38

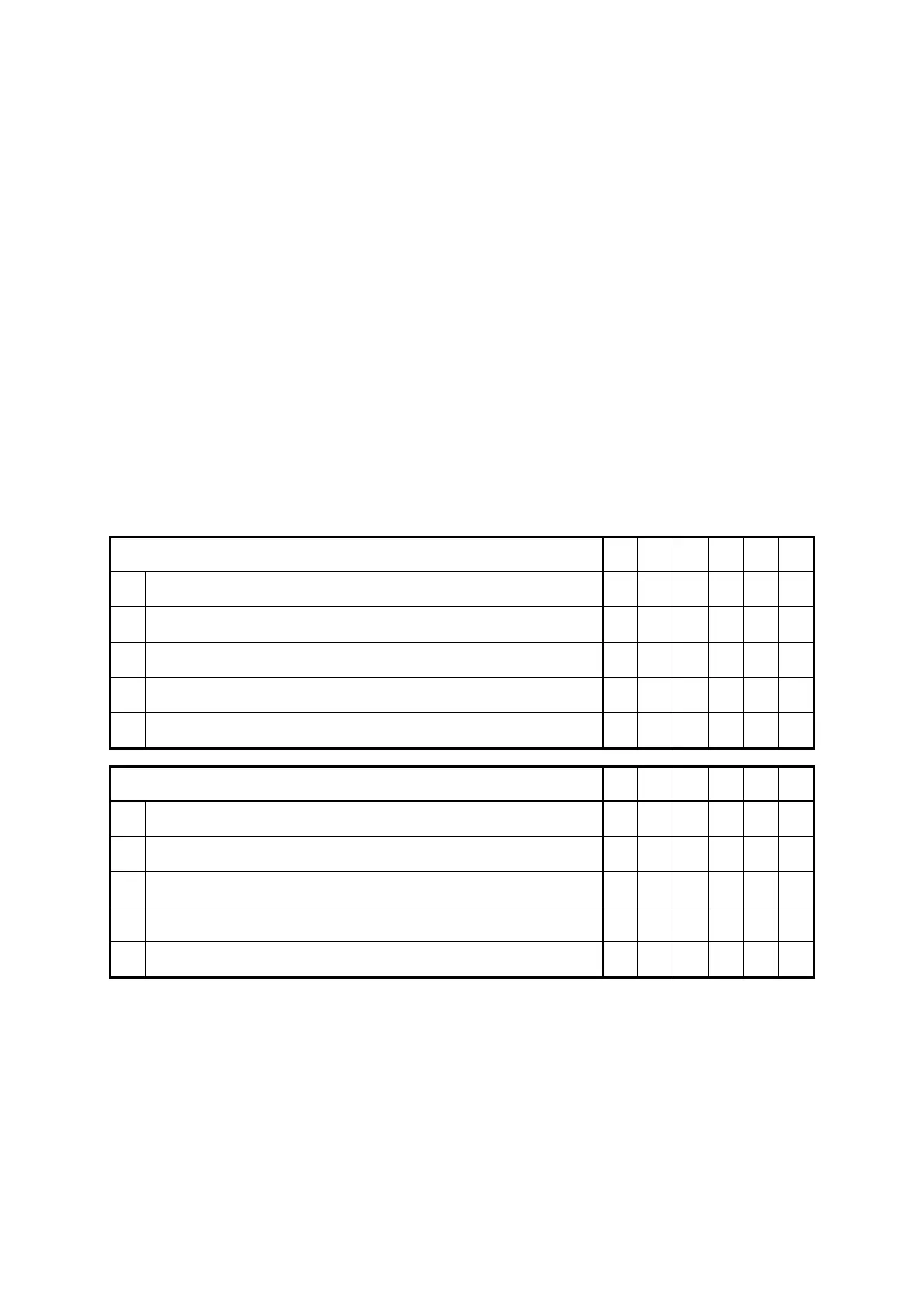

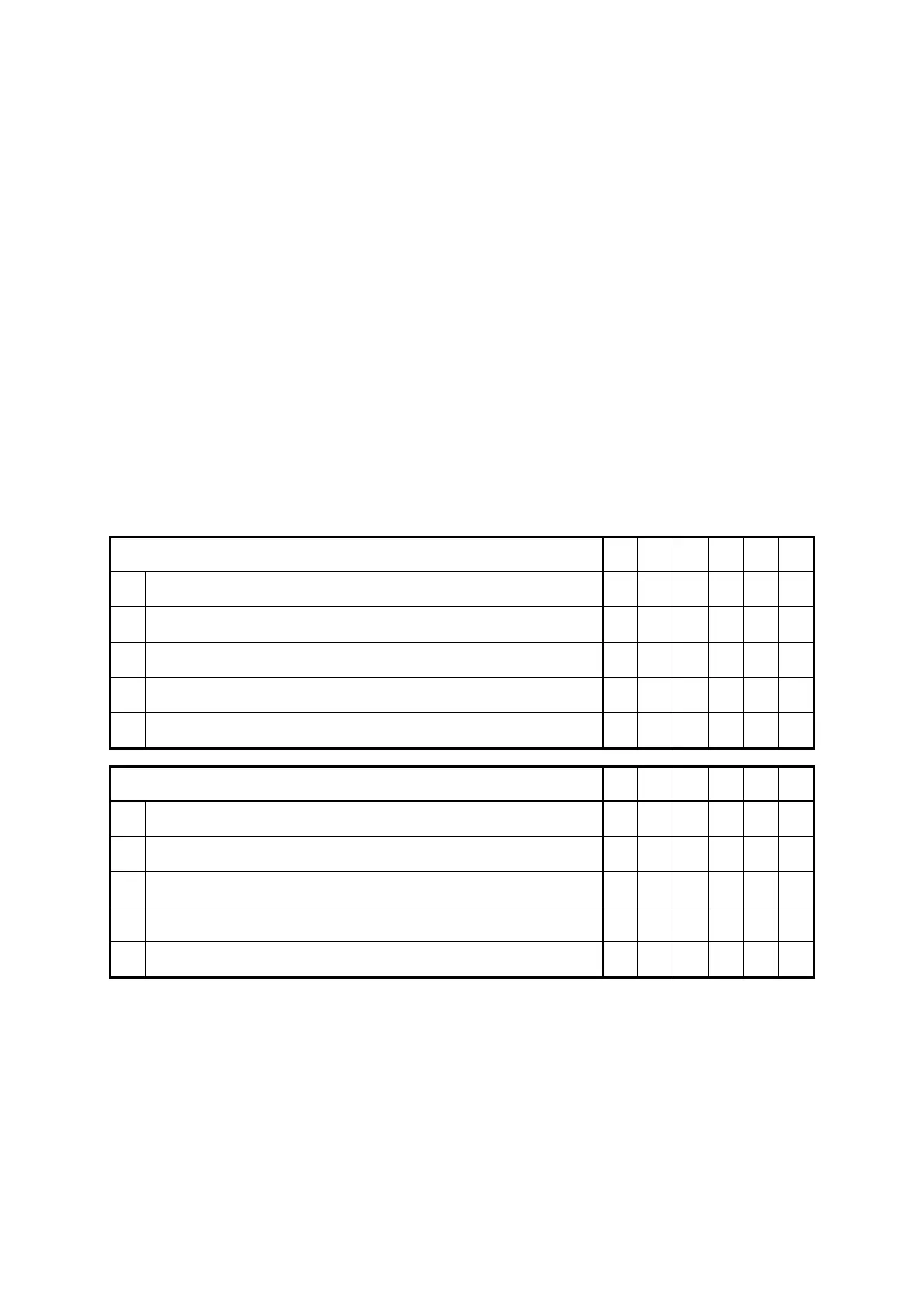

9.2 Periodic maintenance schedule

The service intervals stated are based on single shift operation under normal operating conditions.

They must be reduced accordingly if the truck is to be used in conditions of extreme dust,

temperature fluctuations or multiple shifts.

The following servicing checklist indicates the operations to be performed and the respective

intervals to be observed. Maintenance intervals are defined as:

= Every 8 service hours, at least daily

= Every 40 service hours, at least weekly

= Every 250 service hours, or at least every 1.5 months

= Every 500 service hours, or at least trimonthly

= Every 1000 service hours, or at least semiannually

= Every 2000 service hours, or at least annually

= Standard maintenance interval

=Cold store maintenance interval (in addition to standard maintenance interval)

Looseness of connecting wire

Cleanness of the battery surface

Check contactor for running

Check micromove switch for running

Check the connection among motor, battery and power unit.

Check the controller error diagnose system (First check 2 years)

Loading...

Loading...