2017_E_TYPE-HL.doc Page 32 of 55 24-Oct-2017

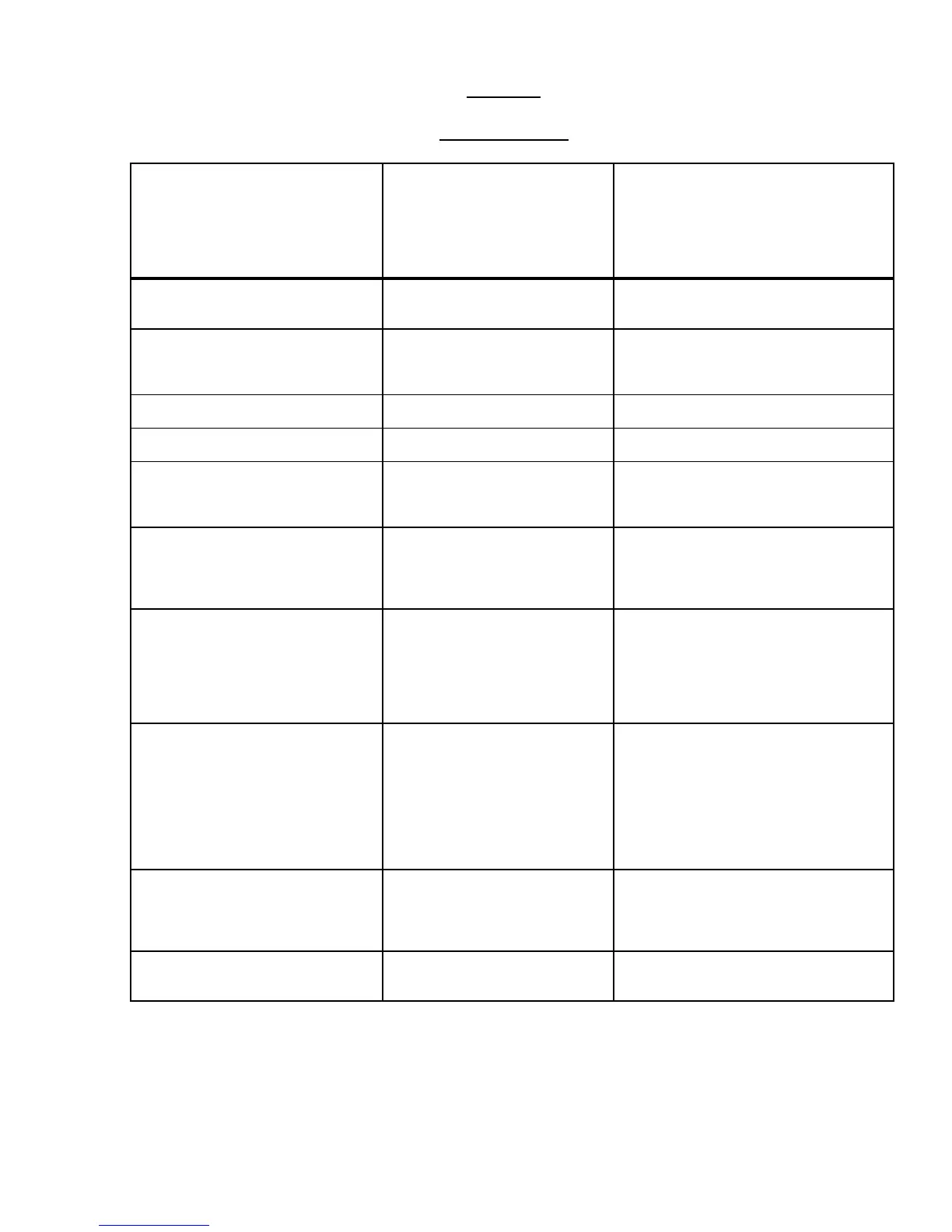

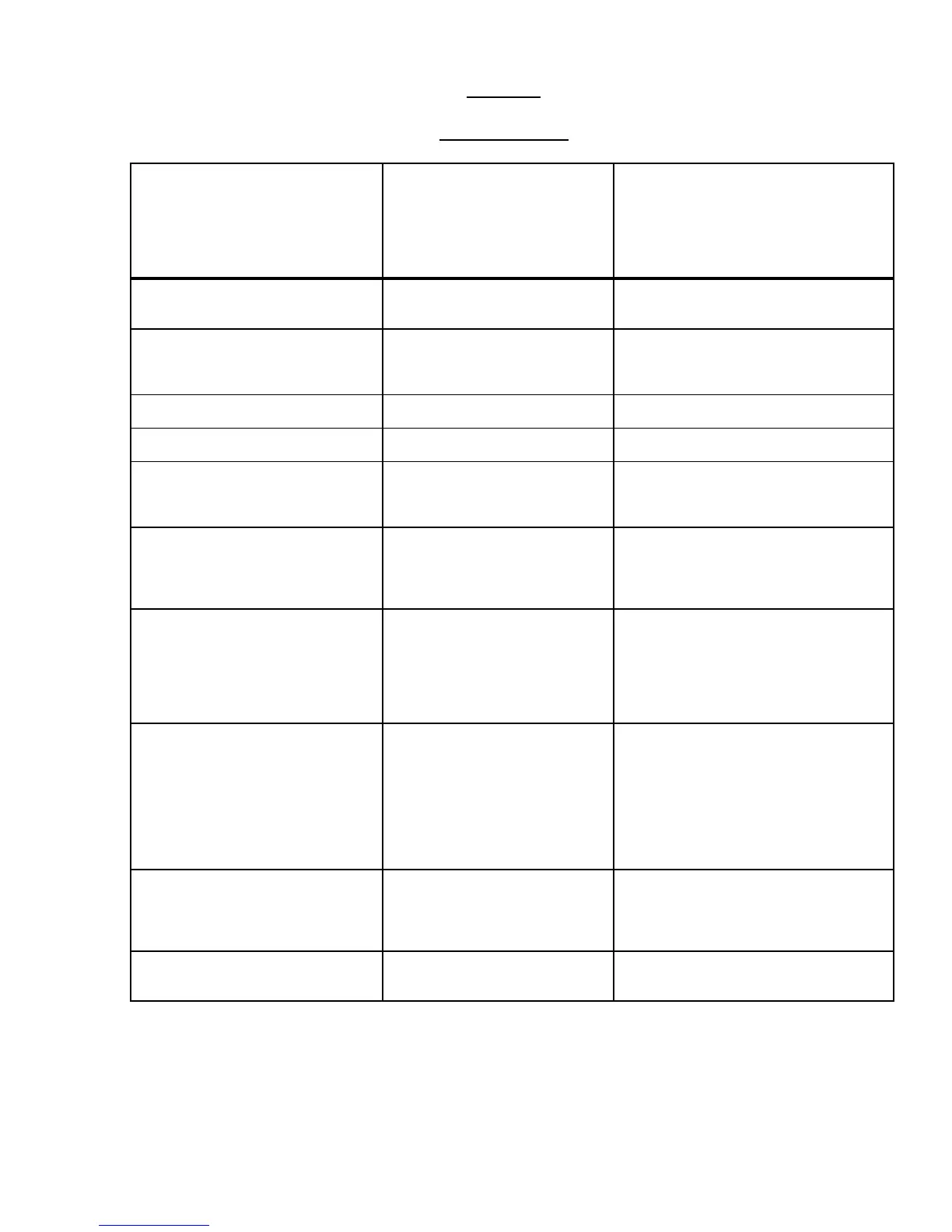

Table 4.1

Firing Sequence

System on

TE1 (process controller)

TE2 (oxidizer controller)

TE3 (process high temp controller)

TE4 (high temp safety controller)

PBC 1 (7800 module process)

OBC 2 (7800 module oxidizer)

Energies and illuminates PV (process value)

and SV (set value)

CR9 energizes (process high temp relay)

CR8 energizes (high temp safety relay)

Electronic circuits energized

Electronic circuits energized

Press RUN/RESET on process controller

to start selected program

SUB1 closes

CR7 (cycle start) energizes

CR7-1 closes

OPC (proof of closure) proves

PPC (proof of closure) proves

RCL illuminates (system light)

CR2 energizes (process blower relay)

CR3 energizes (process proof of closure)

B1 blower motor starts (optional)

st

TR1 (purge timer) allows process blower

to blow 4 volumes of air into oven.

PAS1 closes (process air switch)

CR11 energizes TR1 (purge timer)

TR1-2 closes

CR2-1 closes, CR1-2 opens (process blower

relay)

CR1 energizes (oxidizer burner relay)

OM1 starts (oxidizer blower)

OAS1 closes (oxidizer air switch)

