HAMWORTHY HEATING LTD

53

FLEET V series

500001213/G

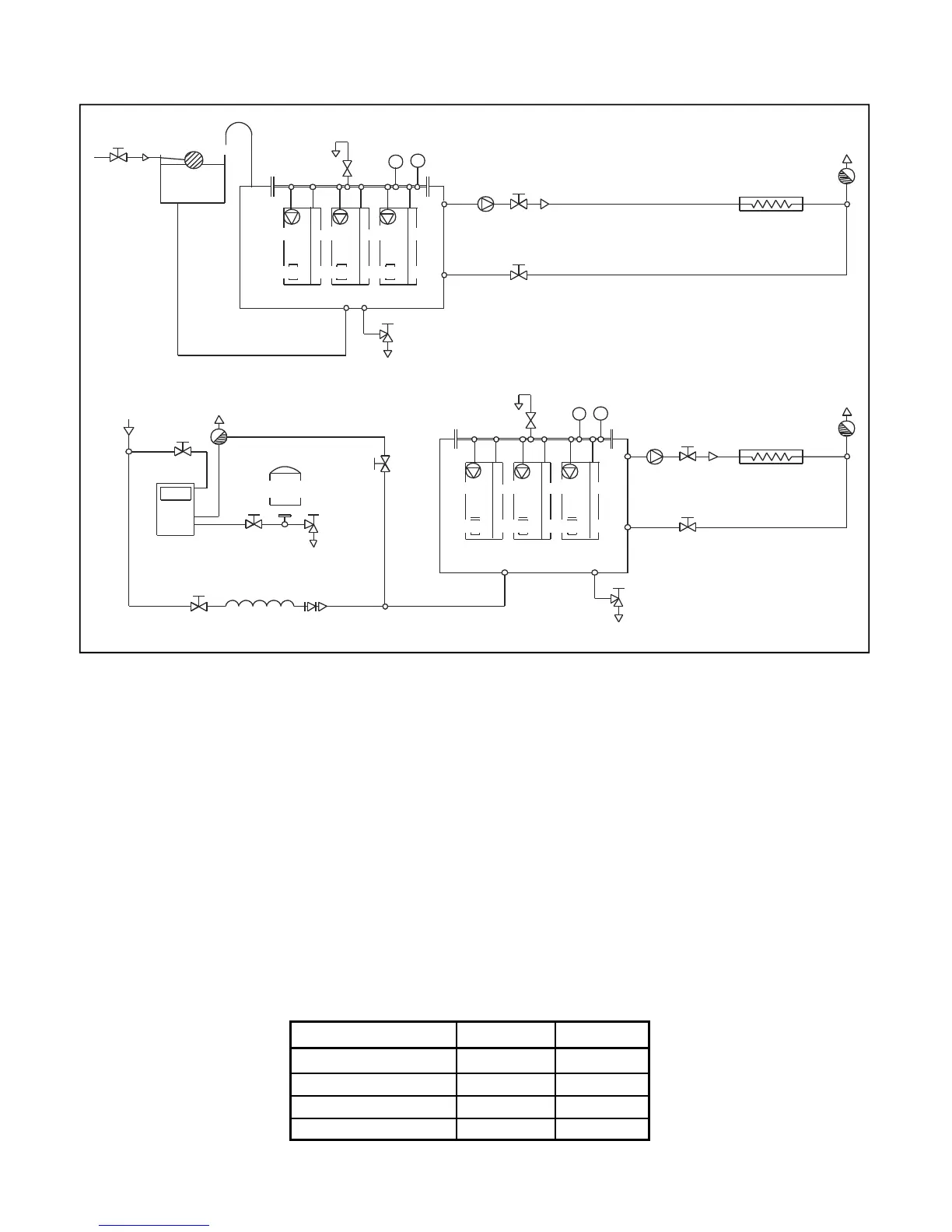

Figure E1.1 - Typical Piping Layouts

VENTED SYSTEM: Single pipe header

Mains water

Feed

pipe

expansion

Feed &

tank

valve

Float

Valve

Safety

valve

Drain

Expansion pipe

Pressure &

P

gauges

Temperature

T

Module

Module

Hamworthy Modular Boilers

Hamworthy Modular Boilers

1

1

Module

Module

2

2

Module

Module

3

3

Valve

Circulation pump

Valve

(System)

