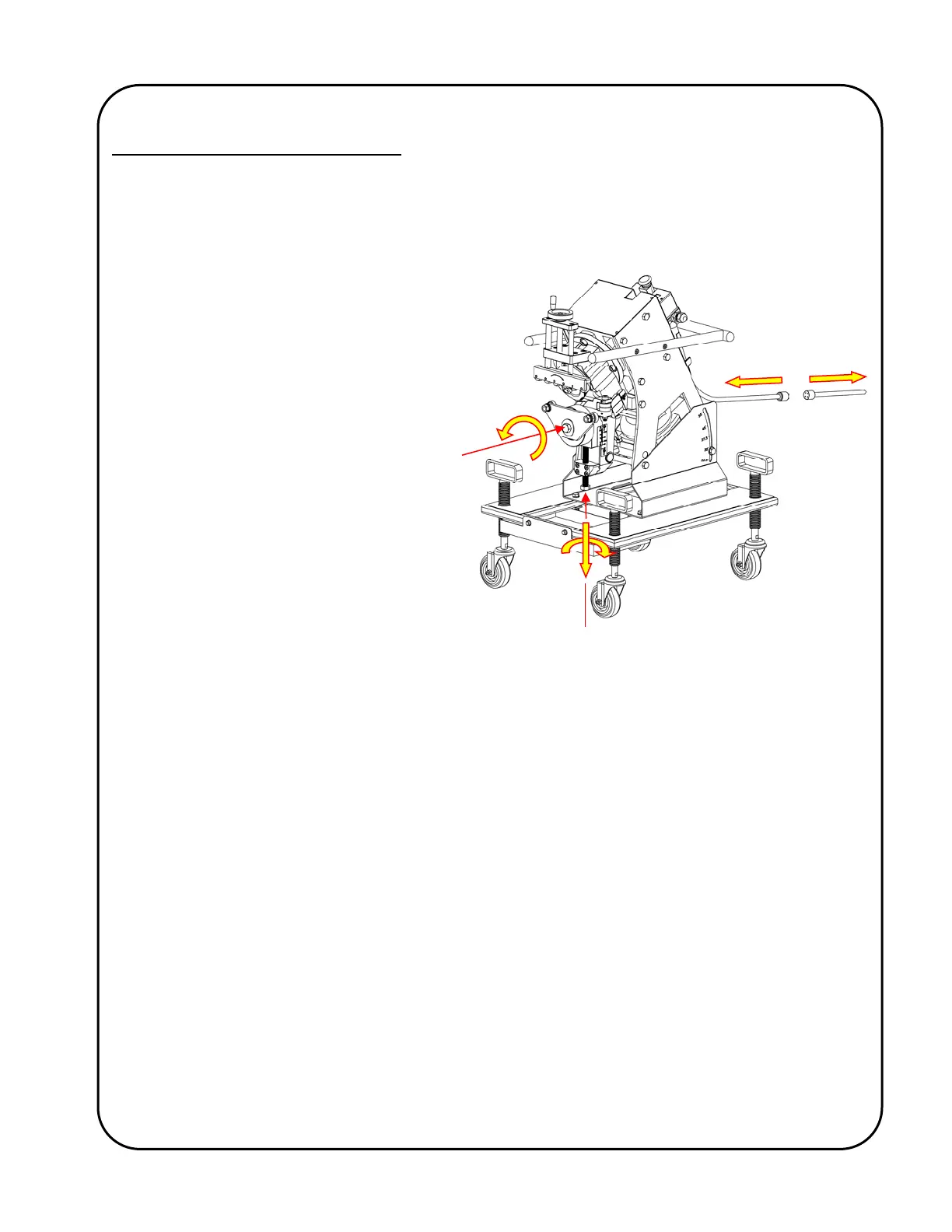

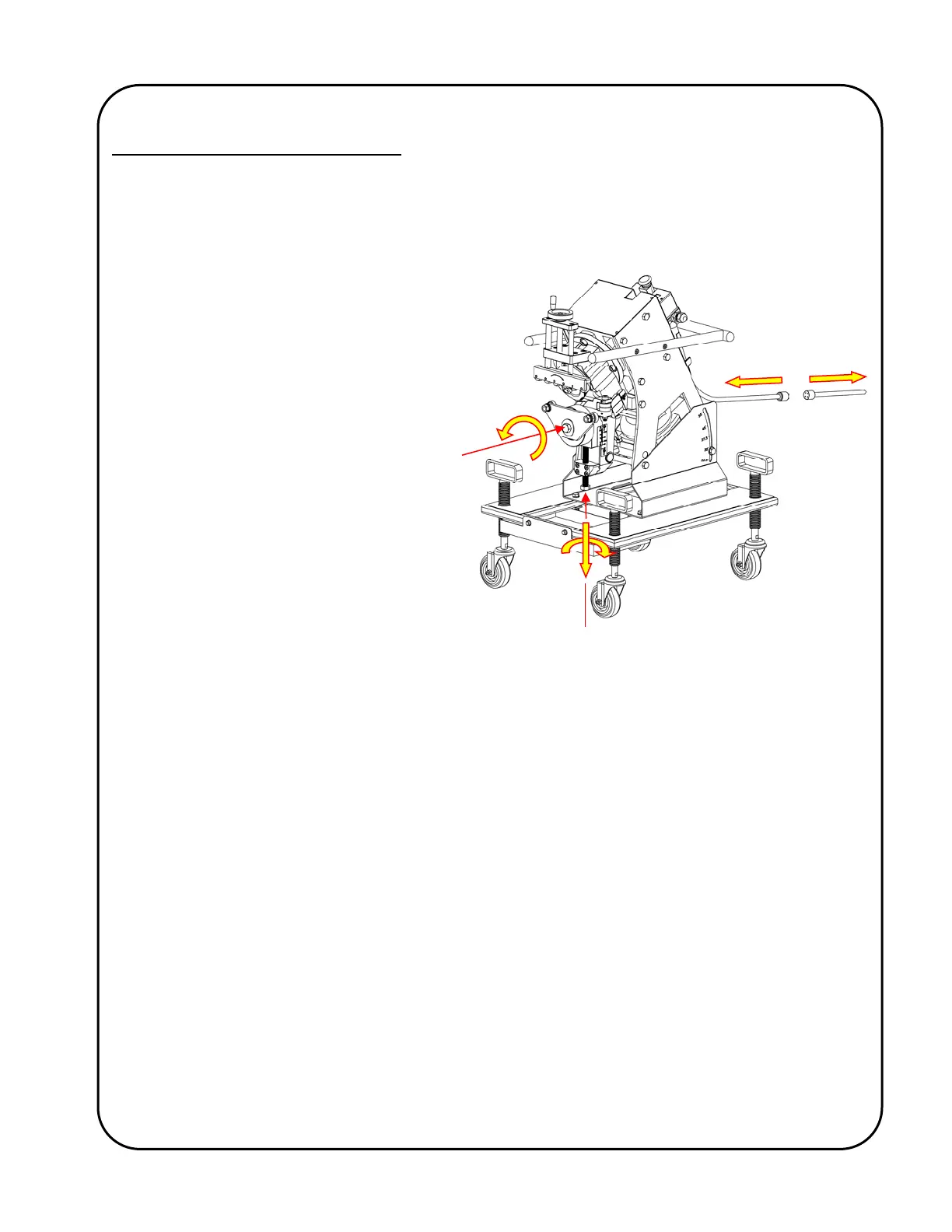

INTERRUPTED MATERIAL FEED

Material feed may be interrupted when the cutter slips due to several possibilities, such as worn

cutters, excessive external forces etc.. Should interruption of the material feed occur, do not try to

move the machine with the cutter engaged in the cutting position, or shake the machine or

plate, as this is likely to break the cutter. Proceed as follows:

1. Positively isolate/disconnect the

AC power supply.

2. Clean the area around the Main

Roller and Slide Base Assembly,

then loosen the Slide Base

Clamping Bolt.

3. Lower the Slide Base Assembly

by turning the Slide Base

Adjusting Bolt counter-clockwise.

4. Disengage the cutter from the

plate being bevelled.

5. Draw the machine back from the

plate and grind off any

projections from the bevelled

surface.

6. Rectify the problem that caused

the interruption (i.e. worn cutter; too large of a cut; incorrect height adjustment; etc.).

7. Readjust the machine settings. IMPORTANT: Ensure that no dirt or other contaminant

has been trapped behind the Main Roller, or behind the Slide Base, and ensure that

the Slide Base is seated properly, before FIRMLY re-tightening the Slide Base Clamping

Bolt.

8. Reconnect the AC power supply.

9. Restart the machine and bevel operation.

Loading...

Loading...