OBC1 energizes (oxidizer burner)

OLGP1 closed if gas pressure is adequate

OPV1 (oxidizer pilot flame) opens and allows

4 seconds of gas

OIT1 (oxidizer ignition) sparks for 4 seconds

OUV1 (oxidizer scanner proves)

OR1-1 closes

OR1 (oxidizer main gas valve relay) energizes

Holding coil for OPC

OMV (oxidizer main gas valve) opens

TE2 operates Hi Lo contact on OMV oxidizer

main gas valve (SEE NOTE 1)

PL2 illuminates (oxidizer Hi Fire light)

OPL1 illuminates (oxidizer gas on light)

CR6 (Proof of temp) ensures that the

oxidizer chamber is at 1400 degrees F

before energizing the process burners

PBC1

PAS1 closes (process air switch)

CR11-2 closes

PM1 starts (1

st

process blower)

CR11 energizes

WPS1 is proven

PLGP1 closed if gas pressure is adequate

PBC1 energizes (1

st

process burner)

(SEE NOTE 3)

PPV1 (process pilot flame) opens and allows

4 seconds of gas

st

process ignition) sparks for 4 sec

PUV1 (1

st

process scanner proves

flame in .8 seconds)

PR1 closes

TE1 - OUT1 process Hi/Lo contact on PMV

process main gas valve (SEE NOTE 2)

PPV1 solenoid valves open

PPL4 illuminates (1

st

process gas on light)

CR7 de-energies

ALL devices open (end of cycle)

Loading...

Loading...