Page 1 of 4

50-60 Hanover Road, Florham Park, New Jersey 07932

Valves & Actuators

e

MCMXCVII All Rights Reserved.

Printed in U.S.A.

Installation & Maintenance Instructions

SERIES

Form No.V8501

FUEL GAS SERVICE

2-WAY PILOT-OPERATED OR DIRECT - ACTING SOLENOID VALVES

NORMALLY CLOSED OPERATION Ċ 3/4I, 1I, OR 1 1/2I NPT

K3A6

K3A7

Service Notice

Except for coil replacement, the Series K3A6 and K3A7 are

not repairable. When any performance problems are

detected during routine inspection, replace valve

immediately.

DESCRIPTION

Series K3A6 and K3A7 valves are 2-way normally closed

solenoid valves designed for fuel gas service. Series K3A6 is

a pilot-operated solenoid valve, while Series K3A7 is

direct-acting. Valve bodies are made of rugged aluminum

with trim and internal parts made of steel and stainless steel.

These valves are provided with a general purpose junction box

solenoid enclosure.

Provisions for Pressure and Seat Leakage Testing

Series K3A6 and K3A7 valves are provided with two 1/8I NPT

tapped and plugged holes (pressure taps). The upstream

tapped and plugged hole is on the side of the valve body;

downstream on the bottom of the valve body. One upstream

for pressure testing; one downstream for seat leakage testing.

Leakage testing frequency shall be at least annually in

accordance with NFPA-86 or original equipment

manufacturer recommendations. For instructions, refer to

section on Testing for Internal (Seat) Leakage and Figure 3.

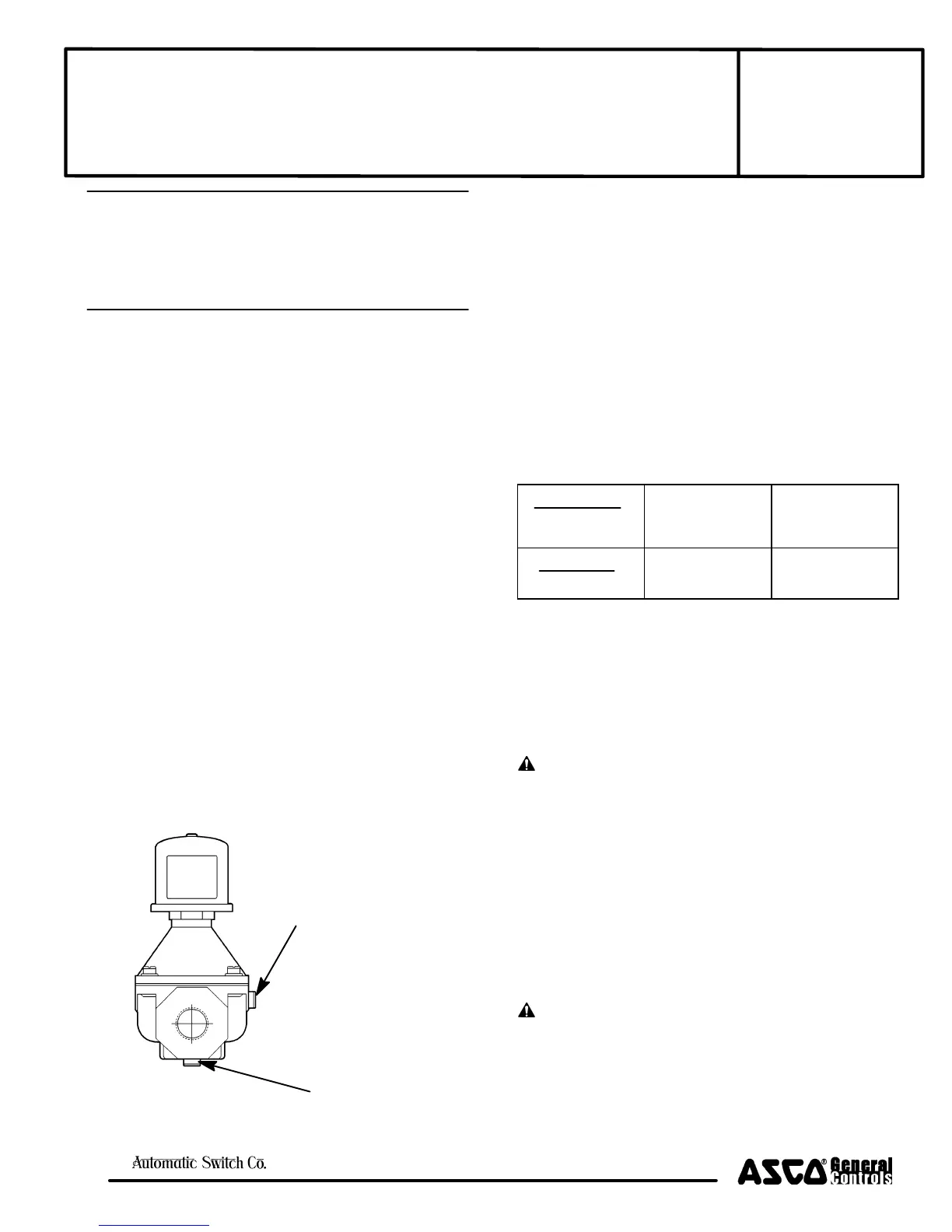

Figure 1. Provisions for pressure and seat leakage testing.

Partial view of valve body showing location

of tapped and plugged holes for pressure

and seat leakage testing

on bottom of valve body

for downstream seat

leakage testing

on side of valve body

for upstream pressure

testing

Pipe plugs are 1/8I NPT

(use 3/16I Hex Key Wrench)

Tapped and pluged hole

(pressure tap)

Tapped and pluged hole

(pressure tap)

OPERATION

Normally Closed: Valve is closed when solenoid is

de-energized; open when energized.

Note: No minimum operating pressure differential required.

INSTALLATION

Check nameplate for correct catalog number, pressure,

voltage, frequency, and service. Never apply incompatible

fluids or exceed pressure rating of the valve. Installation and

valve maintenance to be performed by qualified personnel.

Temperature Limitations

Coil Class

Temperature

Rating

Nominal

Fluid

Temperature

Ambient

Temperature

Range

F

311_F (155_C)

77_F(25_C)

-40_F (-40_C) to

175_F (80_C)

Positioning

Valve must be mounted with solenoid vertical and upright or

in a horizontal position only. Valves equipped with rainproof

housings (W in the 3rd character position of the valve catalog

number) must be mounted in a vertical and upright position

only.

Piping

CAUTION: Piping must comply with applicable

local and national codes and ordinances, including the

National Fuel Gas Code ANSI Z223.1/NFPA No. 54.

Connect piping to valve according to flow arrow on bottom of

valve body. Apply pipe compound sparingly to male pipe

threads only. If applied to valve threads, the compound may

enter the valve and cause operational difficulty. Avoid pipe

strain by properly supporting and aligning piping. When

tightening the pipe, do not use valve or solenoid as a lever.

Locate wrenches applied to valve body or piping as close as

possible to connection point. Valve should be checked for

external leakage at piping connections after installation, see

Testing for External Leakage section.

CAUTION: To avoid damage to the valve body, DO

NOT OVERTIGHTEN PIPE CONNECTIONS. If Teflon*

tape, paste, spray, or similar lubricant is used, use extra

care when tightening due to reduced friction.

*DuPont's Registered Trademark

Loading...

Loading...