Automatic

Heating load

Air Vent

Circulation pump

Drain

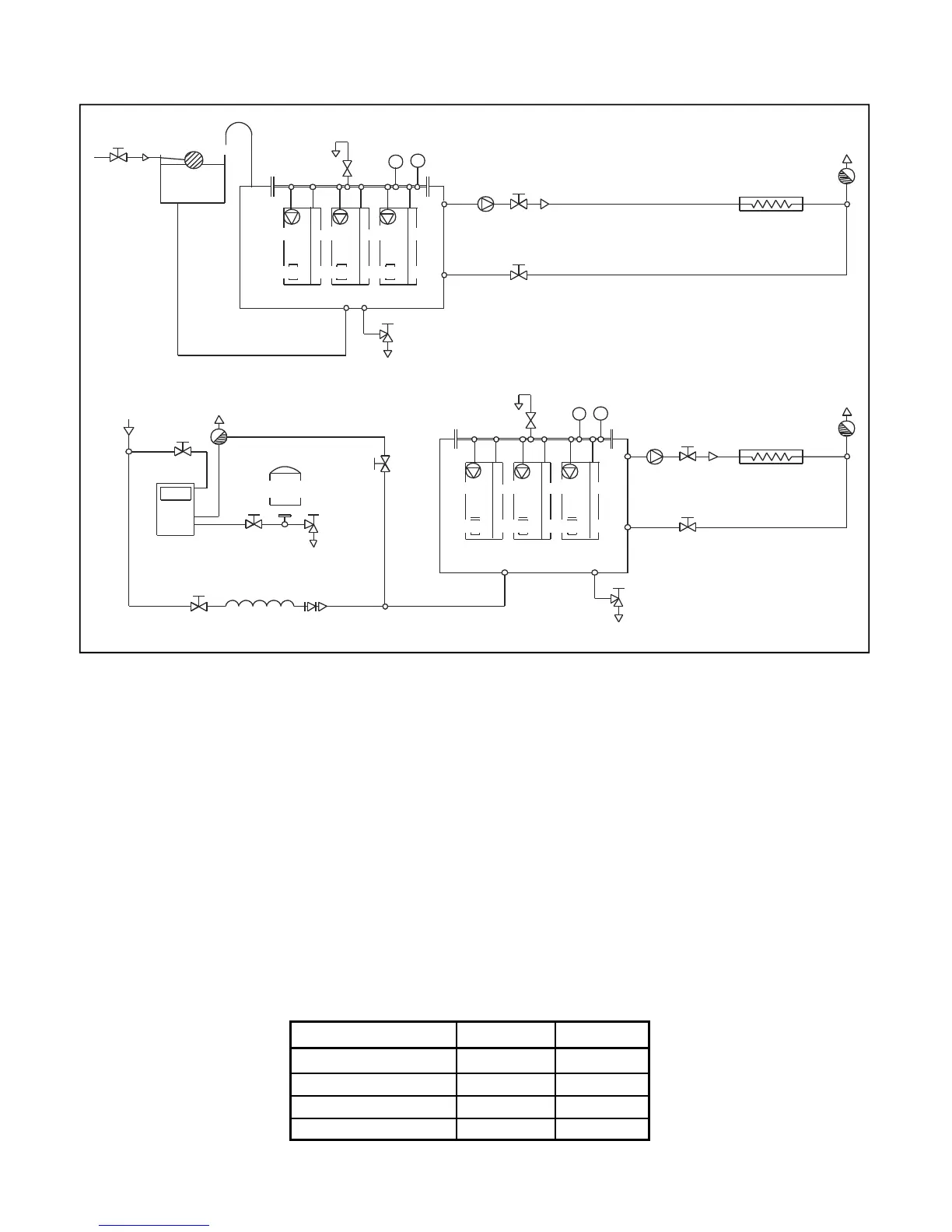

UNVENTED SYSTEM: Single pipe header

Temperature

gauges

Pressure &

Safety

valve

P

T

Heating load

Automatic

Air Vent

Valve

(System)

Valve

Lockshield

valve

Mains water

Lockshield

valve

Drain

valve

vessel

Tem porary

fill line

valve

Lockshield

Double

valve

check

Expansion

Air Vent

Automatic

Valve

Drain

valve

valve

Drain

Boiler Output Feed mm Vent mm

60 - 150kW 25 32

150 - 300 kW 32 38

300 - 600 kW 38 50

>601 KW 50 65

Figure E1.4 Cold Feed and Vent Pipe Sizes

E 1.13 Minimum System Water Pressure

To comply with guidance note PM5 (Health and Safety Executive), the minimum pressure requirements at the boiler are

given below as examples:-

1) Single installed boiler running at 82°C flow temperature. Minimum head required is not less than 2.0 metres or 0.2 bar.

2) Single installed boiler running at 90°C flow temperature. Minimum head required = 3.0 metres or 0.30 bar.

3) Modular boiler installation running at 82°C flow temperature and 11°C rise across system.

Minimum head required = 4.4 metres or 0.43 bar.

4) Modular boiler installation running at 82°C flow temperature and 15°C rise across system.

Minimum head required = 6.5 metres or 0.64 bar.

Loading...

Loading...